Unmanned mine drilling and blasting trolley

A trolley and mine technology, applied in blasting, drilling equipment and methods, earthwork drilling and mining, etc., can solve the problems of casualties, accidents, etc., and achieve the effect of ensuring construction safety and convenient multi-angle drilling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

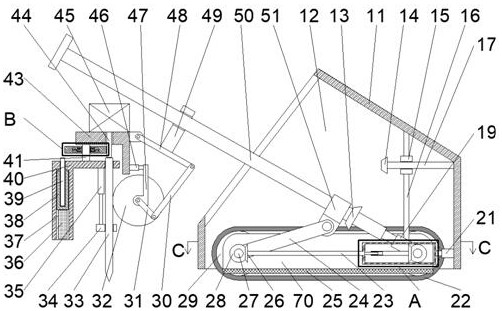

[0014] Combine below Figure 1-Figure 4 The present invention is described in detail, and for convenience of description, the orientations mentioned below are now stipulated as follows: figure 1 The up, down, left, right, front and back directions of the projection relationship itself are the same.

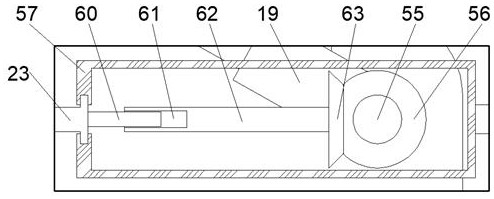

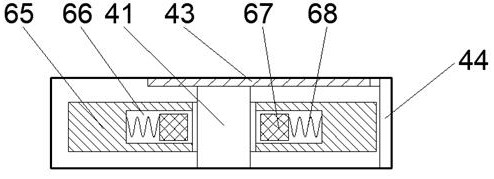

[0015]An unmanned mine drilling and blasting trolley according to the present invention includes a car body 11, a working chamber 12 is arranged in the car body 11, and an auxiliary motor 54 is fixed in the rear wall of the working chamber 12. The front end of the auxiliary motor 54 is power-connected with a main shaft 55, the front end of the main shaft 55 is rotatably connected to the front wall of the working chamber 12, the main shaft 55 is rotatably connected to a base 25, and the base 25 is provided with a slot 70 with an upward opening. , the front and rear ends on the left side of the base 25 are rotatably connected to the front and rear walls of the working chamber 12 re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com