Needle bed device of flat knitting machine and flat knitting machine

A technology of flat knitting machines and needle beds, which is applied in knitting, weft knitting, textiles and papermaking, etc. It can solve the problems of difficulty in meeting the shape and position tolerance requirements of the machine head, increasing the width of the flat knitting machine, and increasing the difficulty of the needle selection mechanism and other issues to achieve the effect of compact structure, simplified structure and easy assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

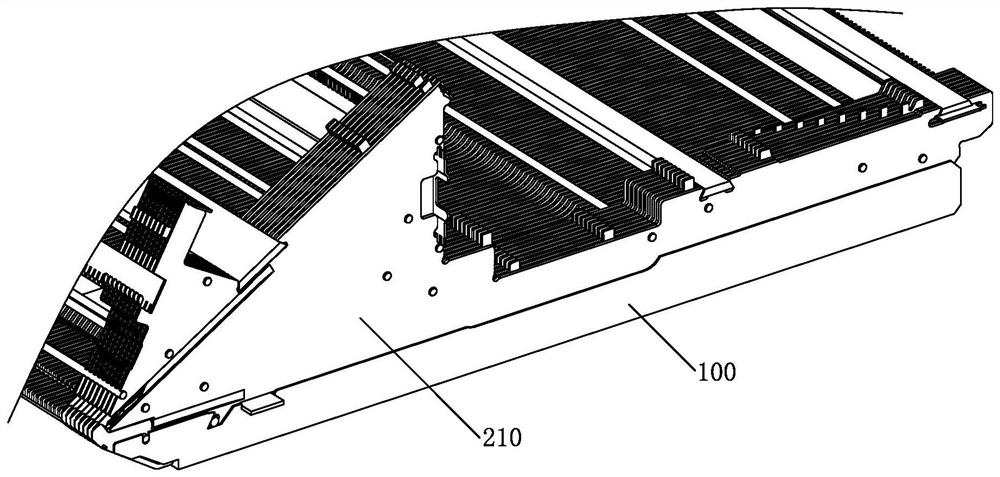

[0044] Such as Figure 1 to Figure 8 As shown, the needle bed device of a flat knitting machine provided by Embodiment 1 of the present invention includes a needle bed 100 and inserting pieces 210 arranged on the needle bed 100. The inserting pieces 210 are arranged in parallel and at intervals along the length direction of the needle bed 100. There are multiple needle slots formed between the adjacent inserts 210, and the lower knitting needles 310 and the lower jacking pins 320 arranged in front and back are arranged in the needle slots. Between the lower knitting needle 310 and the lower jerk pin 320 is provided with a turnable conversion stitch 410, and a partition 220 positioned at the top of the lower knitting needle 310 is also provided in the needle groove, and the top of the partition 220 is provided with The upper knitting needle 510 that is arranged obliquely at 310, the rear end of the upper knitting needle 510 is connected with an upper stitch 520 that can swing u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com