An anti-corrosion, anti-rust and plastic-spraying process for the sheet metal manufacturing shell of the ring network cabinet

An anti-corrosion and anti-rust, cabinet sheet metal technology, applied in the direction of liquid injection device, injection device, etc., can solve the problems of different area range, different coating, coating thickness, etc., to avoid uneven coating and avoid coating thickness thicker effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to make the techniques of the present invention, the creation characteristics, the purpose and efficacy are easy to understand, and the present invention is further illustrated in connection with the specific illustration. It should be noted that the features of the present application and the features in the embodiments in the present application can be combined with each other.

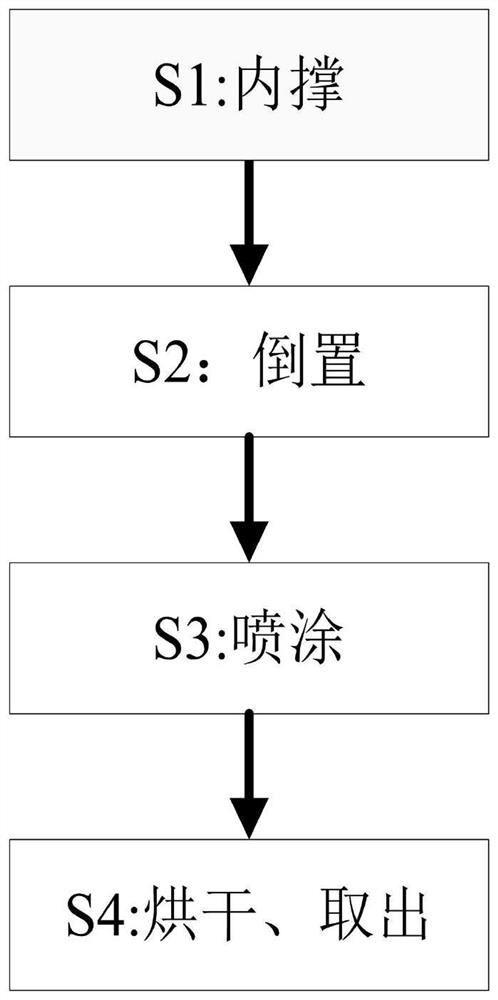

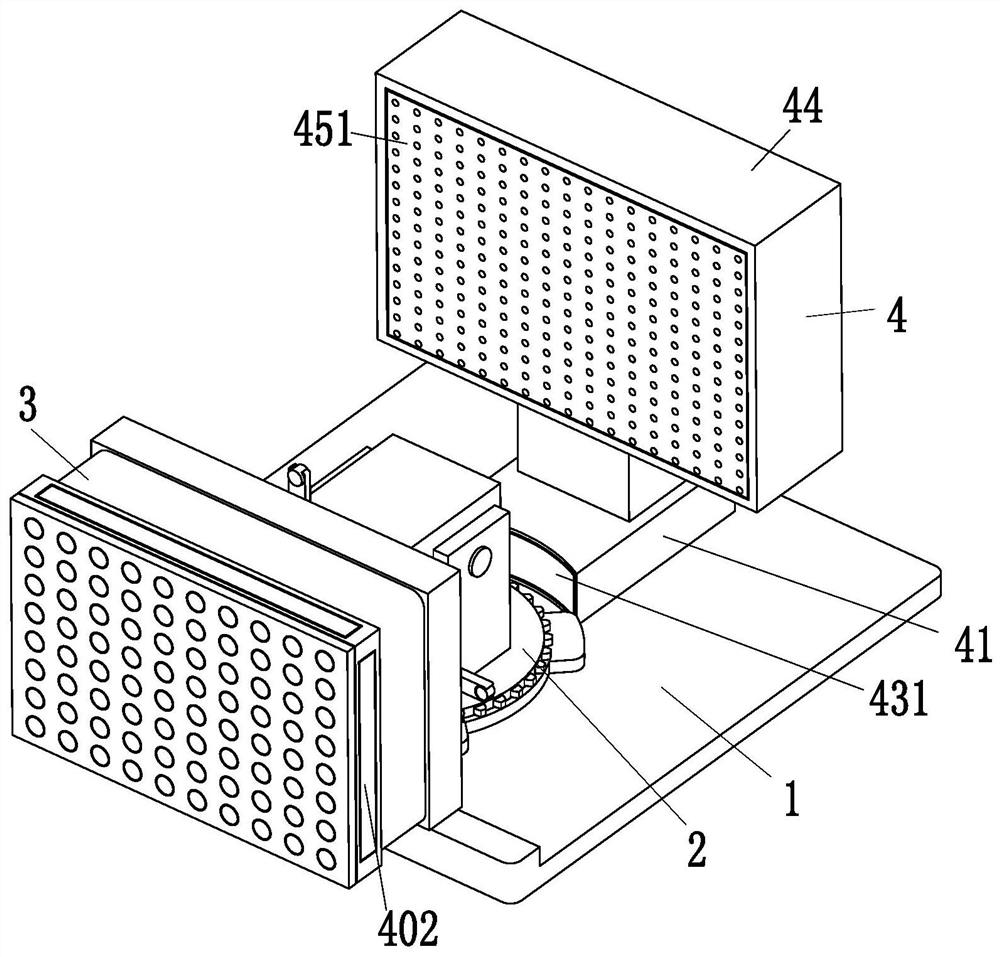

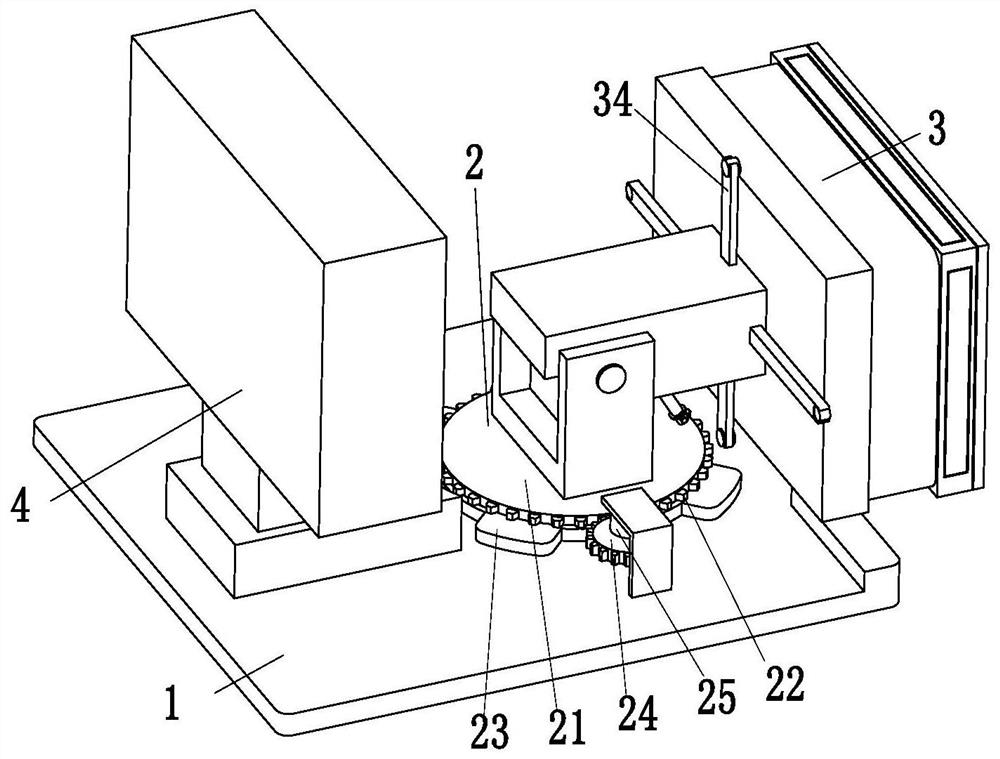

[0032] like Figure 1 to 6 As shown, a ring cabinet sheet metal manufactured a housing preservative anti-rust spray process, which uses a surface spraying apparatus including a bottom plate 1, a rotating unit 2, an inner support unit 3, and a spray unit 4. The above surface spraying equipment is used to make housing anti-corrosion anti-rust spray processes as follows:

[0033] S1, inner support: The inner portion of the housing housing is reached forward by pushing the cylinder 37 to enter the interior of the ring cabinet housing, and the inside of the housing is sucked by the intraoperat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com