Wide roll loading and unloading mechanism, splitting machine equipment and using method of splitting machine equipment

A technology of loading and unloading mechanism and slitting machine, which is applied in the direction of winding strips, thin material handling, transportation and packaging, etc., can solve the problems of restricting the production efficiency of slitting machine, inability to install wide-width roll materials, and labor intensity of workers. , to achieve the effect of convenient coring and installation of wide coiling process, omitting manual operation and reducing standby time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

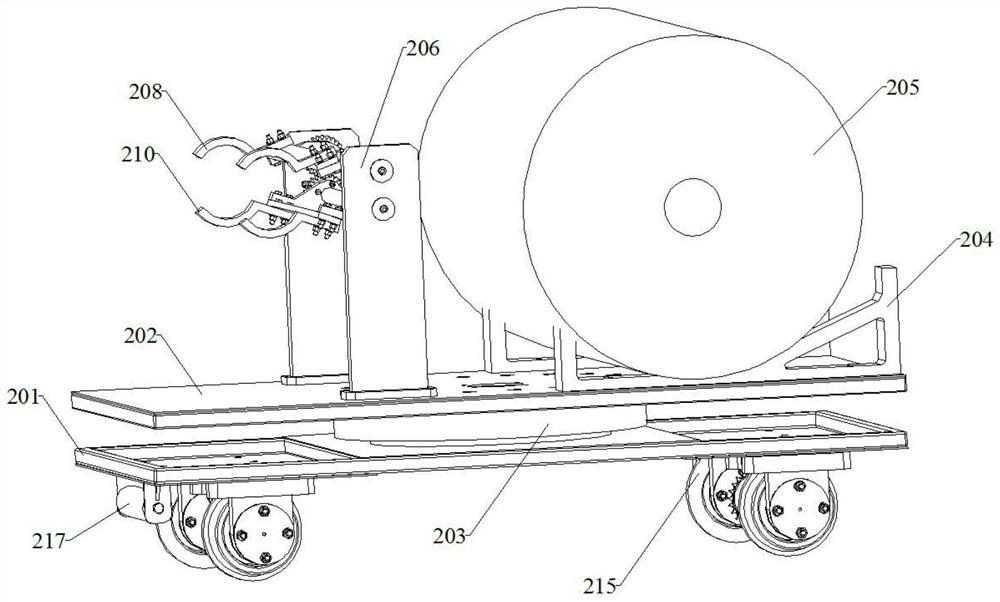

[0053] Such as Figure 1-Figure 5 As shown, the wide-width coil loading and unloading mechanism of this embodiment includes a movable chassis 201, a turntable 202, and a rotating assembly 203 for driving the turntable 202 to rotate on the movable chassis 201. The turntable 202 passes through the rotating assembly 203 and the movable chassis. 201 is connected, and the turntable 202 is provided with a wide-width coil material unwinding seat 204 and a core-taking assembly for removing the core of the wide-width coil material 205 .

