Baking and shaping device based on vacuum switch tube

A technology of vacuum switch tube and sizing device, which is applied to electric switches, household refrigeration devices, high-voltage/high-current switches, etc. issues of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

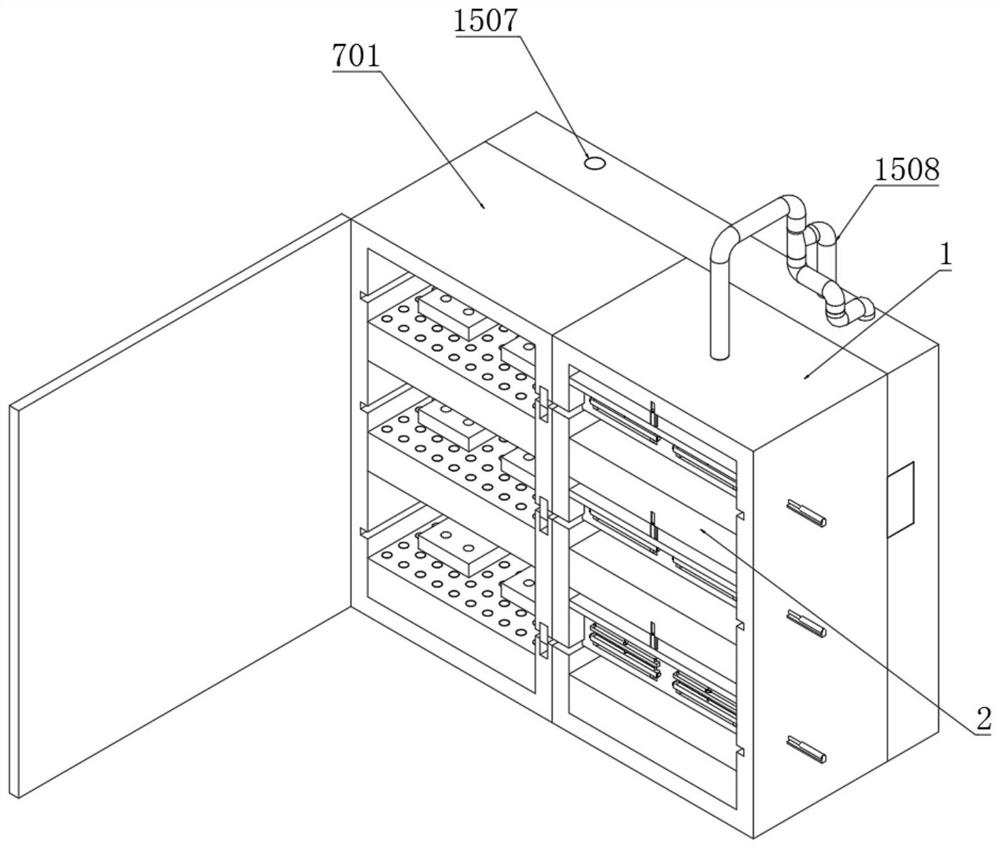

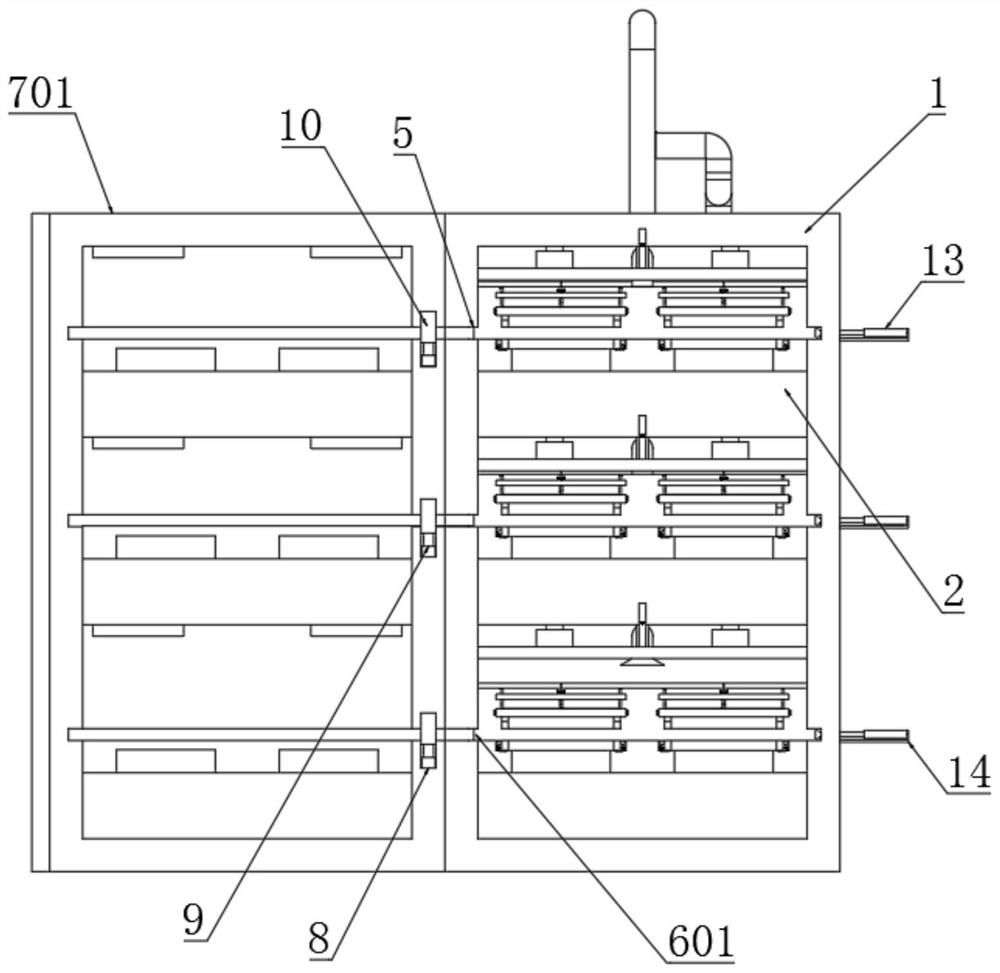

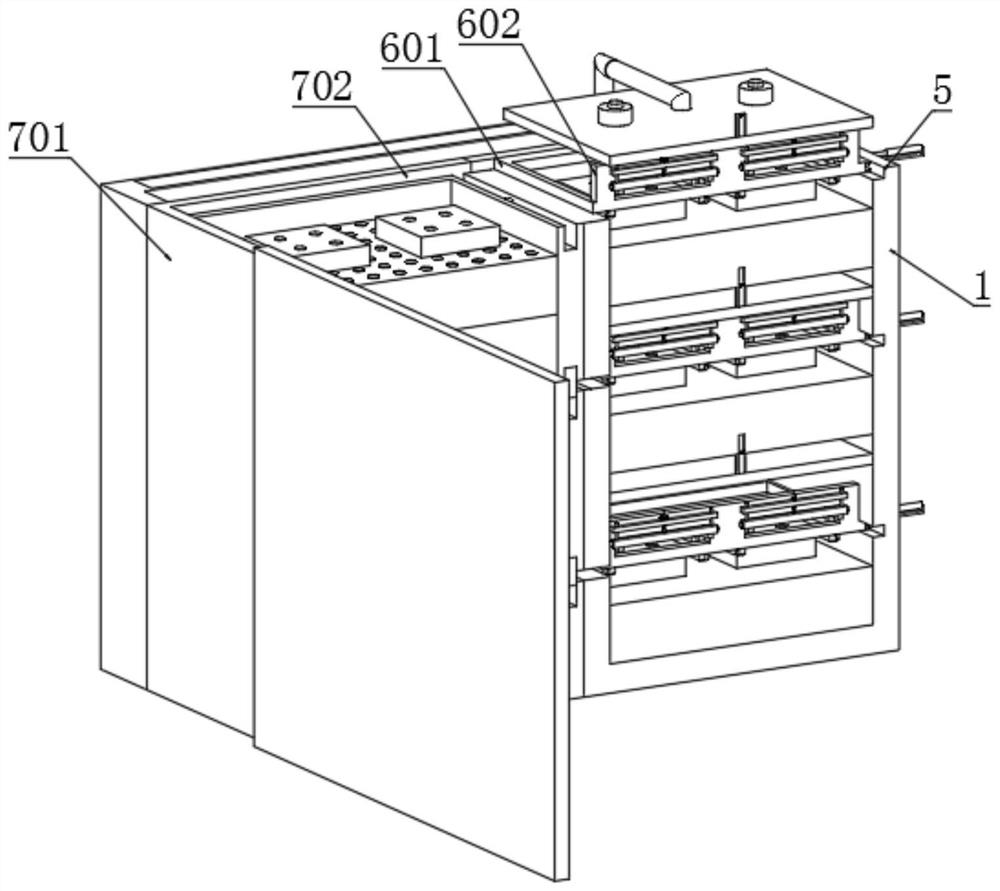

[0060] Example: such as Figure 1-20 As shown, the present invention provides a technical solution, a vacuum switching tube-based baking and setting device, including a baking oven 1, the inner wall of the oven 1 is equidistantly welded with a partition plate 2, and the front of the inner wall of the oven 1 corresponds to The position of the top edge of the partition plate 2 is provided with a moving groove 5, the front of the inner wall of the oven 1 is fixedly installed with a heater 3 corresponding to the position of the top edge of the moving groove 5, and both sides of the inner wall of the partition plate 2 are fixedly installed with Clamping and rotating mechanism 4;

[0061] The clamping and rotating mechanism 4 includes a motor 401, a positioning gear 402, a rotating gear 403, a rotating plate 404, a groove 405, a matching hole 406, a mold plate 407, a placement hole 408, a bearing 409, a main threaded rod 410, a nut 411, and a moving sleeve Pipe 412, main moving gro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com