Dustproof structure of optical fiber adapter

A technology of fiber optic adapter and dust-proof structure, which is applied in light guides, optics, instruments, etc., and can solve problems such as small operating space, interruption of communication services, and easy accidental injury

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

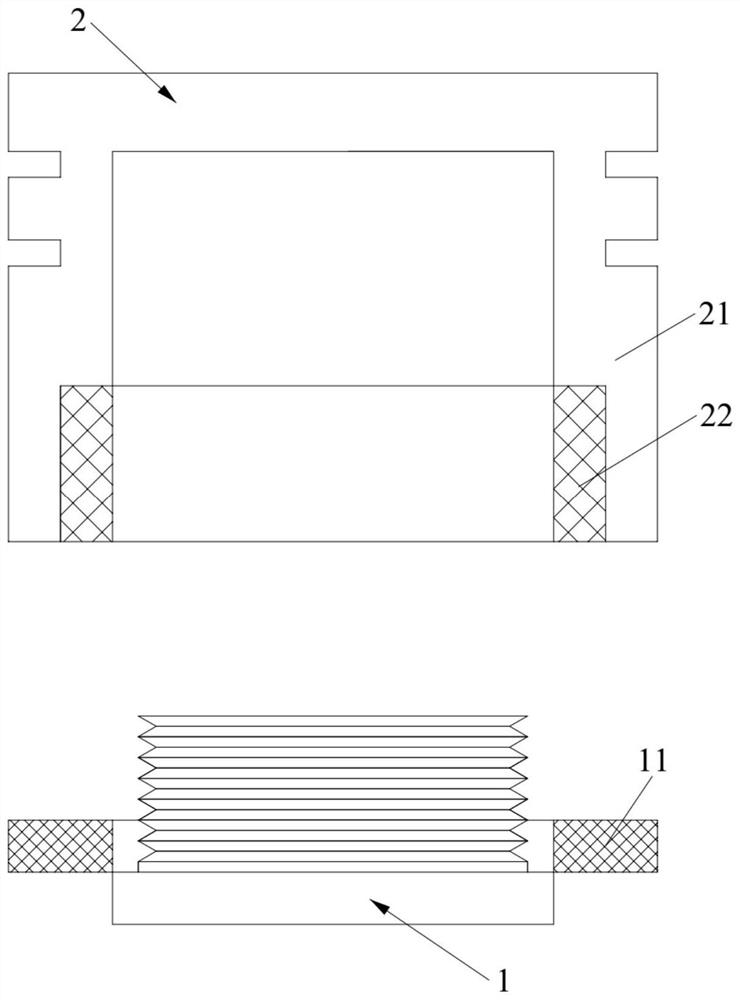

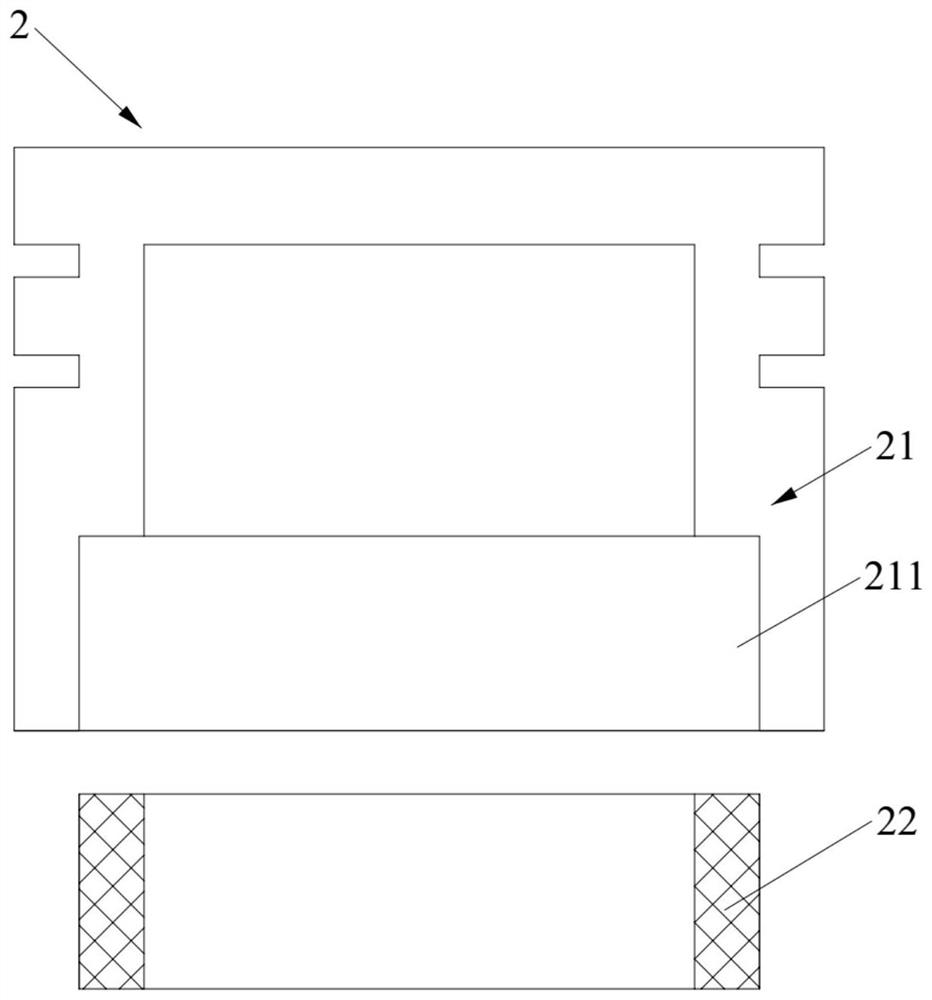

[0035] This embodiment provides a dustproof structure for an optical fiber adapter. Such as figure 1 As shown, the fiber optic adapter dustproof structure includes a fiber optic adapter 1 and a dustproof cover 2 . The end of the fiber optic adapter 1 is fixed with a first magnetic member 11 . The dustproof cover 2 includes a cover body 21 and a second magnetic part 22 fixedly connected with the cover body 21. The cover body 21 is arranged on the end of the optical fiber adapter 1, and the second magnetic part 22 can be attracted to the first magnetic part 11 to The fixing between the cover body 21 and the end of the optical fiber adapter 1 is realized. When the dustproof cover 2 needs to be removed, the staff can easily overcome the suction force between the second magnetic part 22 and the first magnetic part 11 by hand, thereby realizing the separation of the cover body 21 from the end of the dustproof cover 2 . Since the cover body 21 and the second magnetic member 22 are...

Embodiment 2

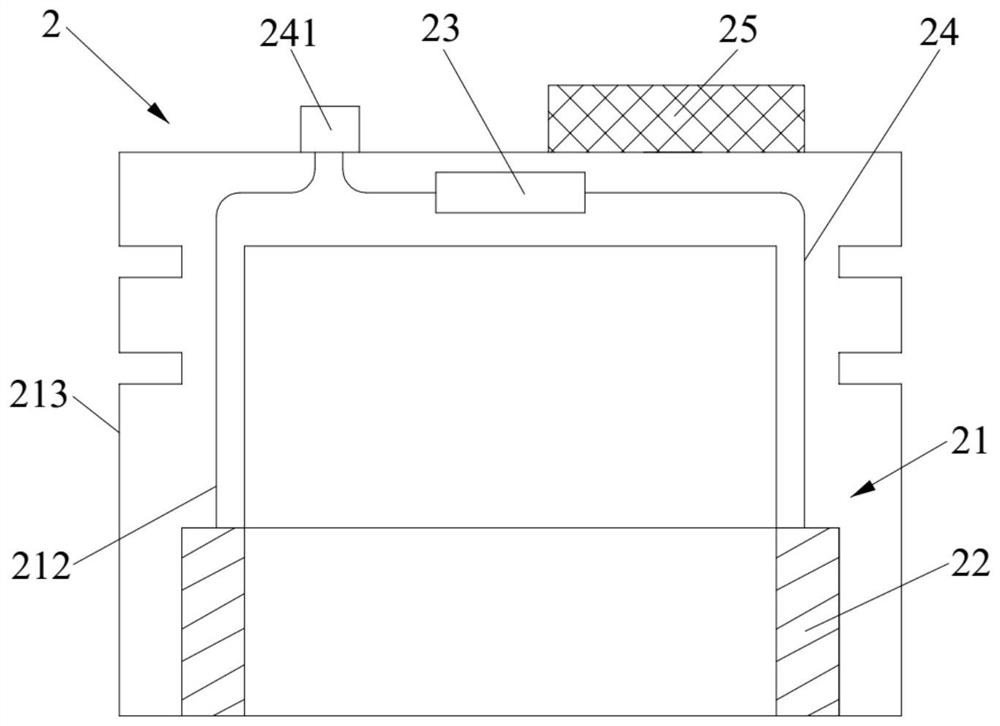

[0051] This embodiment provides a dust-proof structure for an optical fiber adapter, such as image 3 As shown, it is roughly the same as the dustproof structure of the optical fiber adapter provided in Embodiment 1, the only difference is that: the dust cover 2 also includes a power