Sanding device for processing fireproof boards

A sheet metal processing and sanding technology, used in metal processing equipment, manufacturing tools, grinding workpiece supports, etc., can solve the problems of increased labor costs and low sanding efficiency, and achieve reduced labor costs, labor, and sanding. Efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

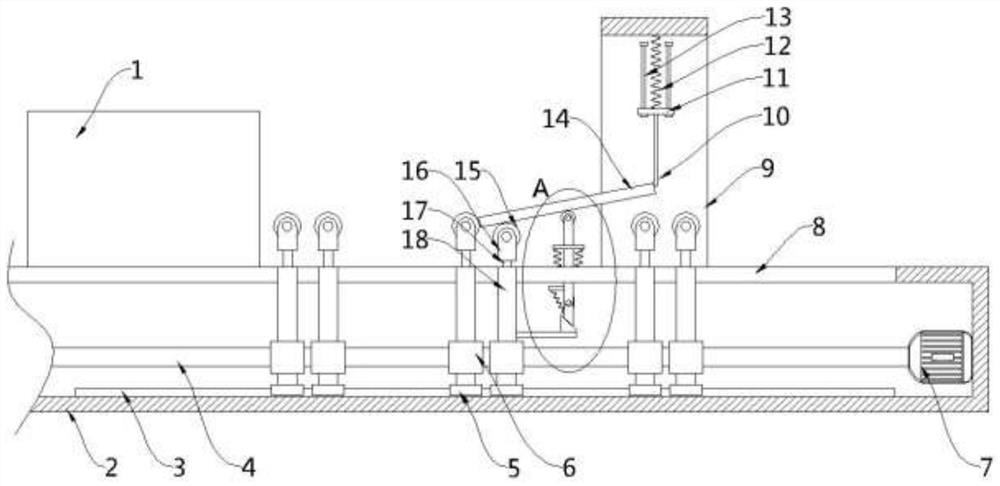

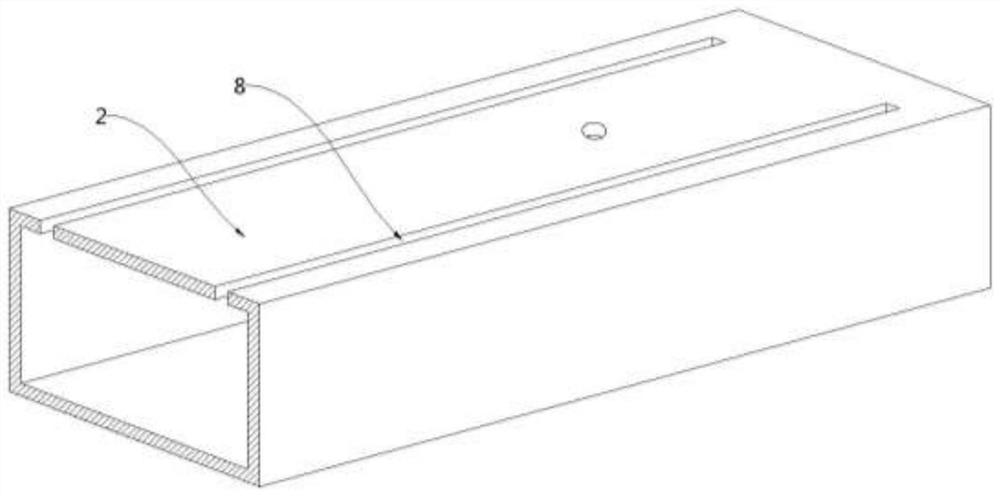

[0025] see Figure 1-4 , this embodiment provides a sanding device for processing fireproof boards, including a bottom box 2, a sanding assembly 1 arranged on the upper left side of the bottom box 2, and a top support arranged on the upper right side of the bottom box 2 Assemblies, the inside of the bottom box 2 is provided with at least three sets of supporting components for supporting the plate body 14 from left to right, and the inside of the bottom box 2 is also provided with a set for driving the supporting components along the length direction of the bottom box 2 The reciprocating drive assembly, specifically, each set of supporting assemblies includes two sets of support tubes 18, the upper parts of the two sets of support tubes 18 are telescopically fitted with support rods 17, and the bottoms of the two sets of support tubes 18 are fixed A sliding sleeve 6 is provided, and the upper part of the support rod 17 is fixedly connected with a support 16, and the upper part...

