Spring type piezoelectric air pump

A spring-type, electric pump technology, applied in the direction of variable-capacity pump components, pumps, pump components, etc., can solve the problems of limited deformation capacity of diaphragm piezoelectric vibrators and poor gas output effect, so as to improve the working effect, Simple structure and small volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

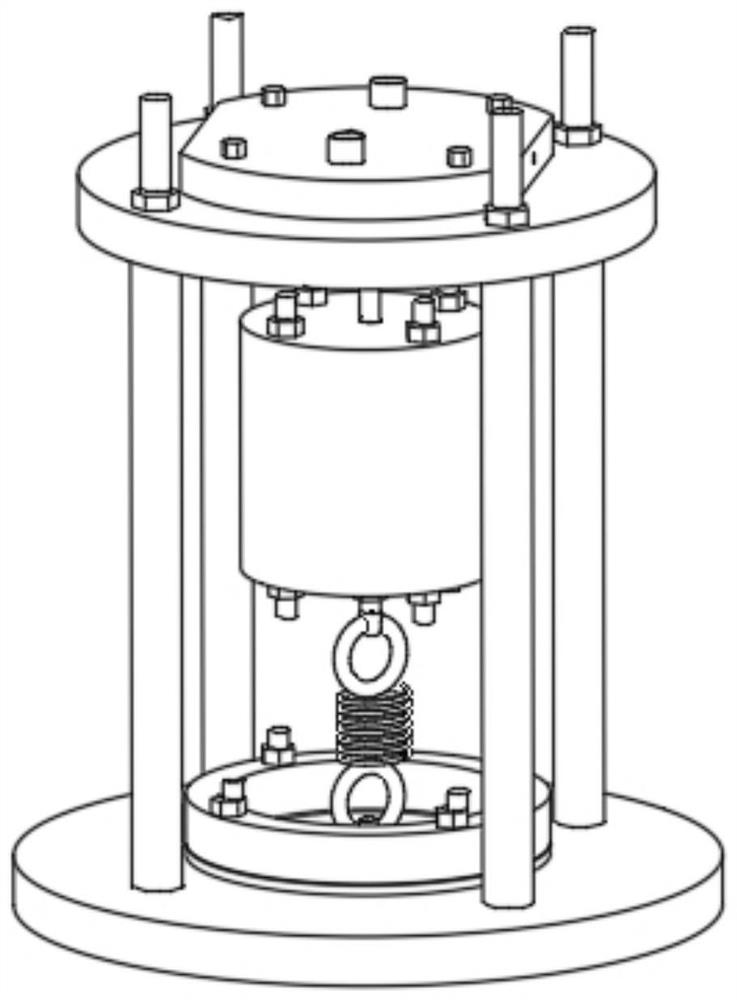

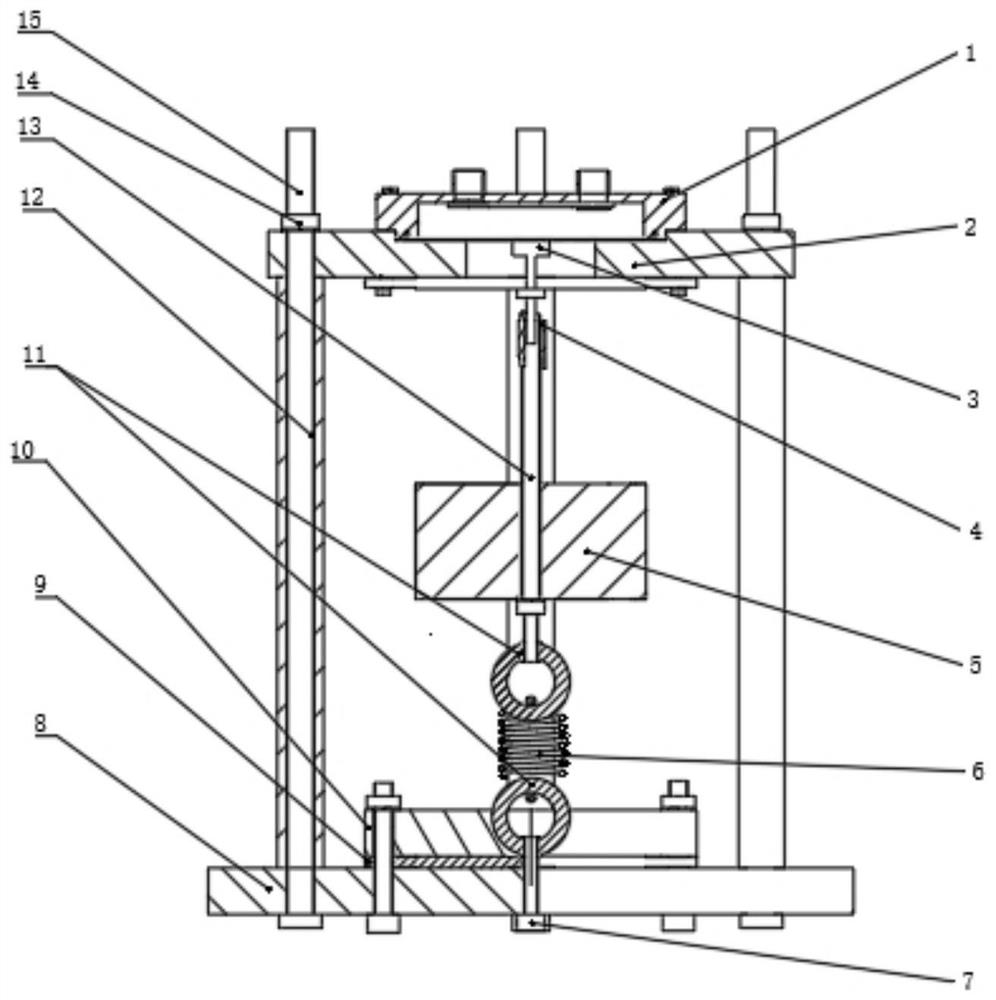

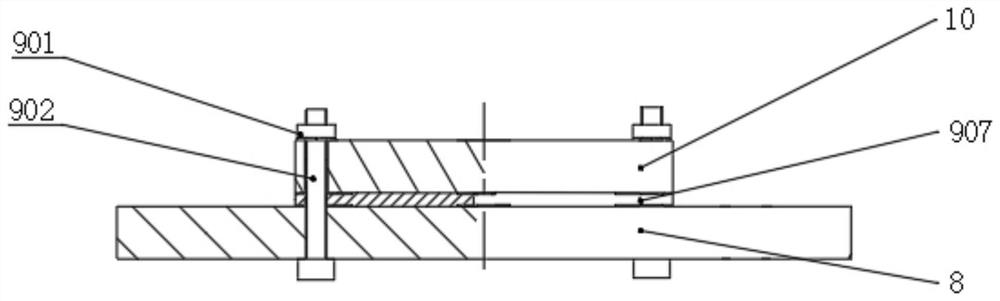

[0021] See Figure 1-5 , a spring-type piezoelectric pump, including a base 8, the base 8 is a disc-shaped structure, the top surface of the base 8 is provided with a positioning ring 10, the positioning ring 10 is a circular structure, the base 8 The axis coincides with the axis of the positioning ring 10. A vibrator fixing structure 9 is provided between the positioning ring 10 and the base 8. The vibrator fixing structure 9 includes third bolts 902. The positioning ring 10 is fixed on the base by several third bolts 902. 8, the third bolt 902 is covered with a first nut 901, and a first piezoelectric vibrator 907 is also provided between the positioning ring 10 and the base 8, and the top edge of the base 8 is in a circular array Be provided with some columns 12, described column 12 is circular tubular structure, and the top of all columns 12 is provided with lower cavity 2 jointly, and described lower cavity 2 is installed on the column 12 by screw rod 15, and the top of d...

Embodiment 2

[0024]The difference from Embodiment 1 is that the bottom of the lower cavity 2 is provided with a second piezoelectric vibrator 903, and the second piezoelectric vibrator 903 is installed on the lower cavity 2 through a second bolt 904. The piezoelectric vibrator 903 is installed on the joint 3 through the second nut 906. By setting the second piezoelectric vibrator 903 as another driving source, the second piezoelectric vibrator 903 directly drives the joint 3 to vibrate at a close distance, and then drives the entire device to operate. , the working efficiency of the whole device can be increased, and the second piezoelectric vibrator 903 cooperates with the first piezoelectric vibrator 907 to further expand the amplitude and further improve the working effect of the whole device.

[0025] The working principle of Embodiment 1-2: the present invention uses the first piezoelectric vibrator 907 as the driving source, and then uses the spring 6 to cooperate with the resonant ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com