Carbon nanotube composite catalytic membrane and preparation method thereof

A technology of carbon nanotube composite and carbon nanotube film, which is applied in the direction of chemical instruments and methods, nanotechnology, carbon compounds, etc., can solve the problems of scarcity application restrictions, high cost, etc., and achieve good catalytic performance, low cost, and source wide effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] See figure 1 , the invention provides a kind of preparation method of carbon nanotube composite catalytic membrane, it comprises the following steps:

[0028] S1, providing a carbon nanotube film;

[0029] S2, provide a precursor solution, this precursor solution contains Fe(NO 3 ) 3 (ferric nitrate), NiCl 2 (nickel chloride) and MoCl 5 (molybdenum pentachloride);

[0030] S3, disposing the precursor solution on the carbon nanotube film, and obtaining a precursor film after drying;

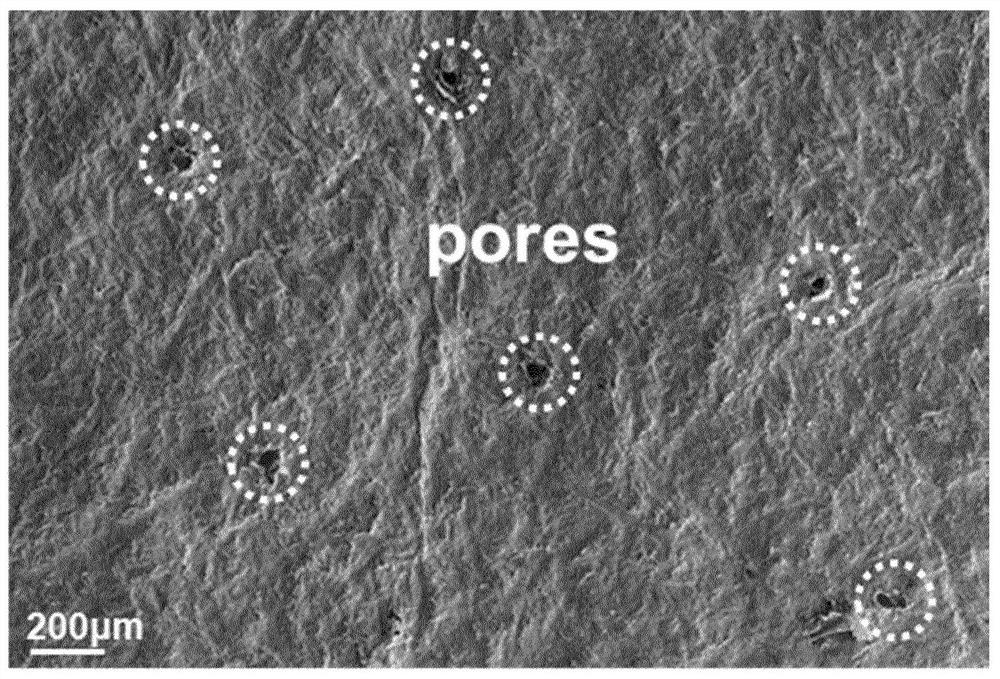

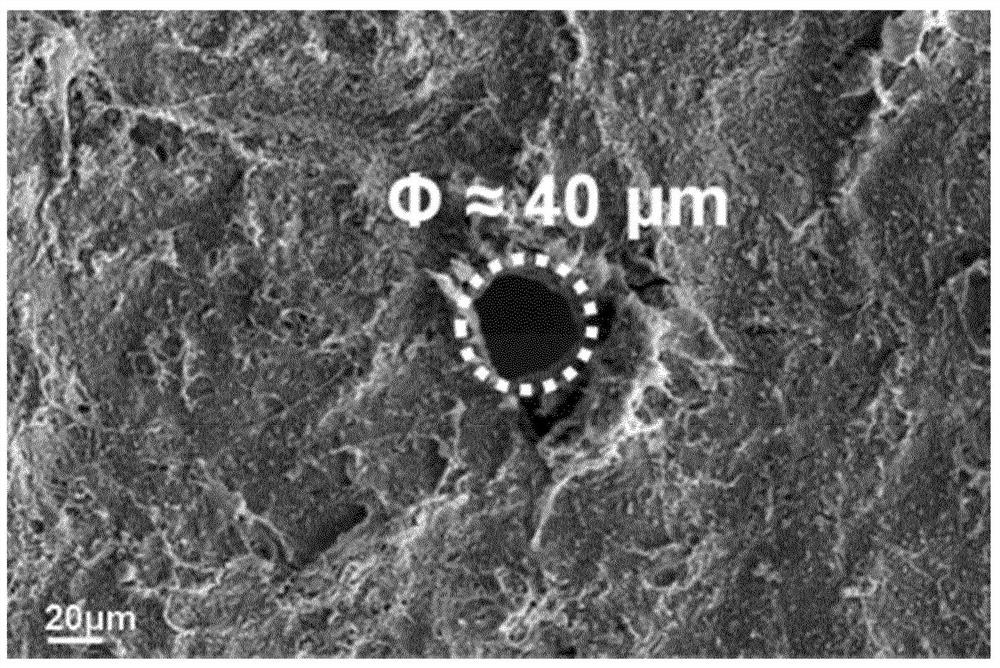

[0031] S4, setting a plurality of holes arranged at intervals on the precursor film; and

[0032] S5, annealing the precursor film with multiple pores, and adding sulfur powder during the annealing process to obtain a carbon nanotube composite catalytic film.

[0033] In step S1, the preparation method of the carbon nanotube film comprises the following steps:

[0034] S11, providing a carbon nanotube raw material;

[0035] S12, adding the carbon nanotube raw material into a solven...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com