Coiled material ironing roller device of high-speed cold-rolling mill

A technology for ironing rolls and cold rolling mills is applied in the field of aluminum sheet processing to achieve the effect of simplifying the constant pressure control system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Preferred embodiments of the present invention are described below with reference to the accompanying drawings. Those skilled in the art should understand that these embodiments are only used to explain the technical principles of the present invention, and are not intended to limit the protection scope of the present invention.

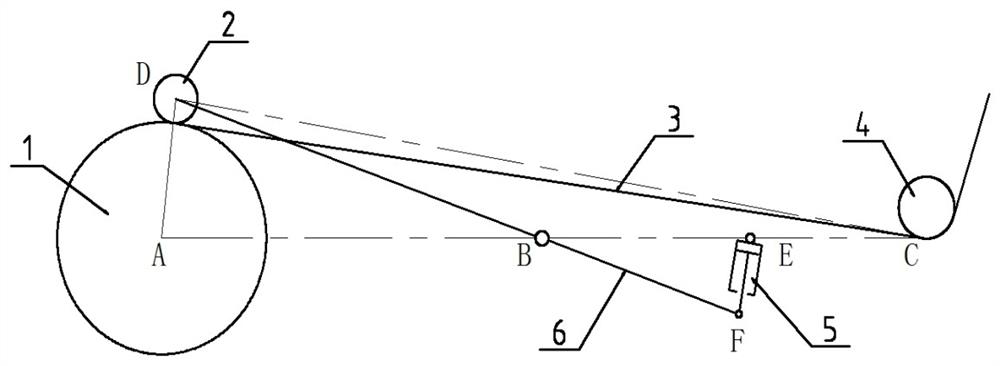

[0015] A high-speed cold rolling mill coil ironing roll device, such as Figure 1-2 As shown, the coiled material 3 is wound up on the winding roller 1 after being tightened by the angle-wrapping roller 4, and the ironing roller 2 is installed on one end of the lever 6, where the lever 6 is equivalent to the arm of the ironing roller described in the background technology . The projection point B of the axis of rotation of the lever 6, the projection point A of the winding roller 1 axis, and the projection point C of the coil 3 at the tangent away from the angle wrapping roller 4, the three projection points are located on the same straight l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com