Bearing ring outer wall machining precision detection device

A technology for bearing rings and processing accuracy, which is applied to measuring devices, devices for coating liquid on the surface, instruments, etc., can solve the problems of bearing rings coated with anti-rust oil, low detection efficiency, etc., and achieves simple structure, Convenient operation and improved detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

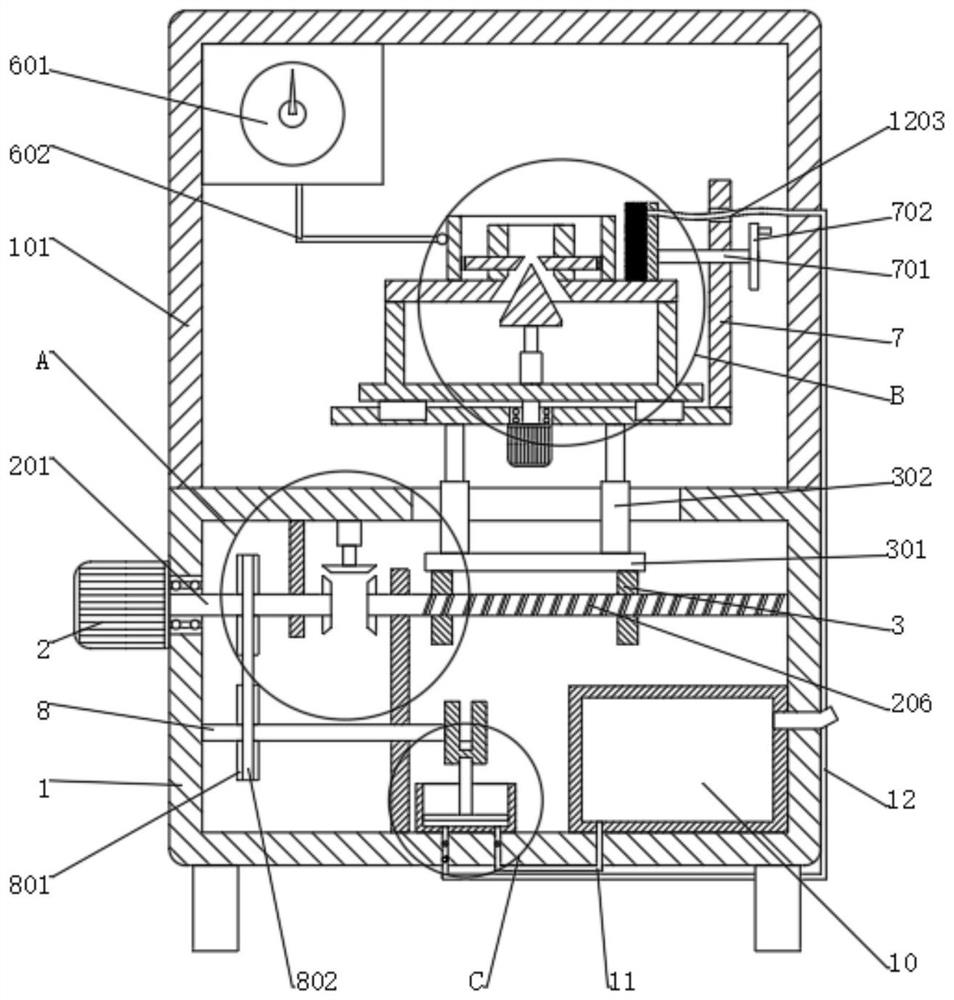

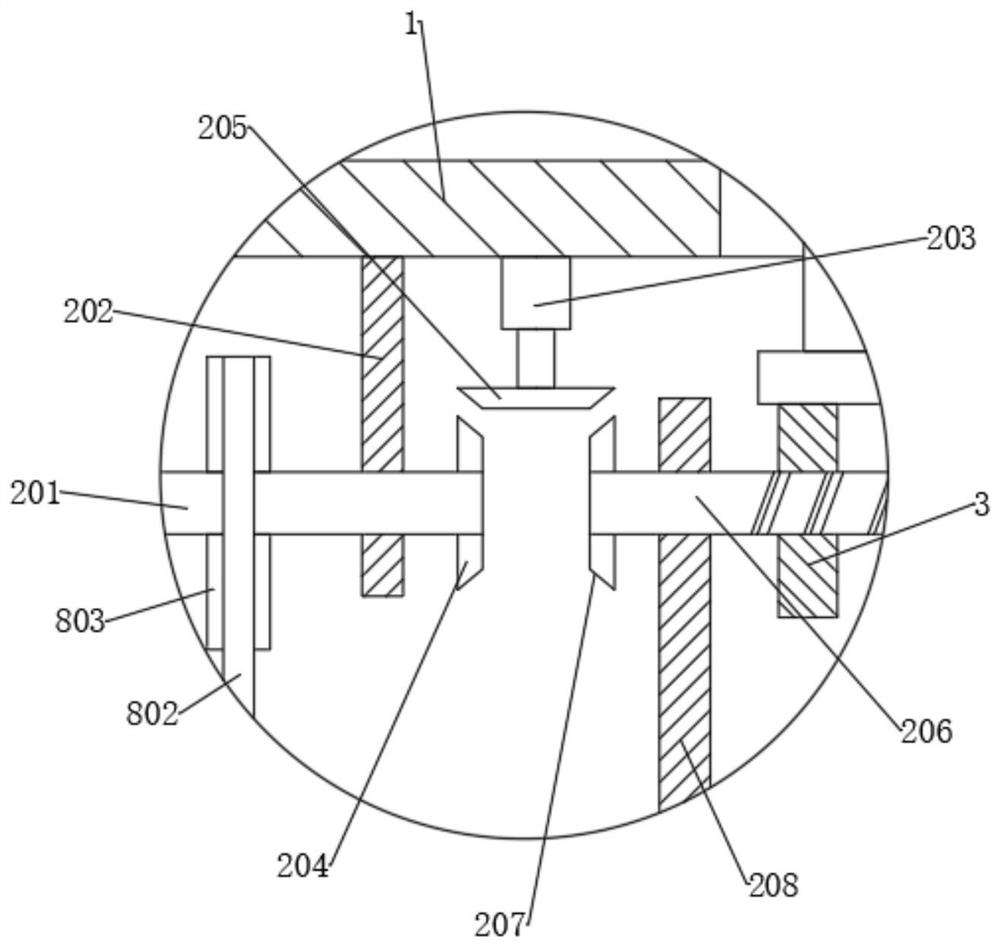

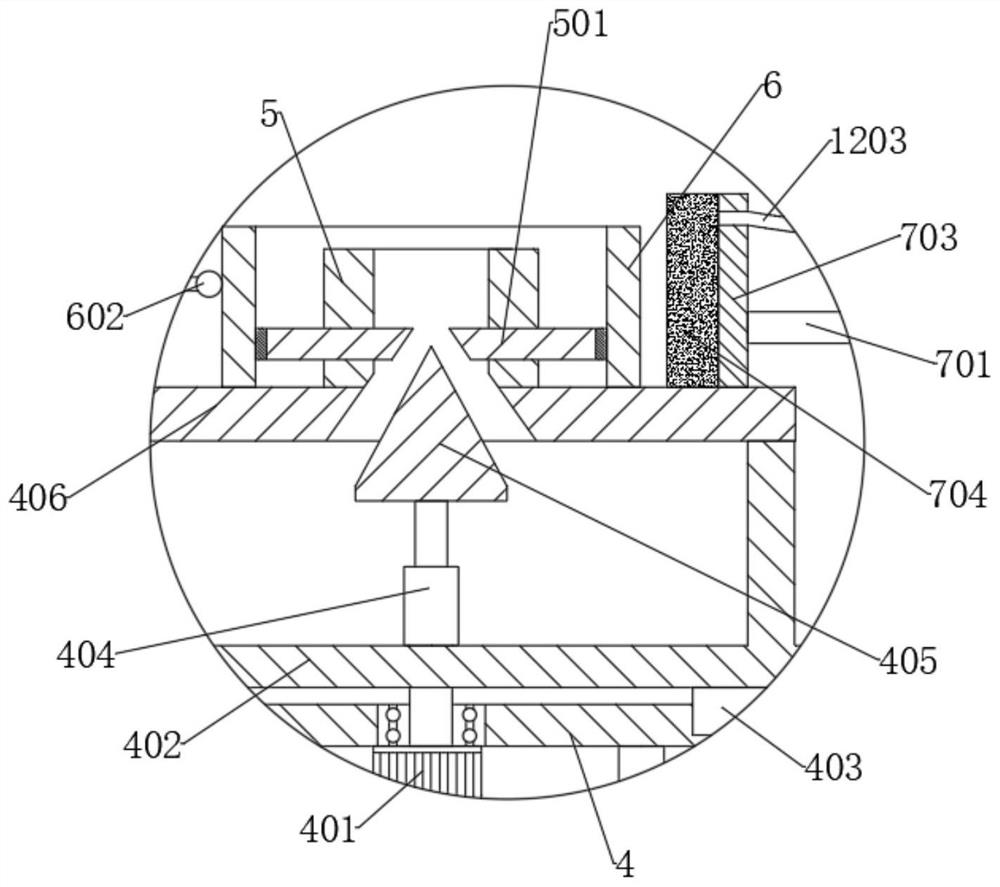

[0029] refer to Figure 1-6 , a bearing ring outer wall processing accuracy detection device, including a box 1, a support cover 101 and a bearing ring body 6, the support cover 101 is fixedly connected to the top of the box body 1, and the side wall of the box body 1 is provided with a first motor 2, The output end of the first motor 2 is connected with the first rotating shaft 201, and the inner wall of the box body 1 is also respectively connected with the first threaded rod 206 and the second rotating shaft 8, and the first rotating shaft 201 and the first threaded rod 206 are connected with the first rotating shaft 201. Transmission mechanism, the first threaded rod 206 is threadedly connected with a threaded block 3, the threaded block 3 is fixedly connected with a first moving plate 301, the first moving plate 301 is provided with a lifting mechanism, and the lifting mechanism is rotatably connected with a concave plate 402, A workbench 406 is fixedly connected to the c...

Embodiment 2

[0041] refer to Figure 1-6 , a bearing ring outer wall processing accuracy detection device, including a box 1, a support cover 101 and a bearing ring body 6, the support cover 101 is fixedly connected to the top of the box body 1, and the side wall of the box body 1 is provided with a first motor 2, The output end of the first motor 2 is connected with the first rotating shaft 201, and the inner wall of the box body 1 is also respectively connected with the first threaded rod 206 and the second rotating shaft 8, and the first rotating shaft 201 and the first threaded rod 206 are connected with the first rotating shaft 201. Transmission mechanism, the first threaded rod 206 is threadedly connected with a threaded block 3, the threaded block 3 is fixedly connected with a first moving plate 301, the first moving plate 301 is provided with a lifting mechanism, and the lifting mechanism is rotatably connected with a concave plate 402, A workbench 406 is fixedly connected to the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com