A pressure sensing electromechanical pressure detection device

An air pressure detection and sensing technology, which is applied in the direction of measuring devices, measuring fluid pressure, instruments, etc., can solve the problem of low measurement accuracy, achieve centralized and accurate measurement results, and avoid the effect of excessive local pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

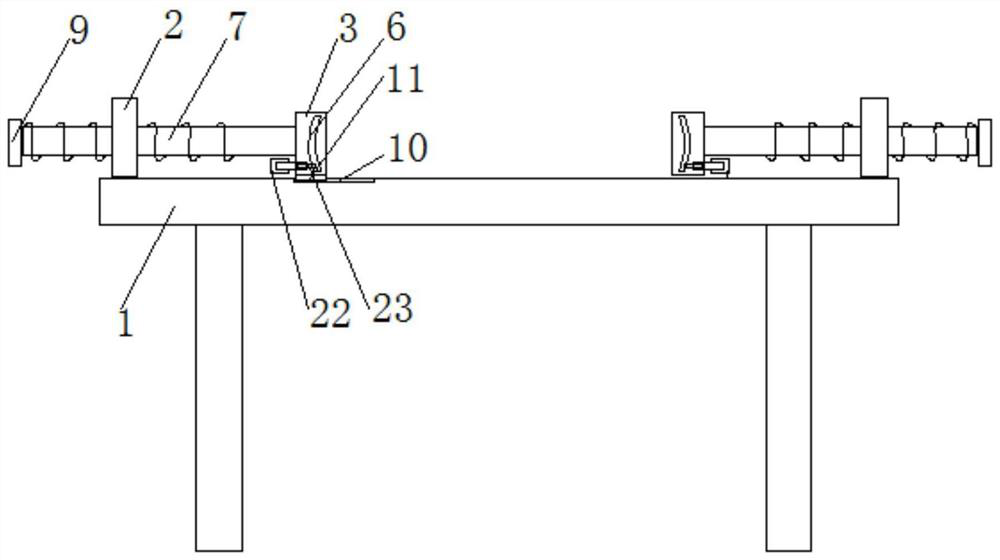

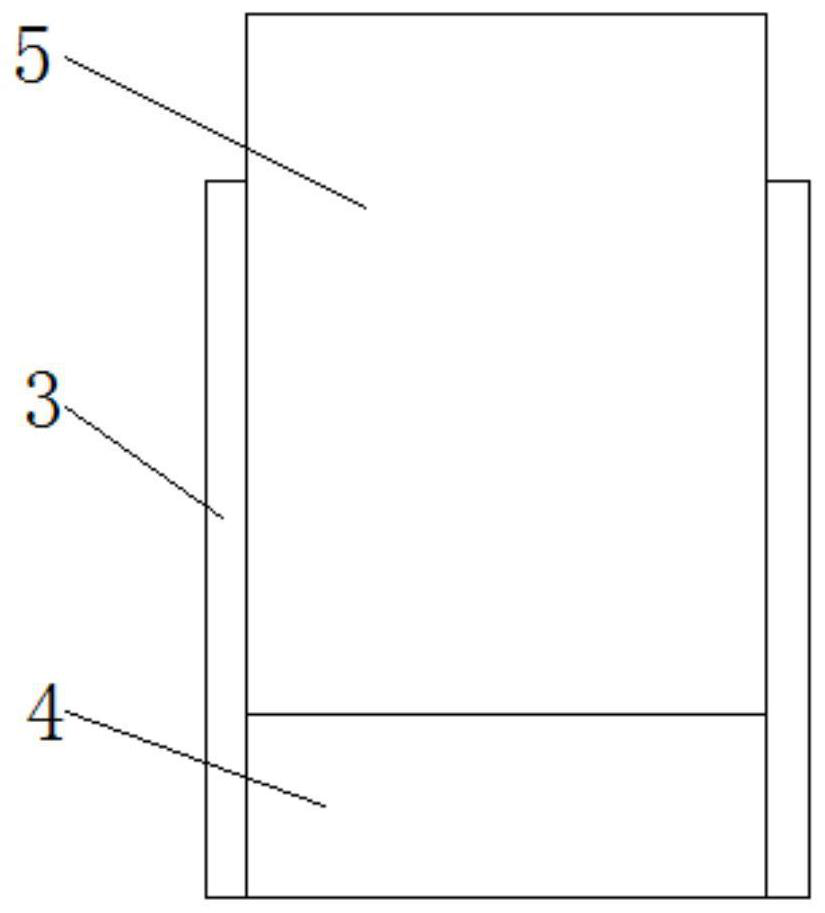

[0029] A pressure sensing type electromechanical pressure detection device, such as Figure 1-3 As shown, it includes an operating table 1, which is used to place fixtures and workpieces to be measured; it also includes a fixed block 2 arranged on the surface of the operating table 1, and two fixed blocks 2 are provided, and the two fixed blocks 2 are respectively fixed on the On both sides of the surface of the console 1, the side of the fixed block 2 is provided with threaded holes, and also includes a rectangular detection clip 3. There are two rectangular detection clips 3, which are respectively arranged between the two fixed blocks 2. The rectangular detection clip 3 is Hollow rectangular block, two rectangular detection clips 3 are respectively provided with notches 4 on the