Aging accelerating method for solid-state brewed vinegar

A solid-state brewing and vinegar technology, which is applied in the field of brewing condiments, can solve the problems of time-consuming and labor-intensive food safety, uneven quality of mature vinegar, and difficulty in accurately controlling the temperature of materials, and achieve the effects of smooth progress, stable quality, and rich flavor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

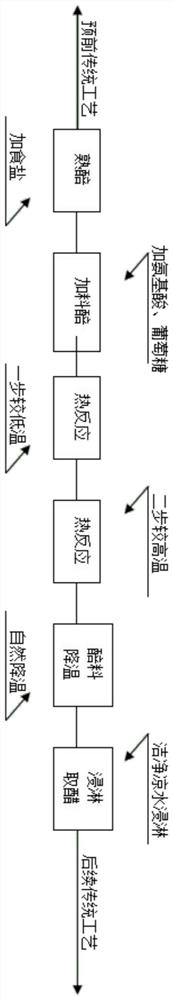

Method used

Image

Examples

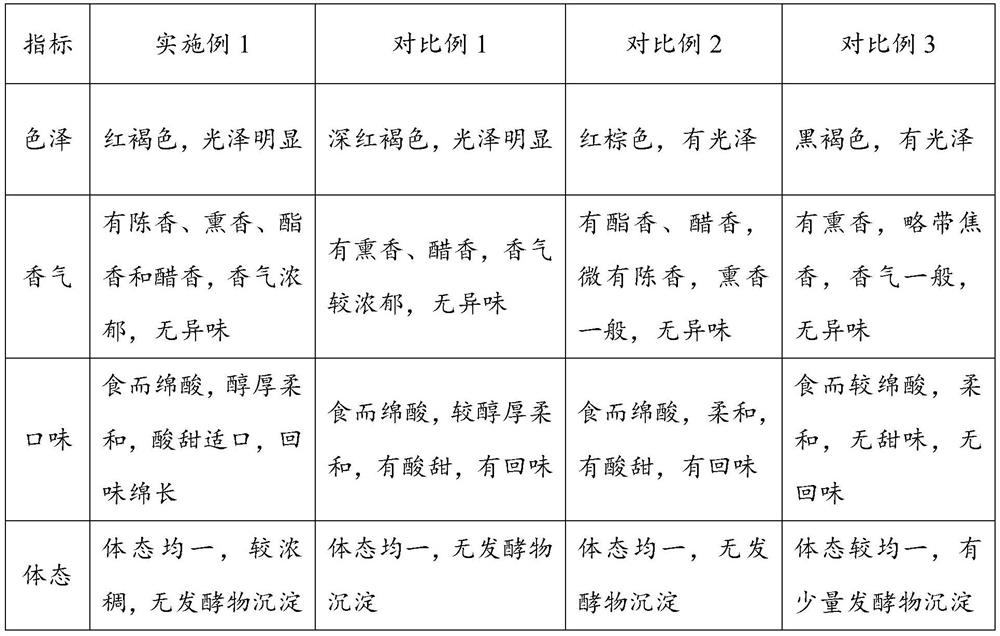

Embodiment 1

[0036]According to the traditional technical process, complete the whole process of solid-state brewing vinegar from the raw material treatment to the end of the vinegar fermentation, in the 0.5m 3 Add 5kg of salt to the vinegar material, and then ripen it for 2 days to prepare mature unstrained spirits. at 0.5m 3 Add 0.5kg of food-grade compound amino acid powder (commercially available glycerin amino acid powder and 50% of the mass of lysine amino acid powder) to the mature fermented unstrained spirits, and 5kg of commercially available food-grade glucose powder, mix evenly and place in a water bath insulation pool, and the surface of the material covers micropores For 3 μm cheesecloth, a two-step heat preservation method was performed. In the first step, the temperature of the material is 42°C for three days, and in the second step, the temperature of the material is 65°C for three days, a total of six days before and after, then stop heating and heat preservation, let the...

Embodiment 2

[0039] According to the traditional technical process, complete the whole process of solid-state brewing vinegar from raw material treatment to the end of vinegar fermentation, in 1m after the end of vinegar fermentation 3 Add 10kg of salt to the vinegar material, and ripen it for 3 days to prepare mature unstrained spirits. at 1m 3 Add 1kg of food-grade compound amino acid powder (commercially available glycerin amino acid powder and lysine amino acid powder quality 50%) to the mature fermented unstrained spirits, 10kg of commercially available food-grade glucose powder, and place them in a water bath insulation pool after uniform mixing. 4 μm thick thread cotton cloth, two-step insulation method. In the first step, the temperature of the material is 45°C for three days, and in the second step, the temperature of the material is 68°C for three days, a total of six days before and after, then stop heating and heat preservation, let the temperature of the material drop natural...

Embodiment 3

[0041] According to the traditional technical process, complete the whole process of solid-state brewing vinegar from raw material treatment to the end of vinegar fermentation, in 1m after the end of vinegar fermentation 3 Add 10kg of salt to the vinegar material, and ripen it for 3 days to prepare mature unstrained spirits. at 1m 3 Add 1kg of food-grade compound amino acid powder (commercially available glycerin amino acid powder and lysine amino acid powder quality 50%) to the mature fermented unstrained spirits, 10kg of commercially available food-grade glucose powder, and place them in a water bath insulation pool after uniform mixing. 5 μm thick thread cotton cloth, two-step insulation method. In the first step, the temperature of the material is 55°C for three days, and in the second step, the temperature of the material is 70°C for three days, a total of six days before and after, then stop heating and heat preservation, let the temperature of the material drop natural...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com