Self-adaptive forage grass filament rubbing machine and control method

An adaptive and forage technology, applied in applications, agricultural machinery and tools, cutting equipment, etc., can solve problems such as poor forage rubbing effect, inconsistent rubbing effect, and inaccurate control of forage quantity, so as to achieve stable and uniform rubbing quality , Precisely control the kneading effect, the effect of small friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

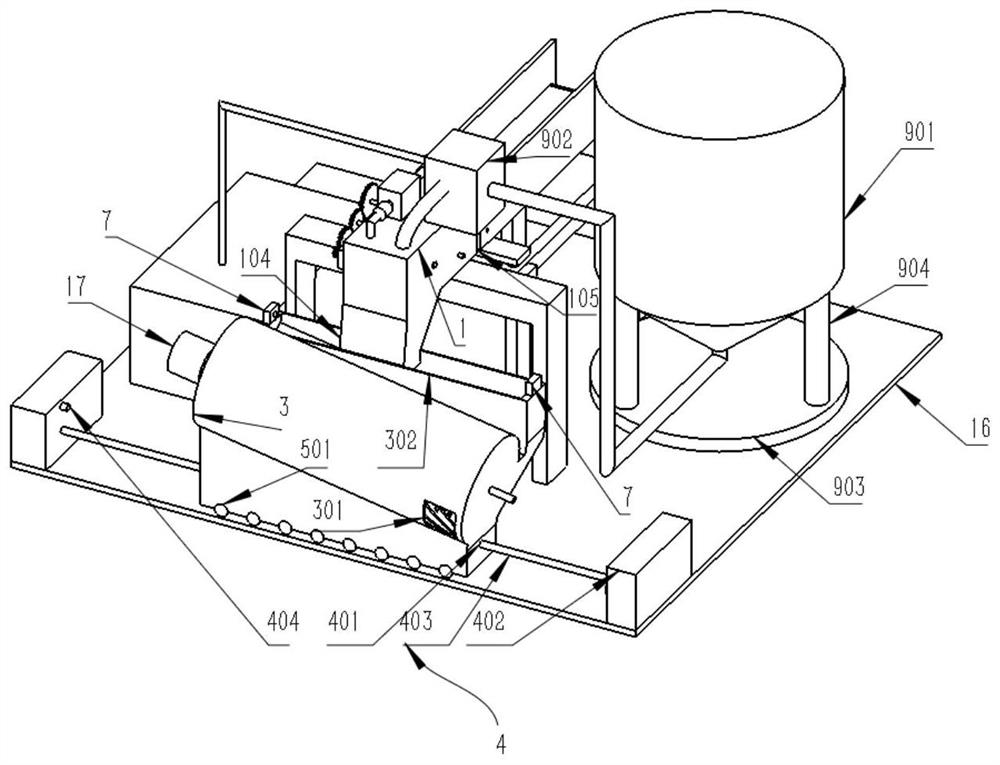

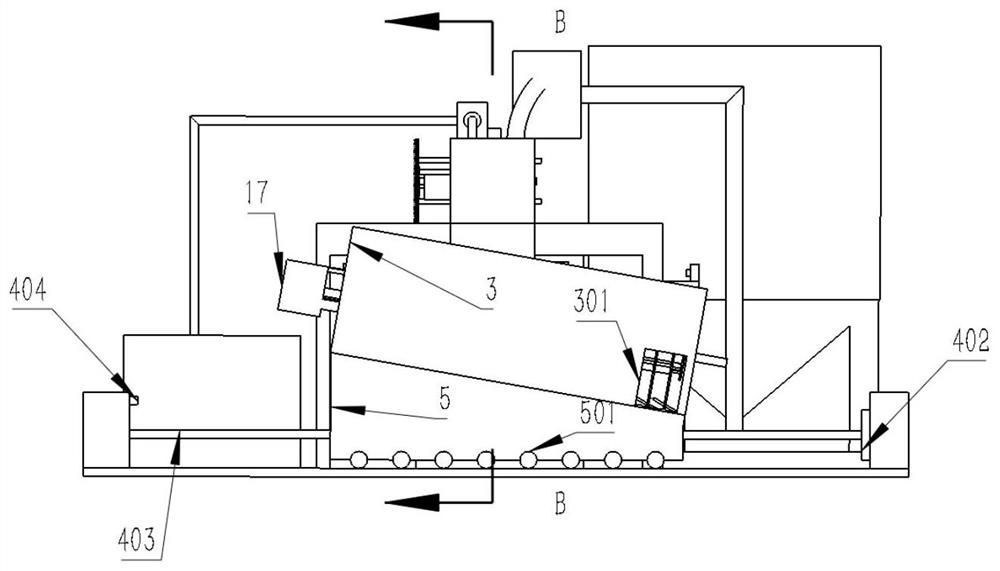

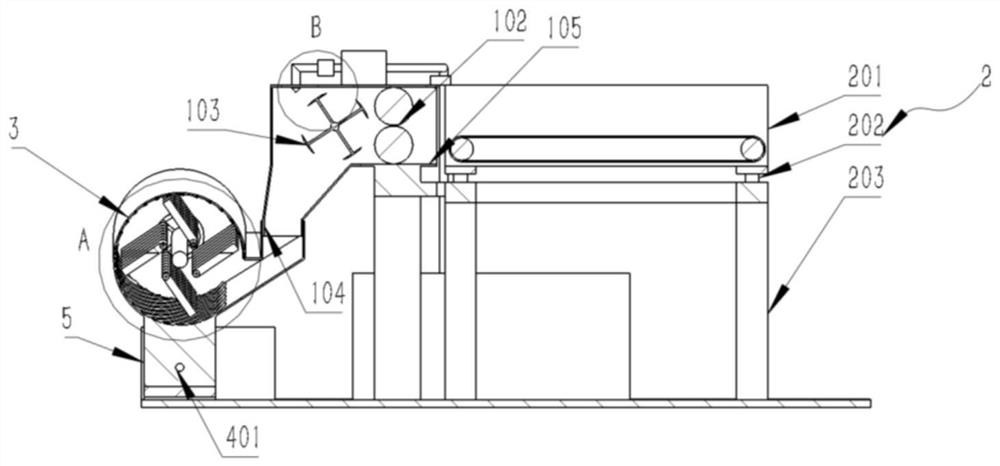

[0074] Implementation Example 1: In this embodiment, an adaptive pasture kneading machine includes: a first motor 101; a side grass device 1, the side grass hob 103 of the side grass device 1 is connected to the first motor 101; a feed roller 102, the feed roller 102 is arranged between the feed port 105 of the side grass device and the side grass hob 103, the feed roller 102 is connected with the first motor 101; it also includes: a controller 15; a bottom plate 16, the Said side grass device 1 is bolted or welded on the base plate 16; weighing device 2, said weighing device 2 communicates with side grass device inlet 105, and weighing device 2 is placed on the base plate 16, and weighing device 2 Connect with controller 15 lead wires; Knead silk cylinder 3, described knead silk cylinder 3 is cylindrical, knead silk cylinder 3 rear portion sidewalls and have kneading silk cylinder feed opening 302 along kneading silk cylinder 3 lengthwise directions, side The outlet 104 of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com