supply 23; the second magnetic member 22 is an electromagnetic induction coil, and the electromagnetic induction coil is electrically connected to the power supply 23, Moreover, the electromagnetic induction coil is configured to be able to attract the first magnetic member 11 when connected to the power source 23 .

[0052] At this time, the power supply 23 can supply power to the electromagnetic induction coil, so that the electromagnetic induction coil has magnetism to attract and engage with the first magnetic member 11 . On this basis, the magnetic strength of the second magnetic part 22 can be adjusted by pre-adjusting the number of turns of the electromagnetic induction coil and the size of...

Embodiment 3

[0058] This embodiment provides a dust-proof structure for an optical fiber adapter, such as Figure 4 As shown, it is roughly the same as the dust-proof structure of the optical fiber adapter provided in Embodiment 1, the only difference is that: the end of the cover body 21 facing the optical fiber adapter 1 is provided with a limiting groove 214, and the first magnetic ring (that is, the first magnetic member 11) When docking with the second magnetic ring (that is, the second magnetic member 22 ), the limiting groove 214 can be engaged with the first magnetic ring.

[0059] Click here to set, such as Figure 5 As shown, after the first magnetic part 11 is docked with the second magnetic part 22, the radial movement of the dust cover 2 can be limited by the cooperation of the limit groove 214 and the first magnetic part 11, so as to ensure the stable installation of the dust cover 2 sex.

[0060] Specifically, combined with figure 2 and Figure 4 , the limiting groove 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com