Split charging equipment for fry screening

A technology of sub-packaging and equipment, applied in the application, fish farming, animal husbandry and other directions, can solve the problems of increased worker fatigue, difficult to control the size of fry, easy to damage fry, etc., to improve the efficiency of classification, complete classification, reduce effect of fatigue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

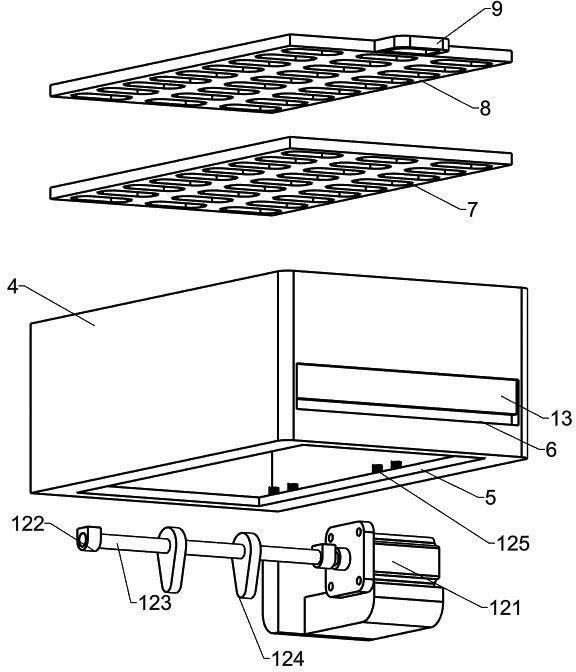

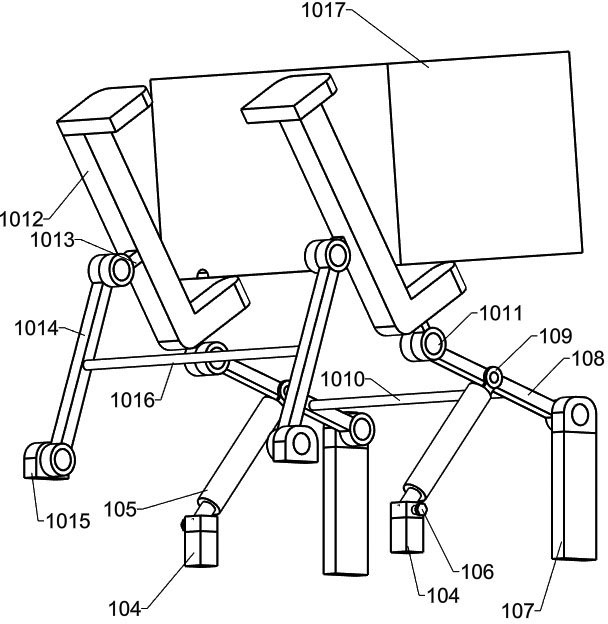

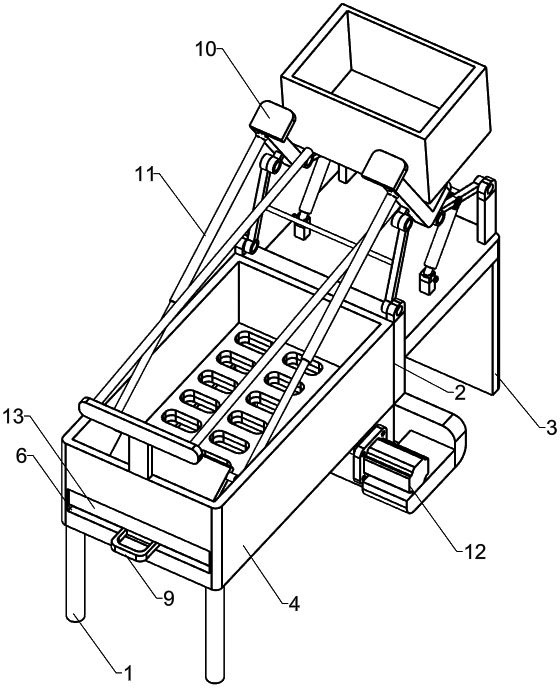

[0042] A sub-packaging device for fry screening, such as figure 1 , figure 2 , Figure 5 As shown, it includes a support column 1, a long plate 2, a first L-shaped plate 3, a screening box 4, a first sieve plate 7, a second sieve plate 8, a handle 9 and a moving plate 13. A screening box 4 is connected with the left side of the long board 2. When the staff needs to screen and pack the fry, they can first pour the fry into the screening box 4, and the right side of the long board 2 is connected with the first L-shaped board 3 , the bottom of the screening box 4 is provided with a first rectangular slot 5, the left side of the screening box 4 is provided with a second rectangular slot 6, the bottom wall of the screening box 4 is provided with a first sieve plate 7 and a second sieve plate 8, the first sieve plate 7 Located below the second sieve plate 8, the left side of the second sieve plate 8 is connected with a handle 9, then pull the handle 9 to the left at a small dista...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com