Vibration source upper-mounted type environment-friendly old asphalt screening machine

A kind of asphalt old material, environmental protection technology, applied in the direction of filter screen, solid separation, grille, etc., can solve the problems of easy blockage of screen holes, adverse effects of operators, and impact on residents' environment, so as to improve screening efficiency and avoid Unsmooth sieving and avoiding the effect of sieve hole clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings.

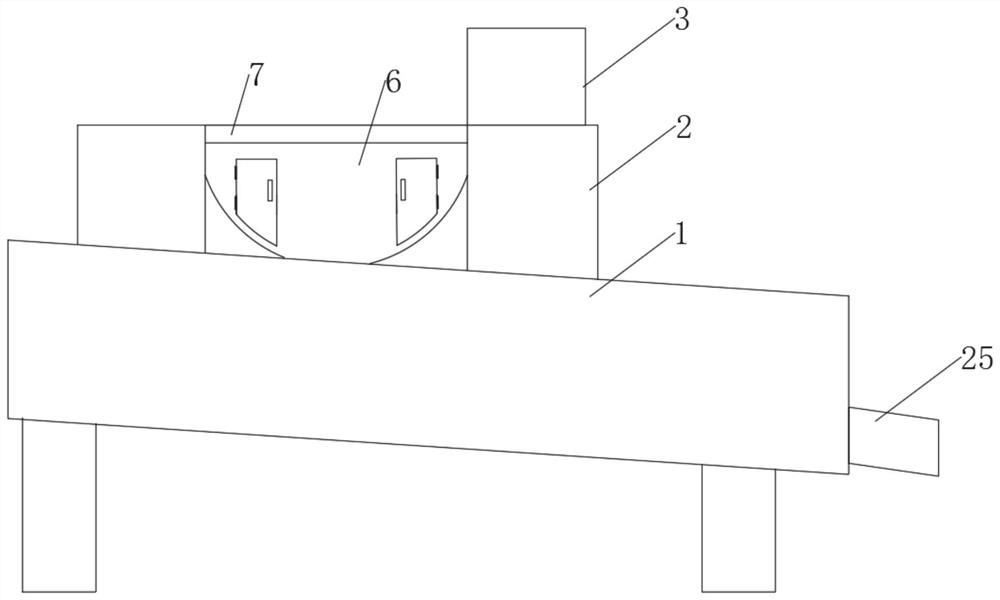

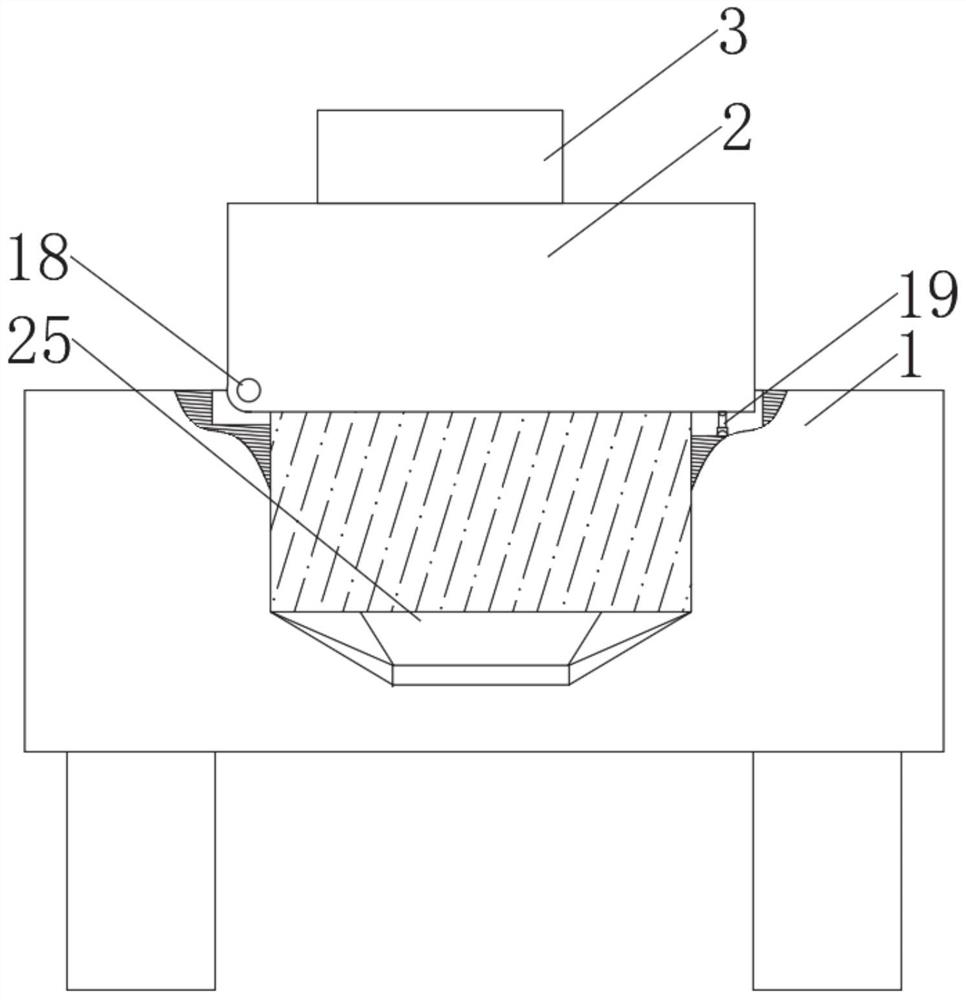

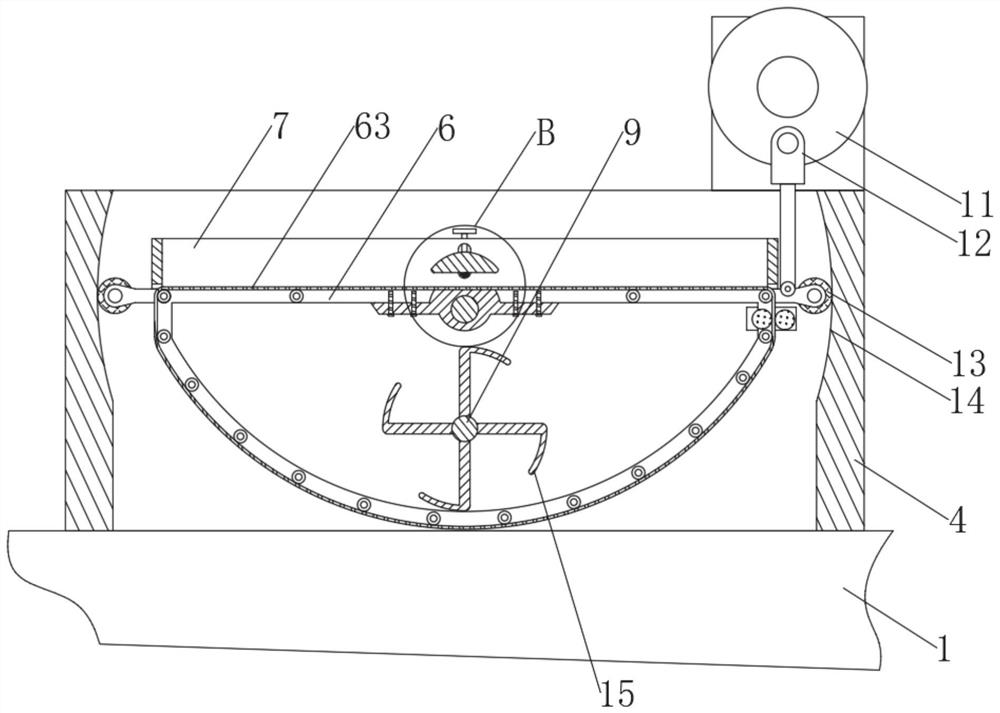

[0035] The present invention provides such as Figure 1-10 The vibrating source top-mounted environment-friendly old asphalt screening machine shown includes a material rack 1, a screening frame 2 and a vibrating frame 3, and the material rack 1 and the vibrating frame 3 are respectively arranged at the bottom and top of the screening frame 2 , the upper surface of the material rack 1 is provided with a chute, the screening frame 2 includes a C-shaped frame 4, the inner wall of one side of the C-shaped frame 4 is rotatably connected to a rotating shaft, and the outer side of the rotating shaft is fixedly connected to an installation connecting plate 5. The inside of the C-shaped frame 4 is provided with a swing frame 6, and the swing frame 6 is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com