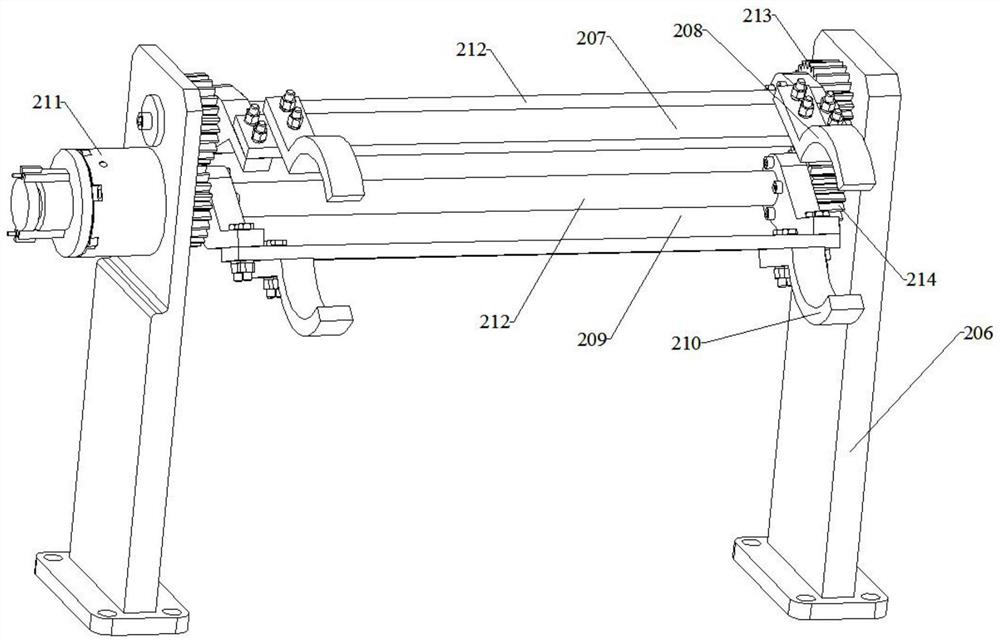

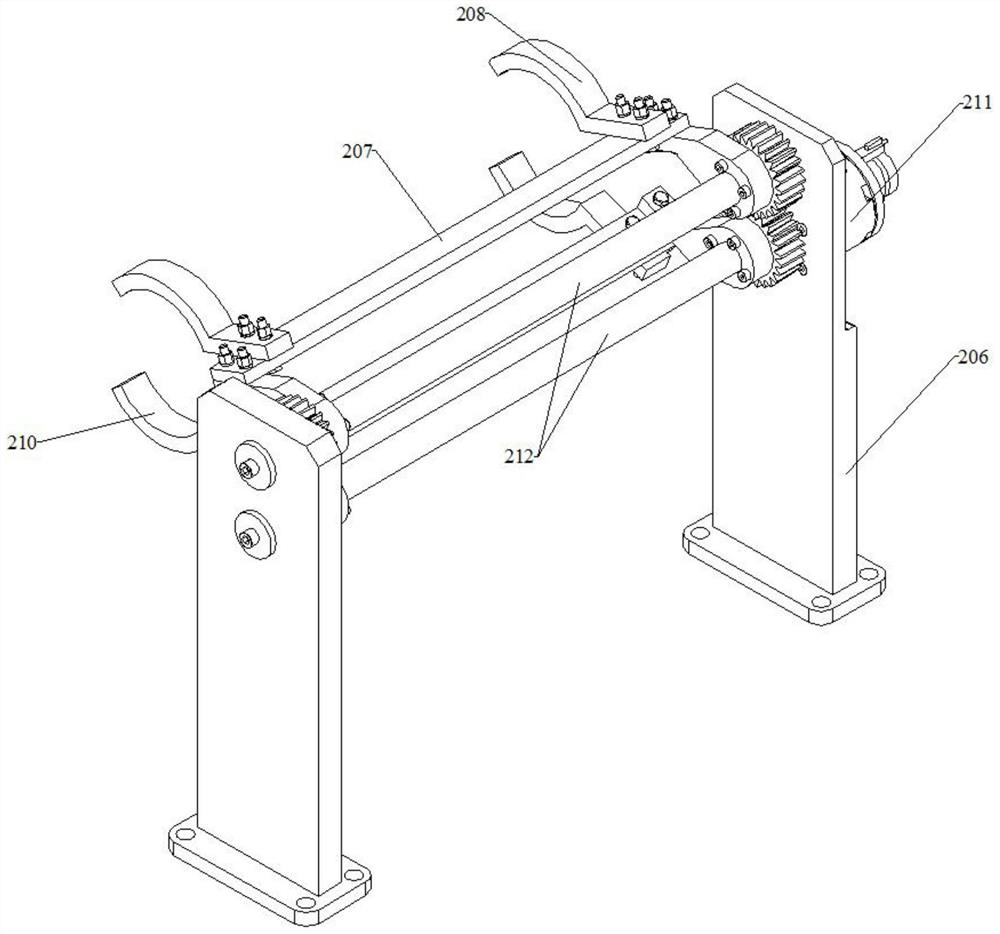

[0054] Such as Figure 2-Figure 3 As shown, in this embodiment, the coring assembly includes a support 206, a manipulator and a manipulator driving source for driving the manipulator to clamp or loosen. The manipulator is installed on the turntable 202 through the support 206, and the manipulator is used to grab a wide As for the winding core of the coil material 205, the diameter D of the empty winding core is 75 mm, and the length L is 800 mm. Spe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com