Replaceable modular socket structure

A modular and socket technology, applied in the direction of electrical components, coupling devices, circuits, etc., can solve the problems of inconvenient disassembly and maintenance, and achieve the effects of convenient mating, improved safety performance, and easy disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

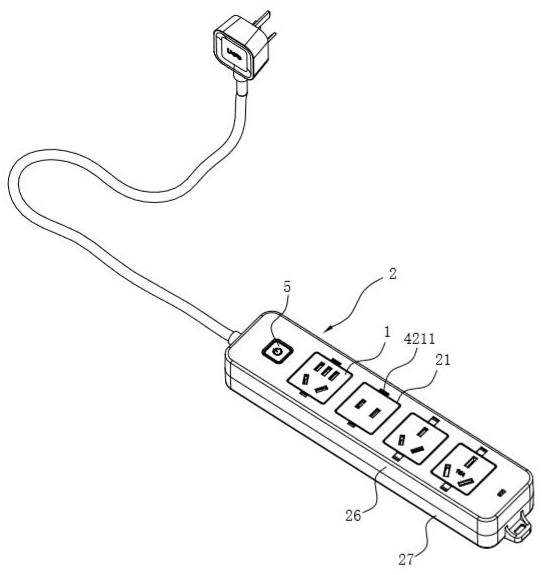

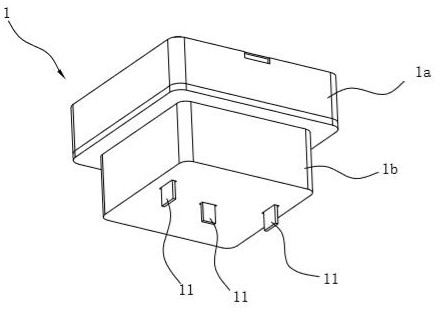

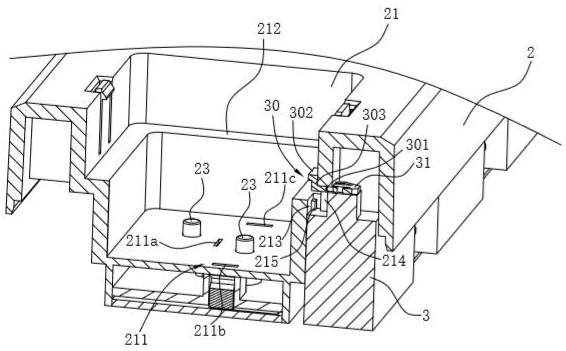

[0033] Such as figure 1 As shown in ~ 7, the replaceable modular socket structure in this embodiment includes a socket assembly 2 and a jack assembly 1, and the upper wall of the socket assembly 2 is provided with a slot 21 for detachable mating of the jack assembly 1, such as image 3 As shown, the bottom of jack assembly 1 has pins 11, correspondingly, as Figure 4 As shown, there is a socket 211 for the pin 11 to pass through on the bottom wall of the slot 21, as Figure 5 As shown, the outer bottom of the slot 21 is provided with an electrical connector 22 arranged corresponding to the socket 211 and used for connecting the pin 11 with the power supply electrical signal.

[0034] Such as image 3 As shown, the above jack assembly 1 has a first part 1a on the upper part and a second part 1b on the lower part, the width of the second part 1b is smaller than the width of the first part 1a so that the cross section of the jack assembly 1 is shaped into a T-shaped structure ...

Embodiment 2

[0043] The difference between this embodiment and embodiment 1 is:

[0044] Such as Figure 8 As shown, on the basis of Embodiment 1, the limit assembly 4 of this embodiment is provided with a chute 4213 connected with the slot 21 on the top wall of the socket assembly 2, and the outer edge of the top of the card 423 is provided with a direction The pinch plate 4231 extending in the chute 4213 has a rib 4232 on the outer edge of the pinch plate 4231 . This structure is conducive to further improving the convenience of operation. When the socket assembly 1 needs to be taken out from the slot 21, the hand clamps the rib 4232 on the buckle plate 4231 and moves it outward along the slide groove 4213, so that it can be easily The buckle 4211 is disengaged from the bayonet 411 , thereby canceling the restriction on the jack assembly 1 .

[0045] The socket assembly 2 is provided with a first elastic member 44 that can keep the card 423 springing toward the inside of the slot 21 al...

Embodiment 3

[0047] The difference between this embodiment and Embodiments 1 and 2 lies in that the structure and operation mode of the limiting components are different.

[0048] Such as Figure 9 , 10 As shown, the limiting assembly in this embodiment includes a bayonet 11a, a bayonet 41a and a drive assembly 4a, the outer wall of the jack assembly 1 is provided with a bayonet 11a, and the side wall of the slot 21 is provided with a corresponding bayonet 11a The notch 211a is arranged, and the socket assembly 2 is provided with a retractable block 41a that is arranged through the notch 211a and is mated with the bayonet 11a to limit when it is inserted into the slot 21 .

[0049] The socket assembly 2 of this embodiment is also provided with a drive assembly 4a for driving the expansion and contraction of the block 41a. Part of the drive assembly 4a is exposed on the outer wall of the socket assembly 2 and always keeps the block 41a extending into the slot 21. the trend of.

[0050] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com