Baking and frying device used for tea oil, and use method for baking and frying device

A technology of roasting and tea oil, applied in the direction of fat oil/fat production, separation methods, chemical instruments and methods, etc., can solve the problems of laborious and laborious, cannot meet the large-scale large-scale production, and achieve the effect of enhancing the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

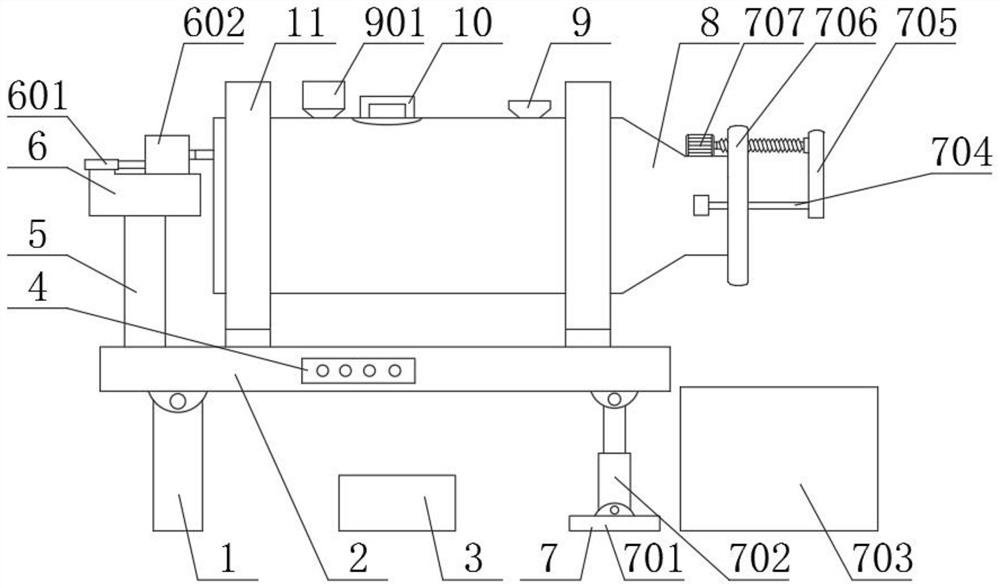

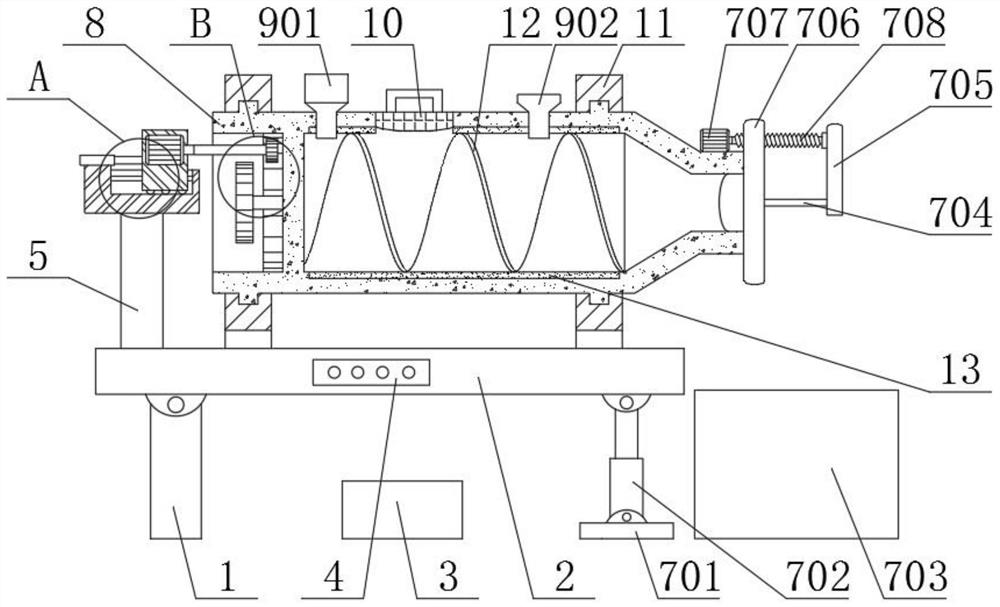

[0033] see Figure 1-8 , the present invention provides a technical solution:

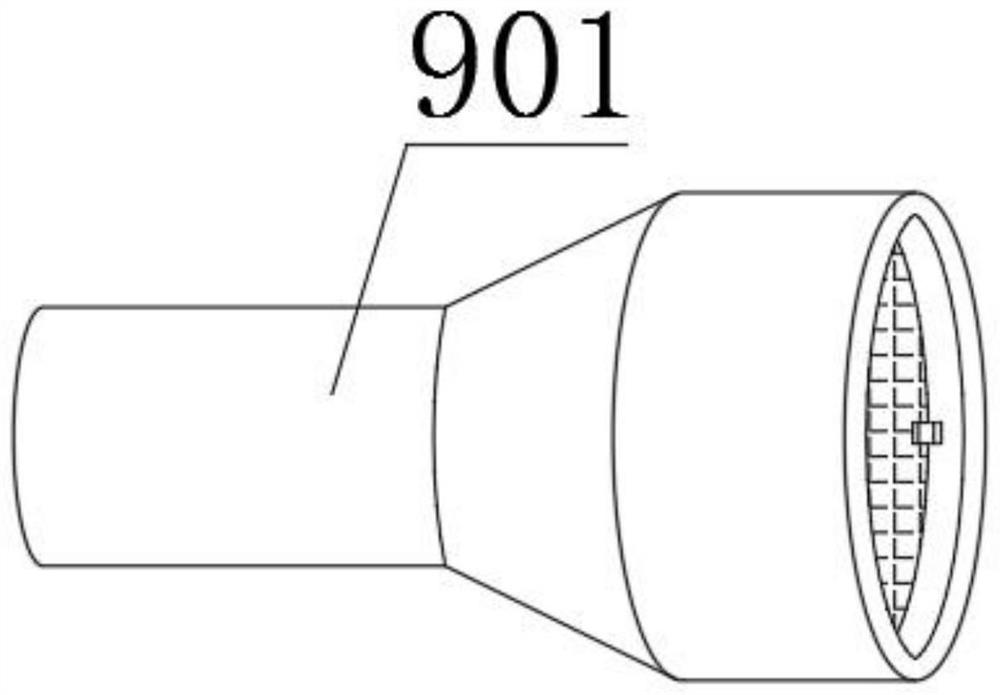

[0034] A roasting and frying device for tea oil production and its use method, comprising a support column 1, a support plate 2, a hydraulic tank 3, a rotating device 6 and a discharge device 7, the top of the support column 1 is connected to the bottom end of the support plate 2 through a hinge The left side is connected by rotation, the hydraulic tank 3 is arranged on the lower side of the support plate 2, the hydraulic tank 3 is used to provide power for the hydraulic rod 702, the front end of the support plate 2 is fixedly connected with the controller 4, and the top of the support plate 2 is fixedly connected with a support Ring 11, the support ring 11 is used to support the stir-frying tube 8, and the stir-frying tube 8 can be rotated, the inner side of the support ring 11 is connected with the stir-frying tube 8, and the inner side of the stir-frying tube 8 is fixedly connected with a spiral...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com