Coconut shell and flesh separator

A separator, coconut shell technology, applied in application, food science, food processing and other directions, can solve the problems of restricting the development of coconut processing enterprises, unsatisfactory coconut meat harvesting efficiency, easy to cause industrial accidents, etc., and achieves easy mechanized peeling. The effect of processing, meeting food hygiene requirements, and reducing personal injury and disability accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

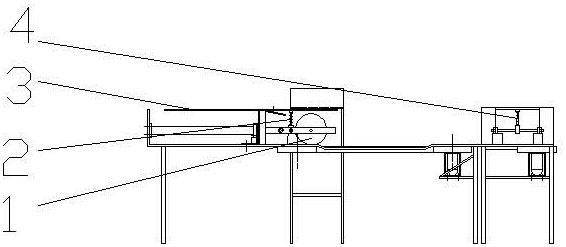

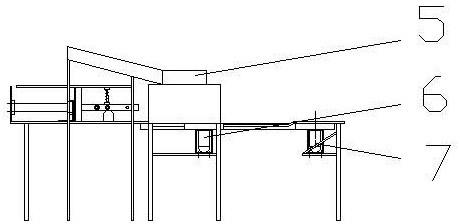

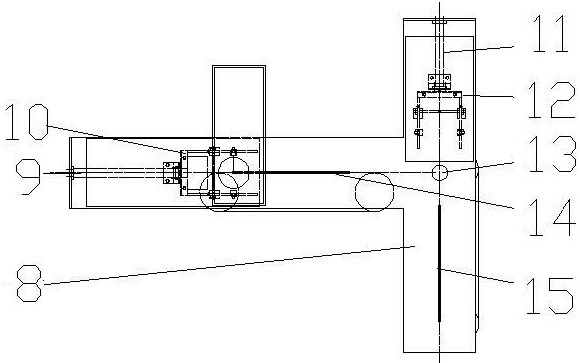

[0011] Be provided with frame, be provided with workbench 8 on the frame, be provided with transverse cutting device and longitudinal cutting device on workbench 8, described transverse cutting device is provided with transverse electric push rod 9, and the front portion of transverse electric push rod 9 is provided with Horizontal manipulator 10 is arranged, and the top of transverse manipulator 10 is provided with transverse compression spring 2, and the top of transverse compression spring 2 is provided with feeding device 5, and the bottom of feeding device 5 is provided with baffle plate 3, and the front of transverse manipulator 10 is provided with There is a horizontal cutting band saw 14, the front of the horizontal cutting band saw 14 is provided with a positioning hole 13, the longitudinal cutting device is provided with a longitudinal electric push rod 11, and the front part of the longitudinal electric push rod 11 is provided with a longitudinal manipulator 12, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com