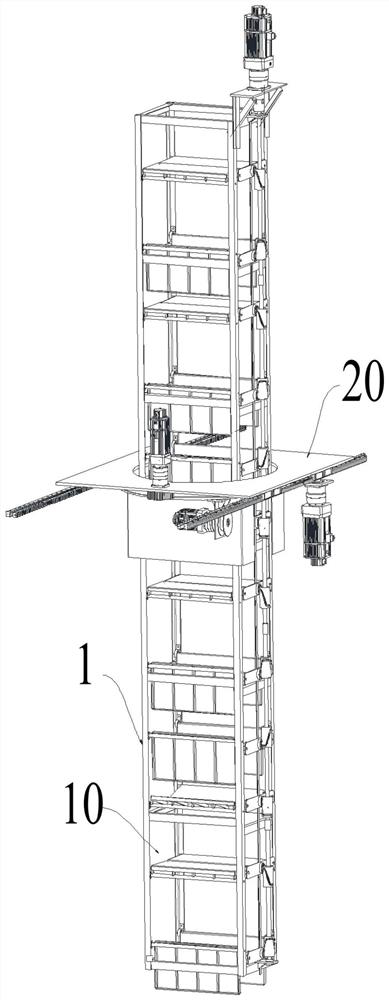

Relay type loading and bag placement device

A material package, transmission connection technology, applied in the direction of transportation and packaging, loading/unloading, etc., can solve problems such as inconvenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

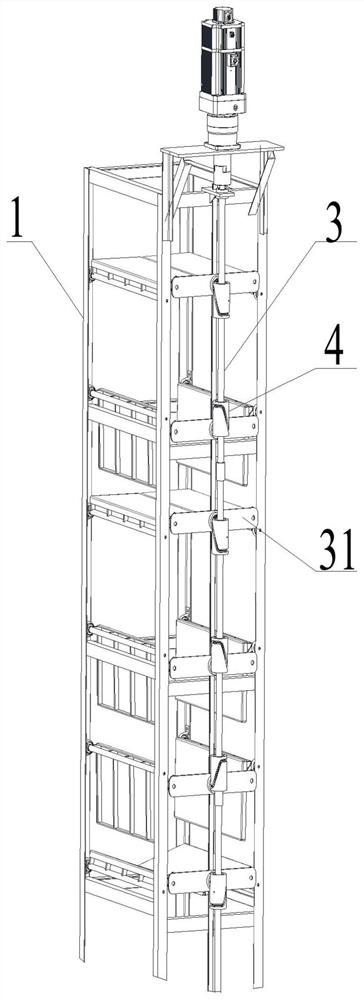

Embodiment 1

[0078] The length of the closed section 41 and the open section 43 etc.; and the length of the closed section 41 and the transition section 42 are equal, that is, the length of the closed section 41 is 1 / 4 of the entire track groove period; the phase difference between two adjacent track cylinders 4 is 90 °;

[0079] see Figure 7 , with the closing segment 41 starting position starting point (t 0 ), and take this layer as the first layer to describe the working principle of the present invention.

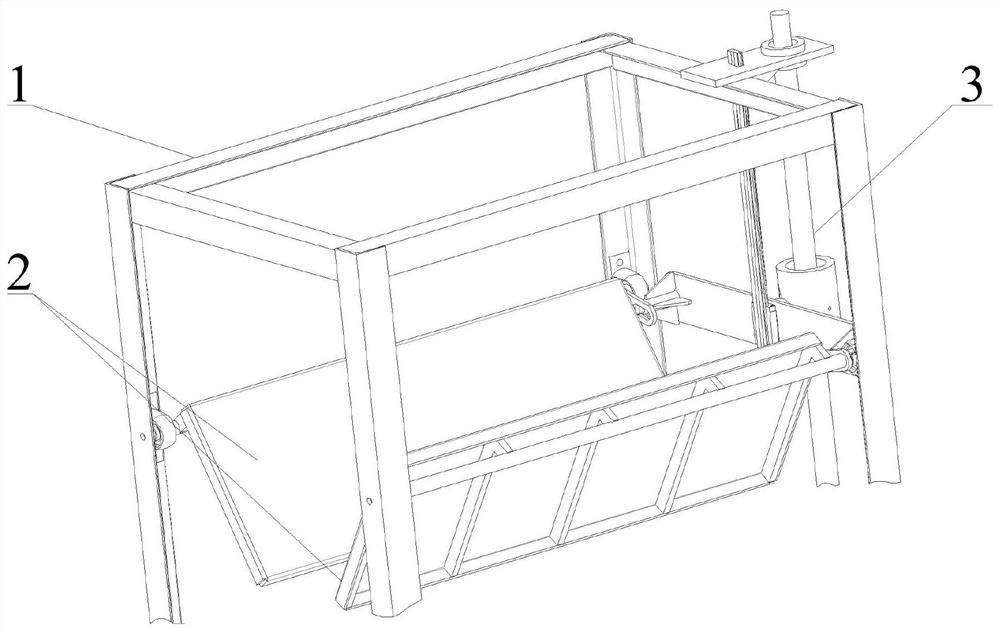

[0080] t 0 time:

[0081] The first layer: the raised portion of the drive plate 31 runs at the starting point of the closing section 41, and the two pallets 2 of this layer are in a closed state; a material bag is placed on this layer;

[0082] The second layer: the raised portion of the drive plate 31 runs at the end point of the opening section 43, and the two pallets 2 of this layer are in an open state;

[0083] The third layer: the raised portion of the drive plate 31 ru...

Embodiment 2

[0100] The length of the closed section 41 is 60% of the length of the open section 43; the length of the closed section 41 is 1 / 4 of the period of the entire track groove; the phase difference between two adjacent track cylinders 4 is 90°;

[0101] see Figure 8 , each layer at t 0 to t 2 The state change at any moment can be analyzed in the aforementioned manner, and will not be repeated here.

[0102] Because the length of the opening section 43 is obviously greater than the length of the closing section 41, the two pallets 2 on the upper floor remain fully open during the process of the material package on the next floor falling from the beginning to completely falling, and will not be touched. Material package (t 0 to t 1 time, the state of the third and fourth layers).

Embodiment 3

[0104] The length of the closed section 41 is less than the length of the open section 43; and the length of the closed section 41 is 1 / 3 of the entire track groove period; the phase difference between two adjacent track cylinders 4 is 120°; the state of each layer can be analyzed in the aforementioned manner .

[0105] In this embodiment, the opening and closing states of the pallets 2 of the bag-receiving assembly 10 separated by one layer are the same, so a waiting bag can be added every three layers to speed up the rhythm of bag dropping, thereby increasing the number of bags per hour and speeding up the loading process. .

[0106] The phase difference of two adjacent track barrels 4 of the present invention can be done adaptive setting according to the rotating speed of connecting rod 3; Rotating speed is slow, and then phase difference is little; Rotating speed block then phase difference is big; The phase difference of the present invention is preferably 60 °, 90° or 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com