Automobile and electrically driven gear-shifting execution device

A technology for actuators and shift drums, applied in mechanical control devices, transmission control, instruments, etc., can solve the problems of complex control, high cost, slow response, etc., and achieve the effect of flexible layout, low cost, and small space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In view of this, the core of the present invention is to provide an electric drive shift actuator to simplify the structure and reduce the production cost. Another core of the present invention is to provide an automobile with the above-mentioned electric drive gear shift actuator.

[0033] In order to enable those skilled in the art to better understand the solution of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

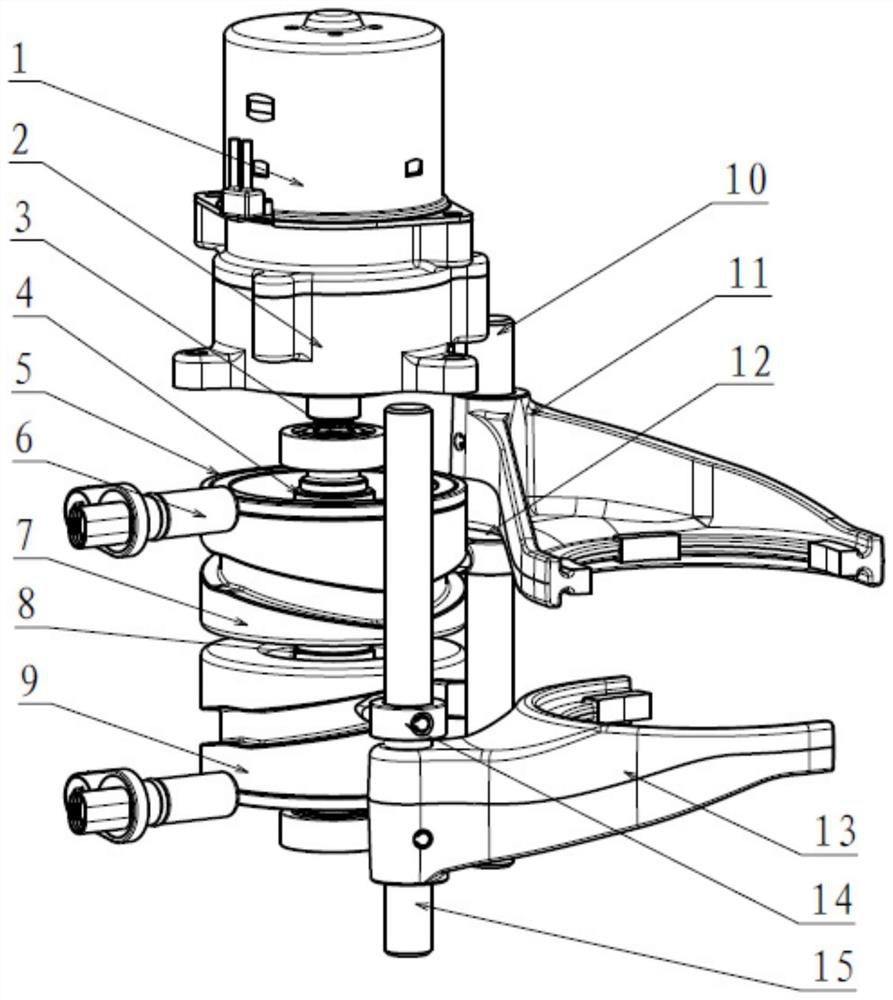

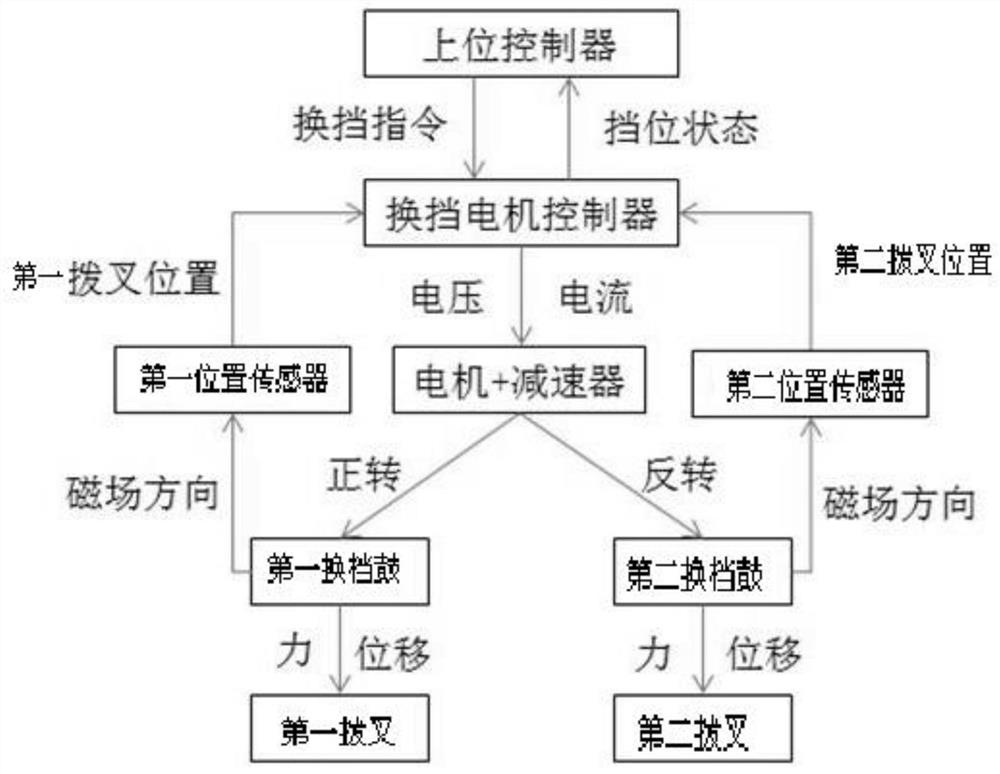

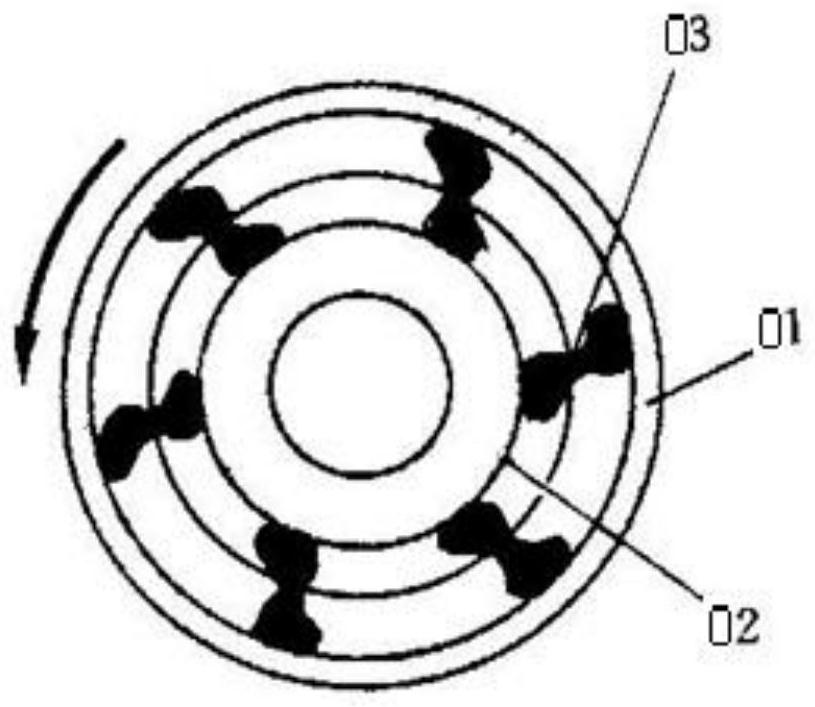

[0034] like Figure 1-Figure 5 As shown, the present invention discloses an electric drive gear shift actuator, which includes a motor 1, a reducer 2 and a shift shaft 3 that are connected in sequence, and also includes: a first one-way clutch 4, a second one-way clutch 8 , The first shift drum 7, the second shift drum 9, the first shift fork 11 and the second shift fork 13. Wherein, the inner ring of the first one-way clutch 4 and the inner ri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com