Embodiment 2

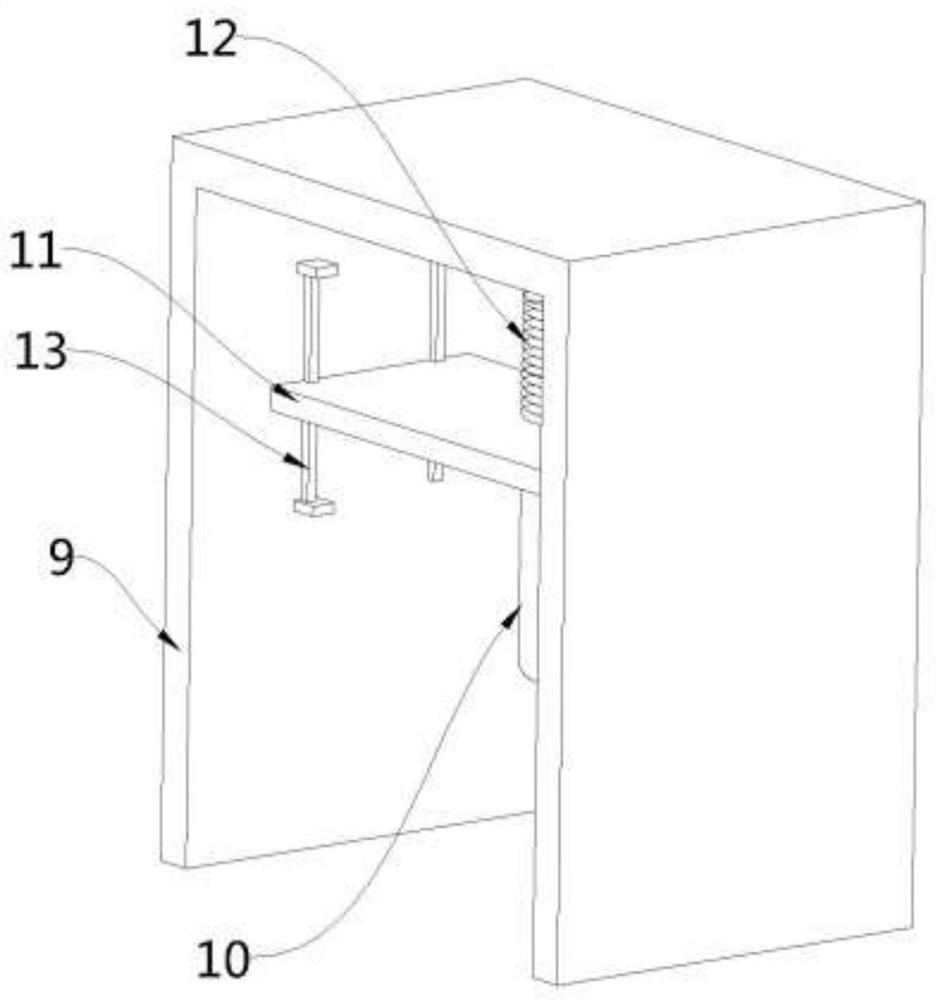

[0036] see Figure 1-2 , a sanding device for processing fireproof boards. Compared with Embodiment 1, the inner wall of the support box 9 is equipped with a second guide rail 13 distributed vertically, and the side wall of the lifting plate 11 is provided with a The second guide rail 13 is fitted with a slot (not shown), and the side wall of the lifting plate 11 slides and fits with the second guide rail 13 through the slot, which can improve the stability of the lifting plate 11 when it moves up and down.

[0037] In the embodiment of the present invention, through the arrangement of at least three sets of supporting components and supporting components, the plate body 14 can be automatically turned over after sanding treatment on the upper part of the plate body 14, and the turned-over plate body can be turned over with the cooperation of the drive assembly. 14 is transported to the inside of the sanding unit 1 again for sanding, thereby sanding the two sides of the plate b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com