D-type microstructure optical fiber temperature sensor based on surface plasma enhancement mechanism

A technology of surface plasmon and micro-structured optical fiber, which is applied in the field of sensors, can solve the problems of insufficient system stability, temperature cross-sensitivity of optical fiber temperature sensor, large coupling loss, etc., and achieve high stability, high temperature sensitivity, wide range, and high loss peak value Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the examples, but those skilled in the art should understand that the present invention is not limited to the following examples, and any improvements and equivalent changes made on the basis of the specific examples of the present invention are within the scope of the present invention within the scope of the claims.

[0027] Embodiment Based on the surface plasmon enhancement mechanism D-type microstructure fiber optic temperature sensor

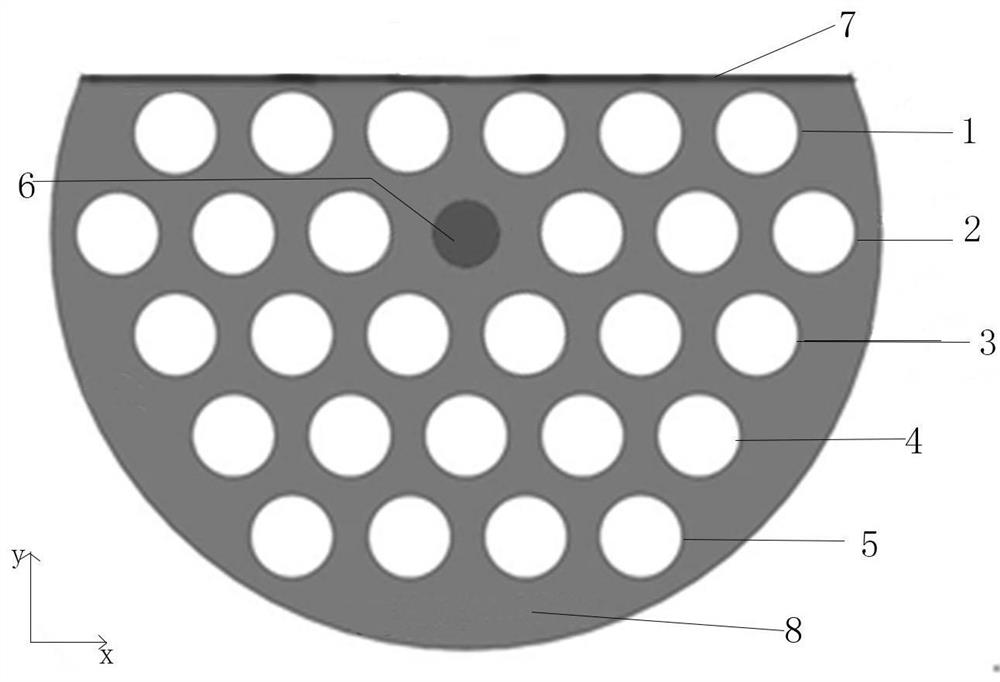

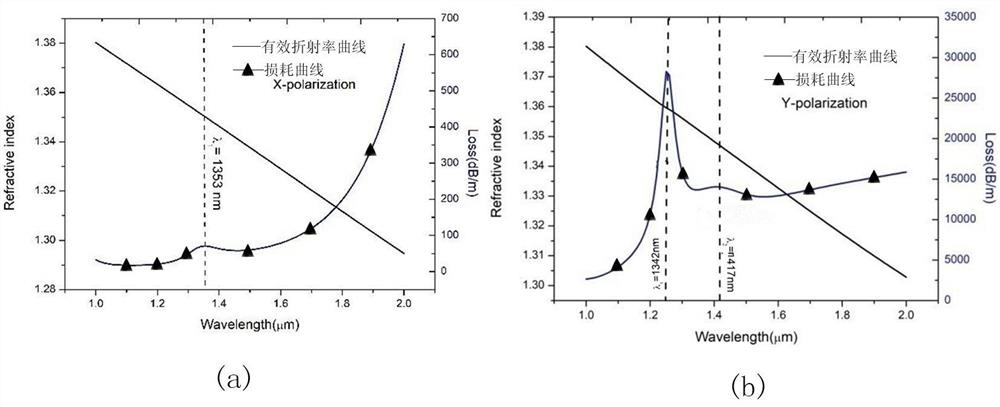

[0028] A D-type microstructure optical fiber temperature sensor based on surface plasmon enhancement mechanism, such as figure 1 As shown, it includes a background material 8, the background material 8 is surrounded by a circular arc surface and a polished plane to form a D shape, the surface of the polished plane is coated with a metal film 7, and the background material 8 is wrapped with air holes and a fiber core 6, the fiber core 6 is located at the cente...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Core diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com