opposite sides, the notches 4 are provided with push-pull baffles 5, the push-pull baffles 5 are movably connected with both sides of the notch 4, and the push-pull baffles 5 can be Vertically stret...

Embodiment 2

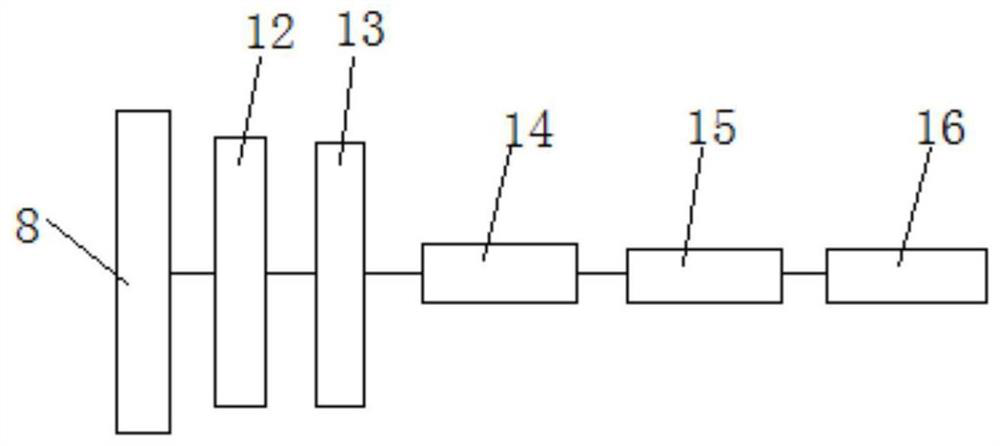

[0034] Further, on the basis of embodiment 1, such as Figure 4 As shown, the push-out mechanism includes a push-out rod 23 arranged horizontally, one end of the push-out rod 23 is fixedly connected with the arc-shaped detection clip 6, and the other end of the push-out rod 23 passes through the side wall of the rectangular detection clip 3 and is threadedly connected with a screw rod 17. It also includes a hollow fixed rod 18, the screw rod 17 is inserted into the hollow fixed rod 18, the end of the screw rod 17 is also sleeved with a first bevel gear 19, and the hollow fixed rod 18 is provided with a first bevel gear 19 meshing with the first bevel gear. Two bevel gears 20, the outer wall of the hollow fixed rod 18 is also provided with a rotary handle 21, and the rotary handle 21 passes through the side wall of the hollow fixed rod 18 and is connected with the second bevel gear 20; Groove 25, the both sides of screw mandrel 17 are provided with retractable stop rod 24, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com