Telescopic cabinet lock

A technology for telescopic machines and cabinet locks, which is applied in the direction of mechanical equipment, thin plate connections, connecting components, etc., can solve problems such as complex structures, and achieve the effect of simple and reliable locking and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

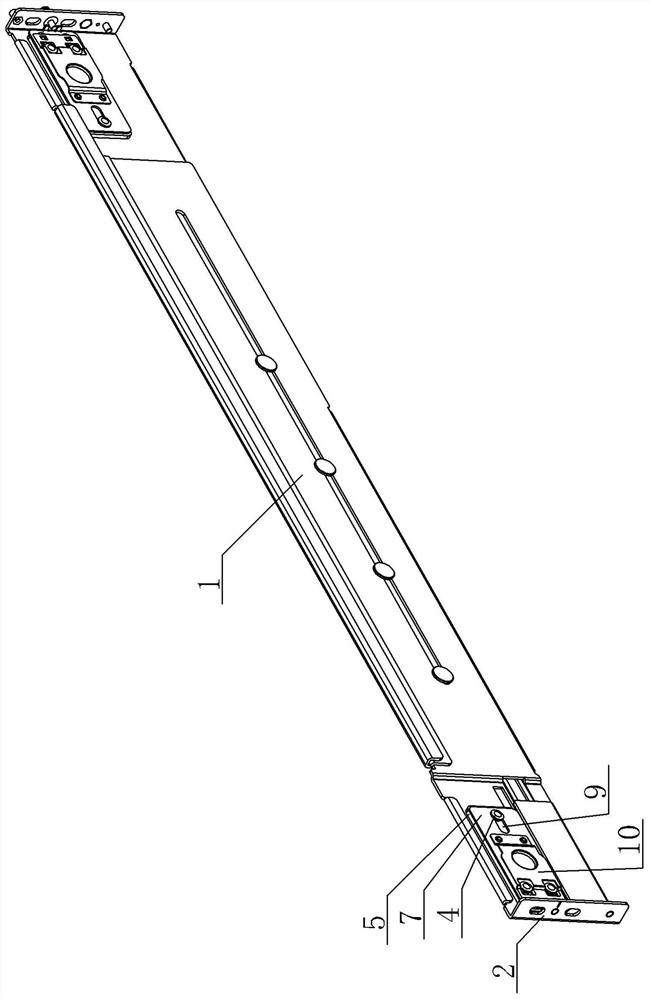

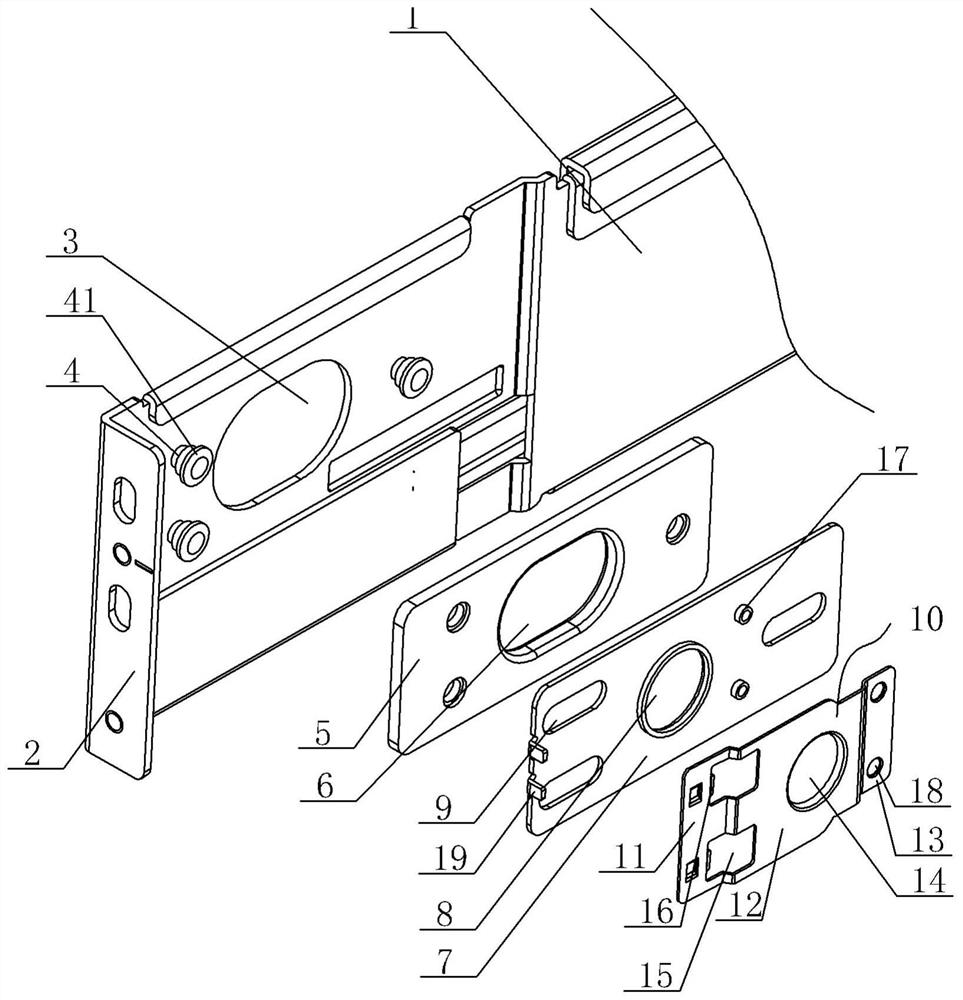

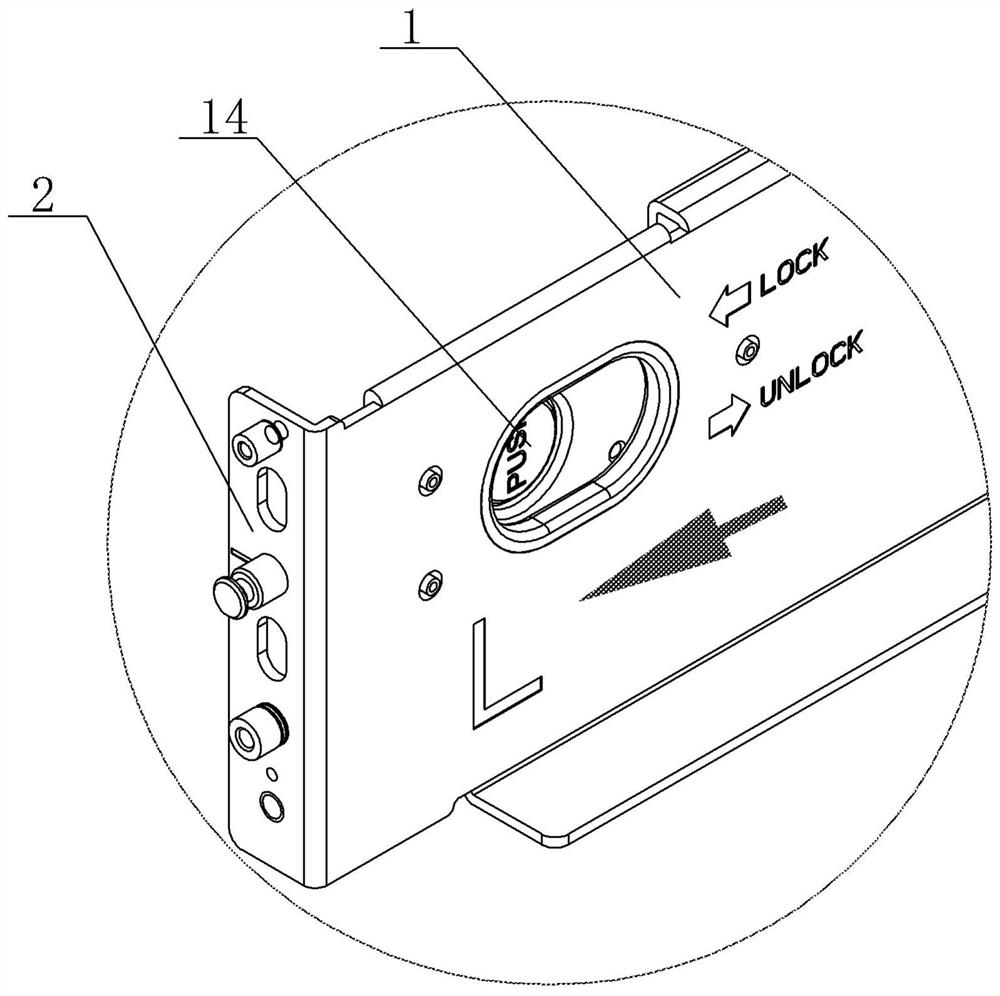

[0018] A retractable cabinet lock, see Figure 1-Figure 4 : It includes a strip-shaped guide rail bracket 1, the two ends of the length direction of the guide rail bracket 1 are respectively provided with bending ribs 2, and the inner side area of the guide rail bracket 1 opposite to the bending flange 2 is provided with a corresponding long groove guide Hole 3, the back side of the area area of long slot guide hole 3 is fixedly equipped with the first connecting plate 5 by the end step rivets 4 at both ends, and the area corresponding to the long slot guiding hole 3 of the first connecting plate 5 is provided with the first connecting plate 5. Two long slot holes 6, the second long slot hole 6 is overlapped with the long slot guide hole 3, and the back side of the first connecting plate 5 is provided with a guide slide 7, and the guide slide 7 is respectively installed on the first step through the end step rivet 4. A connecting plate 5, the guide slide 7 is provided with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com