Energy-saving glass curtain wall with cleaning device

An energy-saving glass and cleaning device technology, applied to walls, cleaning equipment, household appliances, etc., can solve the problems of bacterial growth, inability to clean bacteria, and affect the light transmission effect of glass curtain walls, etc., and achieve the effect of simple and convenient operation and good cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The following is attached Figure 1-6 The application is described in further detail.

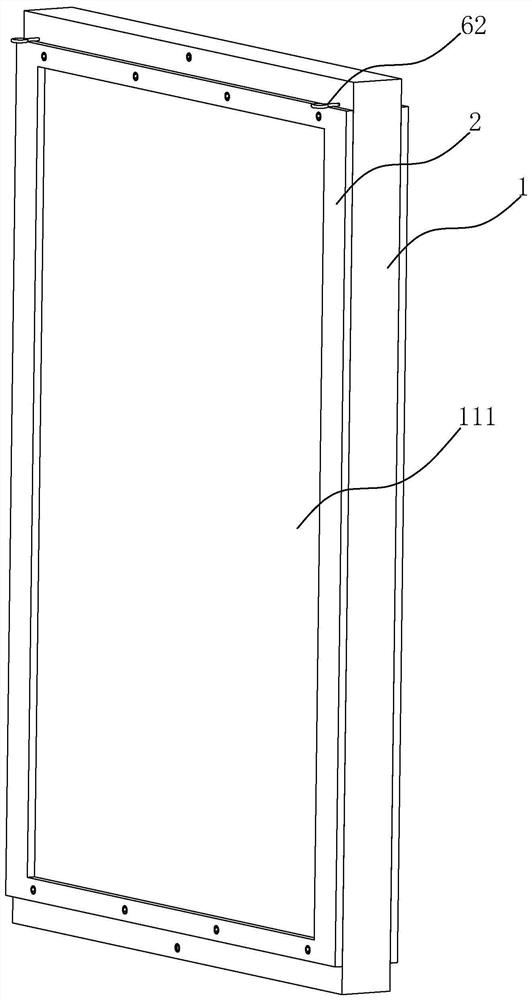

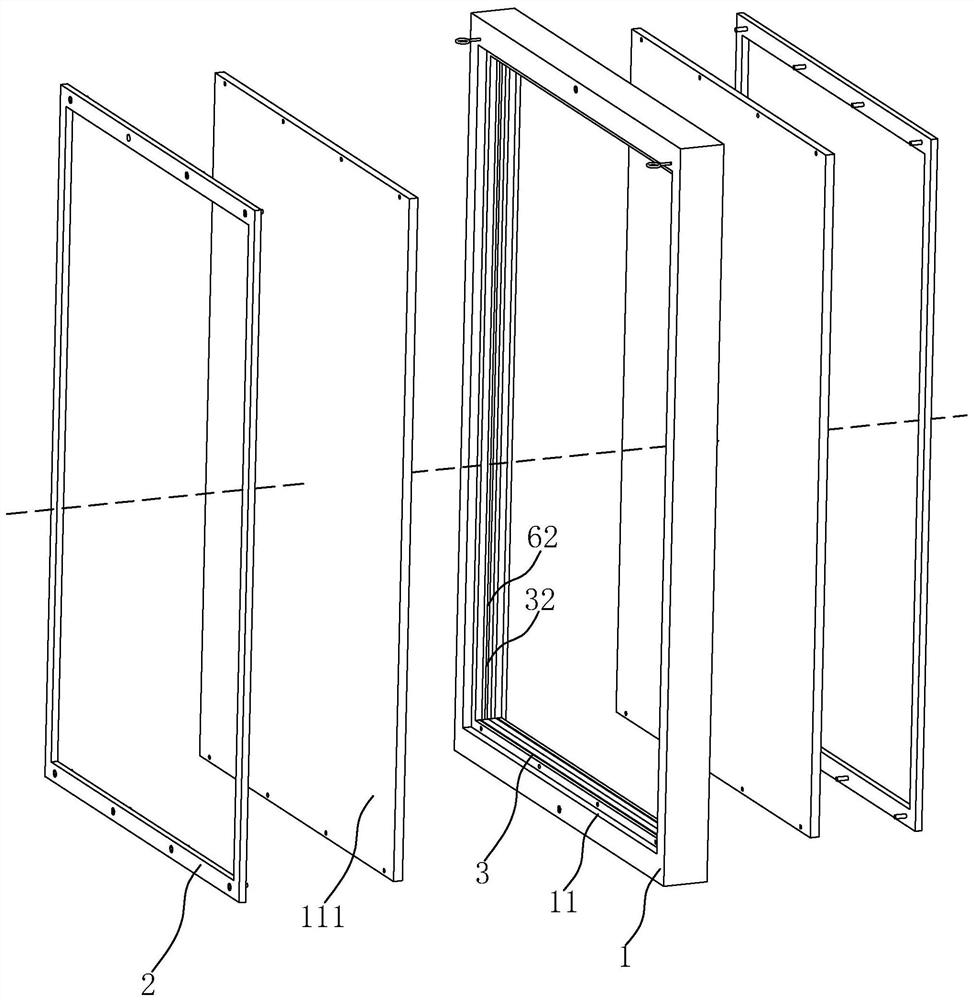

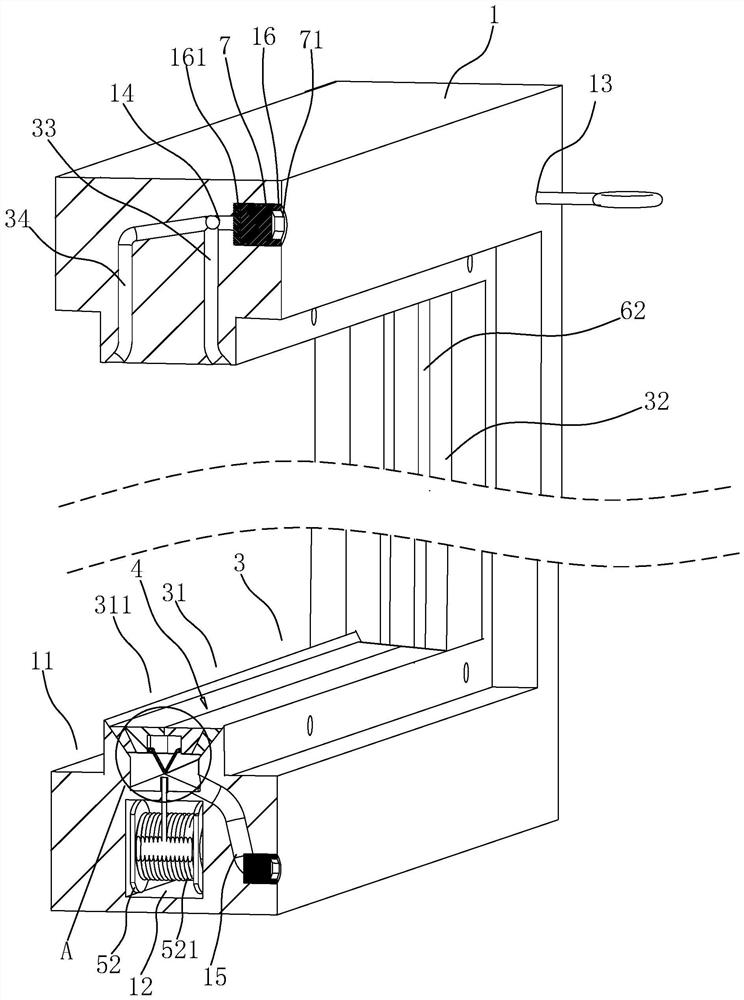

[0035] The embodiment of the application discloses an energy-saving glass curtain wall with a cleaning device. refer to figure 1 , figure 2 The curtain wall includes a rectangular support frame 1 fixed on the wall. Both sides of the support frame 1 are provided with a rectangular assembly groove 11. The assembly groove 11 is embedded with a glass plate 111. The glass plate 111 is away from the assembly groove 11. One side of the bottom wall is flush with the side wall of the support frame 1, and the side wall of the glass plate 111 away from the bottom wall of the assembly groove 11 is provided with an annular cover plate 2, and a plurality of fixing bolts are pierced on the cover plate 2, and the fixing bolts pass through The cover plate 2 and the glass plate 111 are installed on the bottom wall of the assembly groove 11, and then the cover plate 2 and the glass plate 111 are fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com