Hoisting equipment and hoisting control method

A technology for lifting equipment and hangers, which is applied in the direction of load hanging components, hoisting devices, transportation and packaging, etc., and can solve the problems of inconvenient regulation and control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

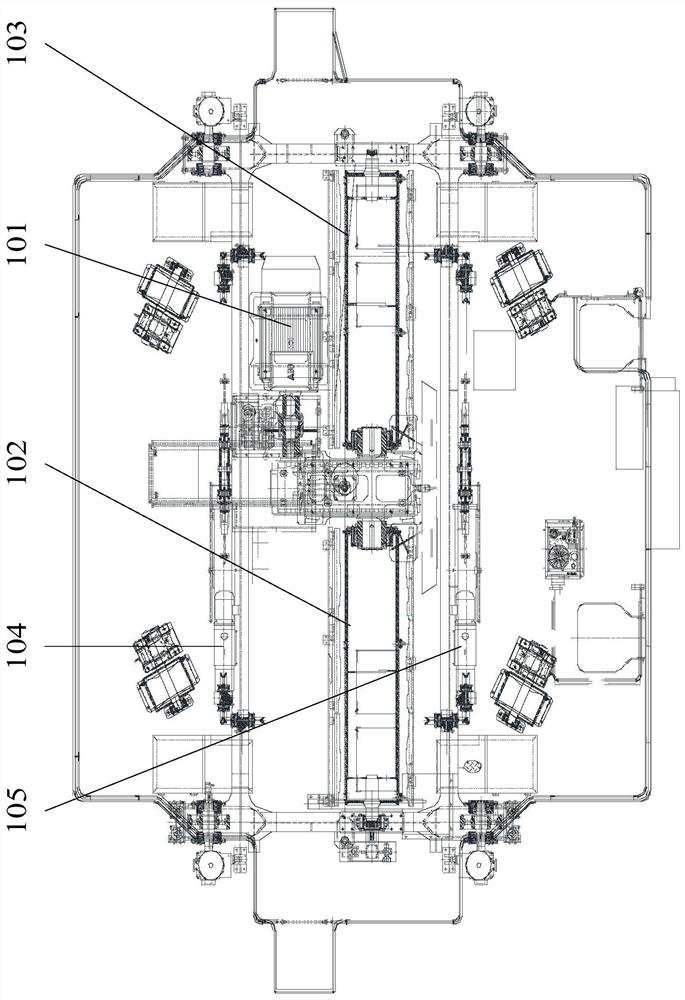

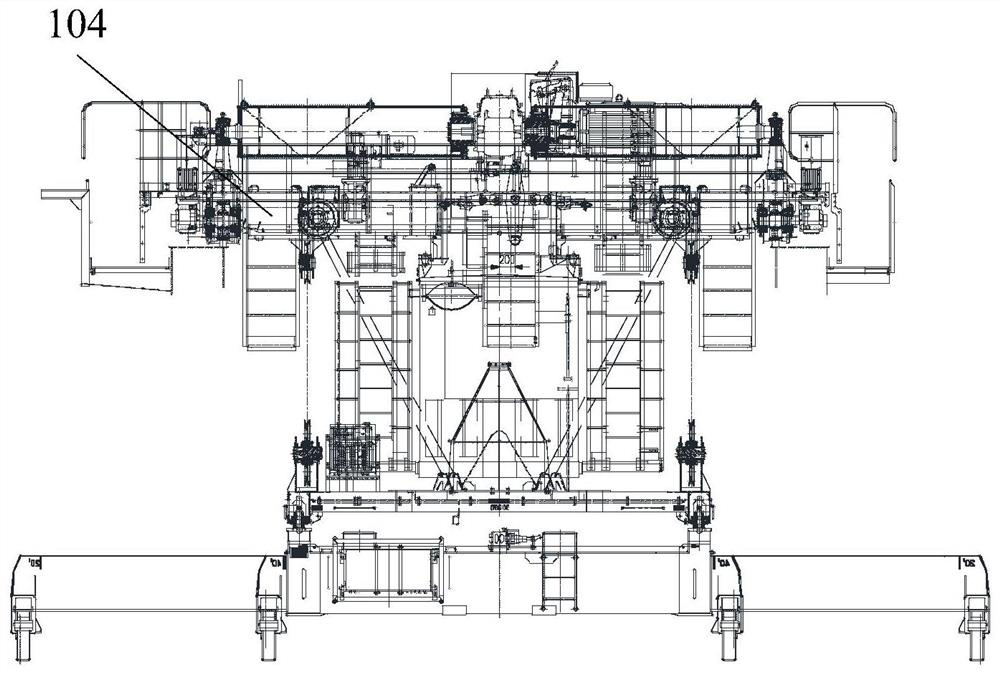

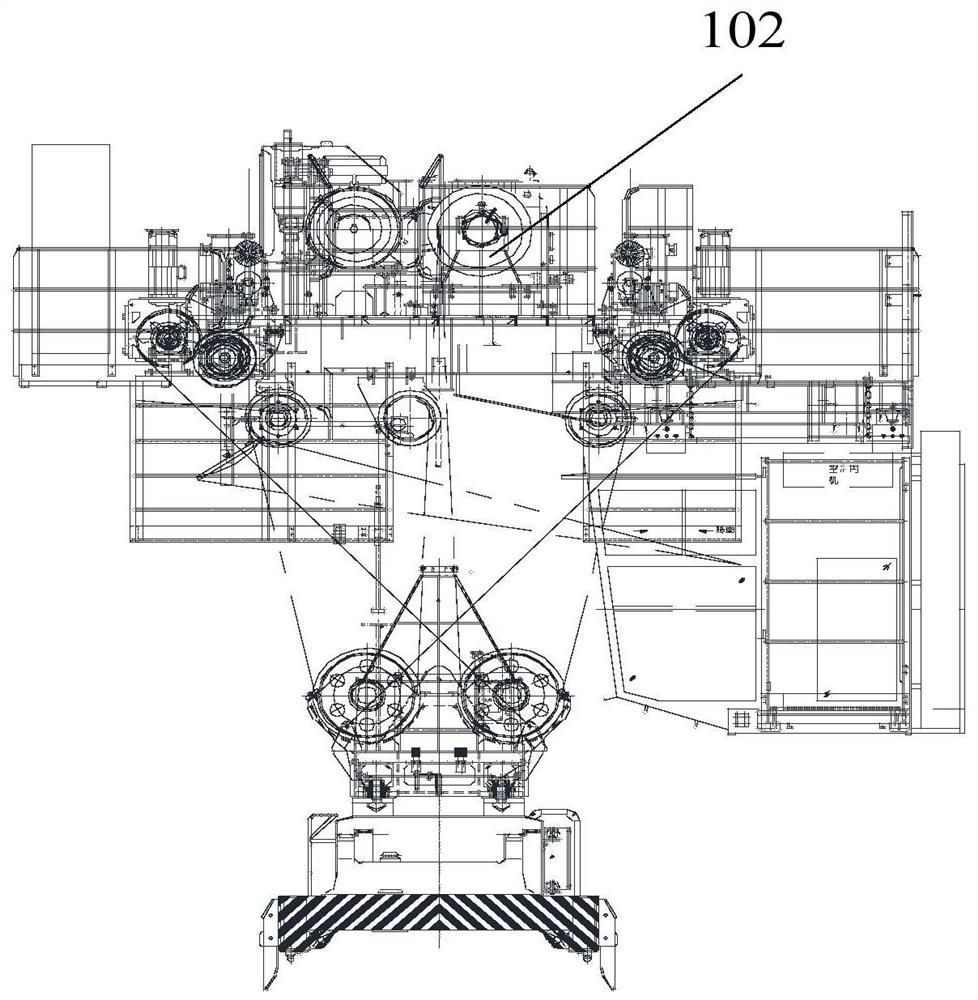

[0057] combine Figure 1-Figure 5 As shown, the present application provides a lifting device, including a hanger 140, a first drive assembly 101, a first reel 102, a second reel, a first push rod 104 and a second push rod 105;

[0058] The first driving assembly 101 can drive the first reel 102 and the second reel to rotate;

[0059] The hanger 140 is provided with two groups of first hanging joints, which are No. 1 first hanging joints and No. 2 first hanging joints; the No. 1 first hanging joints and the first hanging joints The No. 2 first hanging joint group is arranged at intervals along the width direction of the hanger 140;

[0060] The No. 1 first sling set includes two first slings, which are respectively the No. 1 first sling 108 and the No. 2 first sling. The No. 1 first sling 108 and the No. 1 first sling The No. 2 first slings are arranged at intervals along the length direction of the hanger 140; the No. 2 first sling group includes two first slings, respectiv...

Embodiment 2

[0094] The application also provides a lifting control method:

[0095] Step 100: Drive the first driving assembly, so that the first suspension rope 110 and the second suspension rope 111 are respectively wound on the first reel 102 and / or the third suspension rope and The fourth lifting rope is respectively released on the second drum; or the third lifting rope and the fourth lifting rope are respectively wound on the second drum and / or the first lifting rope 110 and the second suspension rope 111 are respectively released on the first reel 102 so that one or the other end of the hanger 140 in the length direction is tilted.

[0096] Step 200: drive the first push rod 104, the second push rod 105 is still, so that the hanger 140 rotates in the first direction or the second direction; drive the second push rod 105, the first A push rod 104 is stationary to rotate the hanger 140 in the third direction or the fourth direction.

[0097] Using the first driving assembly 101 to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com