Agricultural film hole forming device

A technology of agricultural film and rotary rod

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0022] Example 1

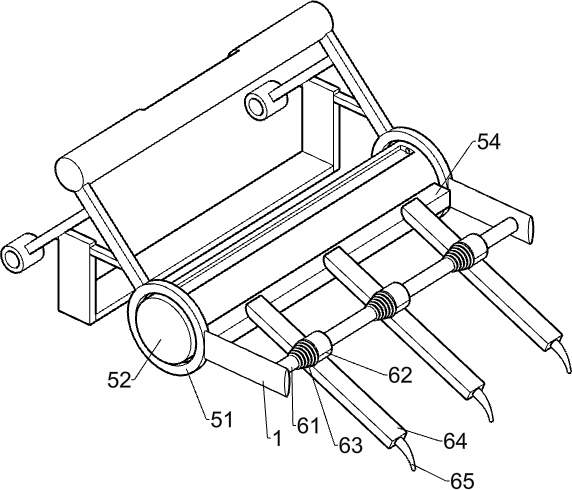

[0023] A device for opening agricultural membranes, such as figure 1 As shown, it includes a bracket 1, a rotating rod 2, a handle 3, a moving mechanism 4, a pitch adjusting mechanism 5, and an opening mechanism 6. The upper side of the bracket 1 is rotatably connected with a rotating rod 2, and the right side of the rotating rod 2 is fixed The handle 3 is connected, the moving mechanism 4 is connected between the right sides of the bracket 1, the pitch adjustment mechanism 5 is connected between the left sides of the bracket 1, and the left side of the bracket 1 is connected with an opening The mechanism 6 and the opening mechanism 6 are located on the left side of the pitch adjusting mechanism 5.

[0024] When people need to make holes for the agricultural film, they put the device on the soil covered with the agricultural film so that the parts of the opening mechanism 6 are on the agricultural film, and then people start the parts of the moving mechanism 4 an...

Example Embodiment

[0025] Example 2

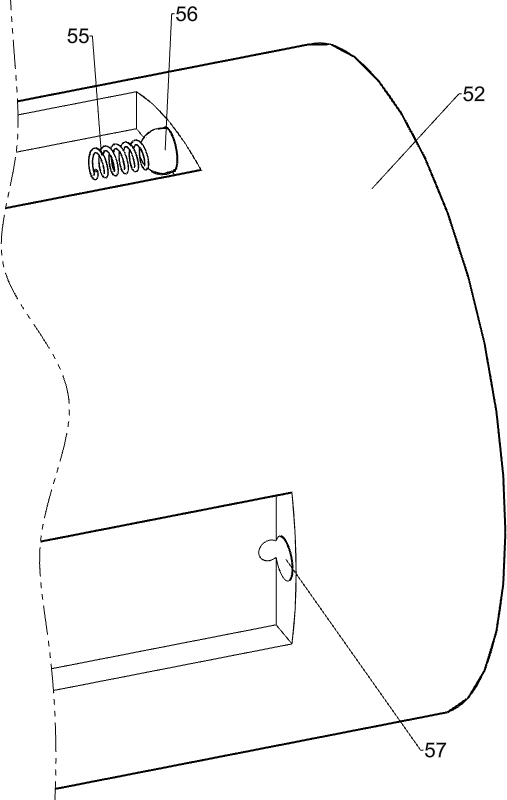

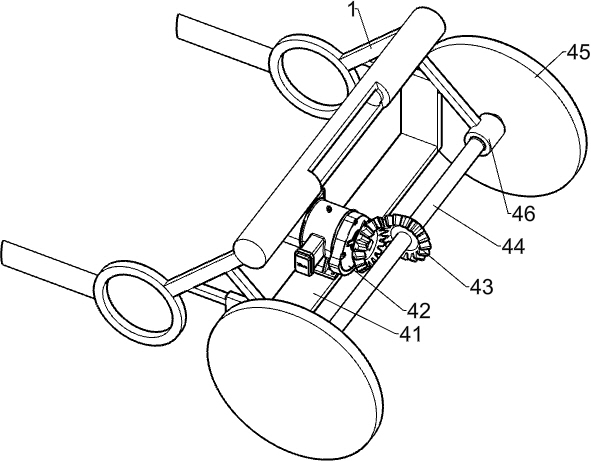

[0026] On the basis of Example 1, such as Figure 2-7 As shown, the moving mechanism 4 includes a support plate 41, a motor 42, a bevel gear set 43, an axle 44, a front wheel 45, and a first support shaft 46. The support plate 41 is connected to the lower side of the bracket 1, and the top of the support plate 41 is provided There is a motor 42, the right end of the bracket 1 is connected to a first support shaft 46, the middle of the first support shaft 46 is rotatably connected to an axle 44, the end of the axle 44 is provided with front wheels 45, the middle of the axle 44 and the motor 42 A bevel gear set 43 is provided on the output shaft, and the two bevel gear sets 43 mesh with each other.

[0027] When people need to move the device, people start the motor 42, the rotation of the output shaft of the motor 42 drives the bevel gear set 43 to rotate, the bevel gear set 43 rotates to drive the axle 44 to rotate, and with the cooperation of the first support ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com