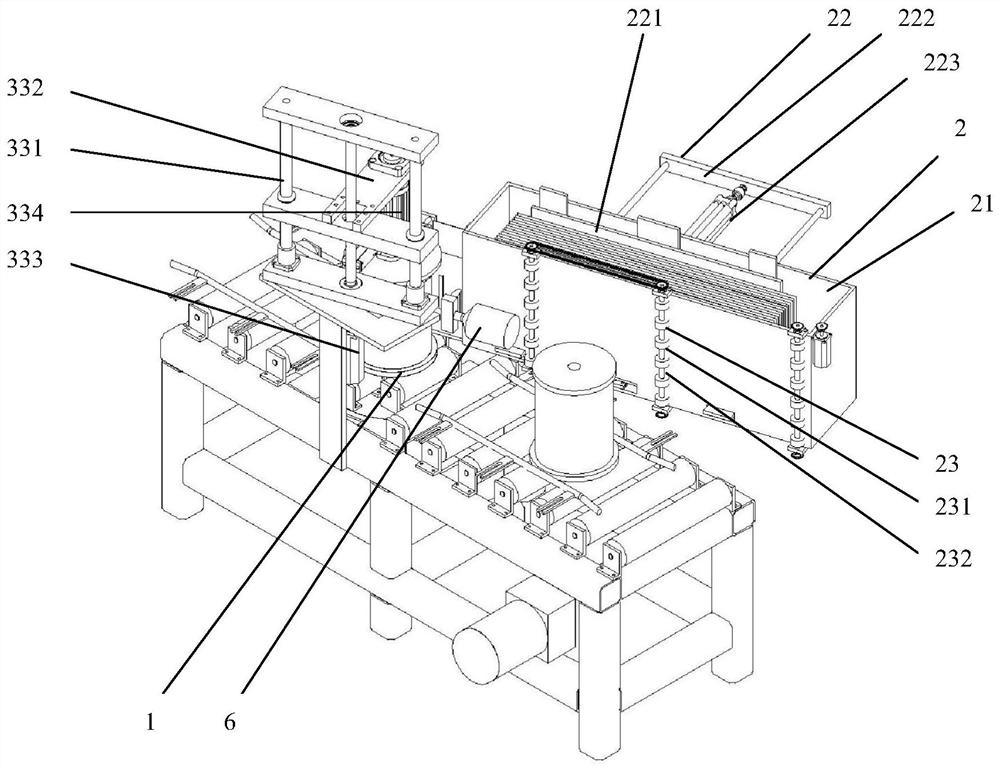

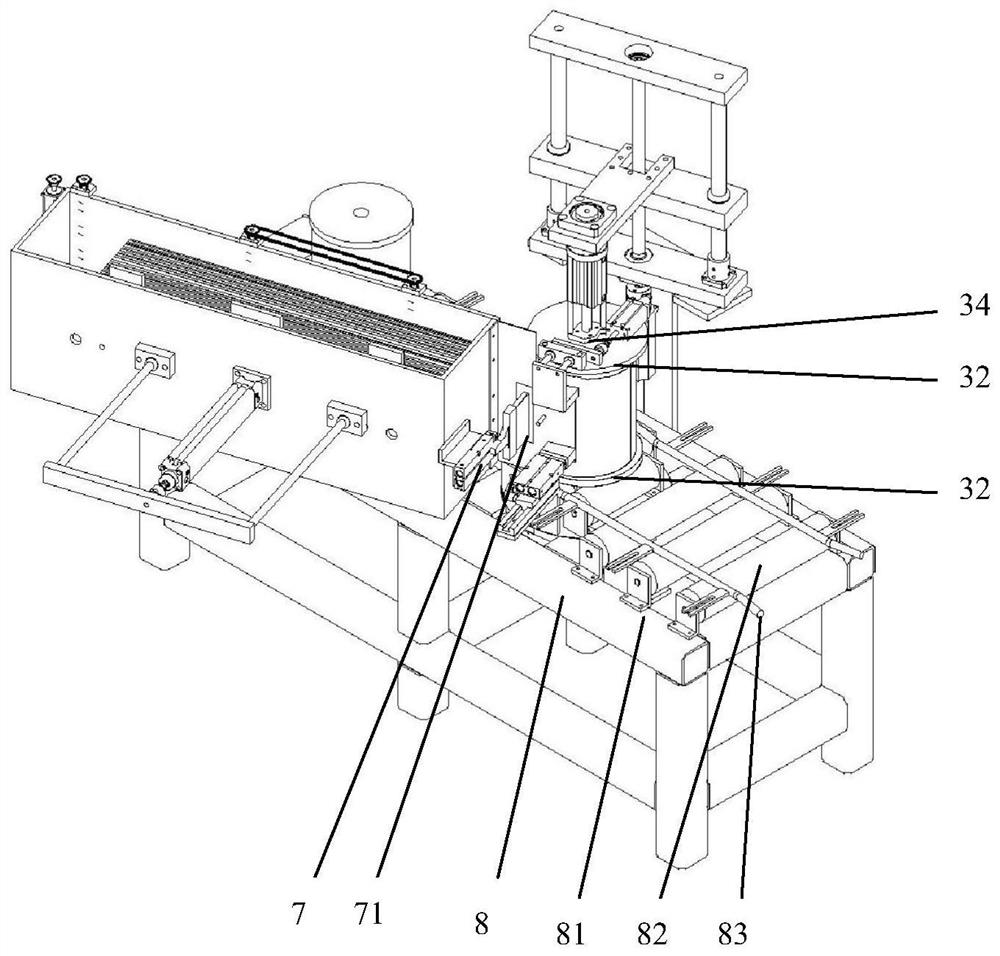

Wrapping paper packaging equipment and method

A technology of packaging equipment and wrapping paper, applied in the field of wrapping wrapping equipment, can solve the problems of positioning and packaging of reels that cannot be placed vertically, and achieve the effect of avoiding the use of multiple stacks, ensuring stability, and accurate automatic wrapping performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0111] In a further embodiment of the present invention, a method for wrapping paper packaging equipment is also provided, including:

[0112] Step S1: The positioning mechanism 3 positions the upper part and / or the lower part of the packaged object;

[0113] Step S2: the separation mechanism 2 separates and outputs the packaging material along the tangential direction of the packaged body, so that one end of the packaging material is output to the tangent point of the packaged body;

[0114] Step S3: the clamping mechanism 5 makes one end of the packaging material stick to the packaged body;

[0115] Step S4: The driving mechanism 4 drives the packaged body to rotate around the axis of the packaged body, and the clamping mechanism 5 rotates synchronously with the packaged body, so that the packaging material is wound on the packaged body;

[0116] Step S5: The drive mechanism 4 is further driven until the other end of the packaging material is about to break away from the se...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap