Supporting mechanism for turnover box

A supporting mechanism and turnover box technology, which is applied in the field of mechanical equipment, can solve the problems of high requirements, failure to meet the requirements of the support mechanism, and large volume of the turnover box.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

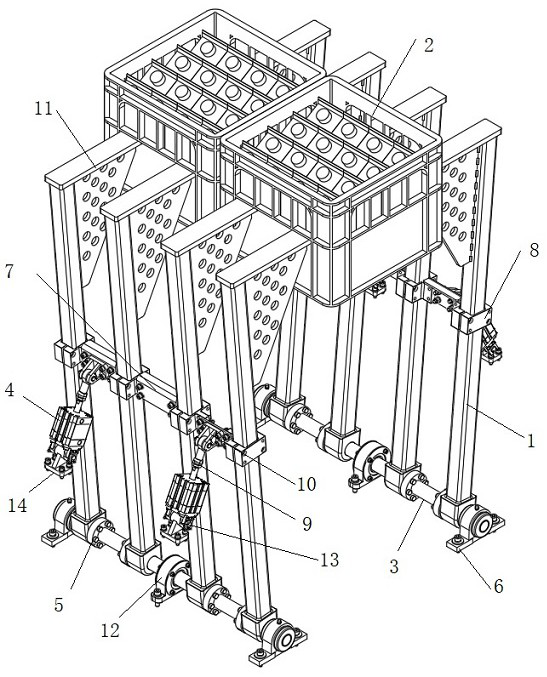

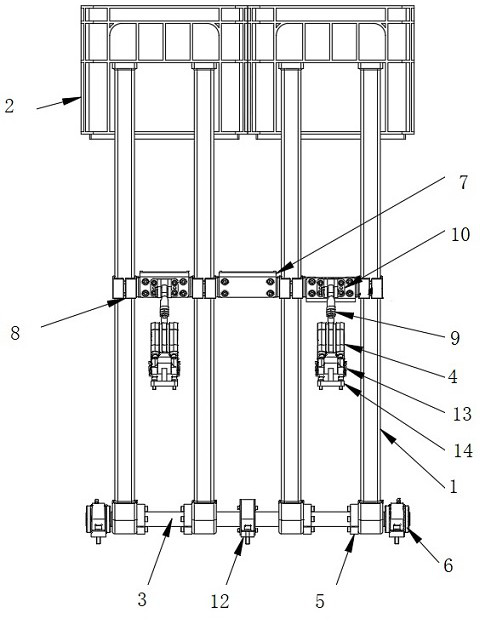

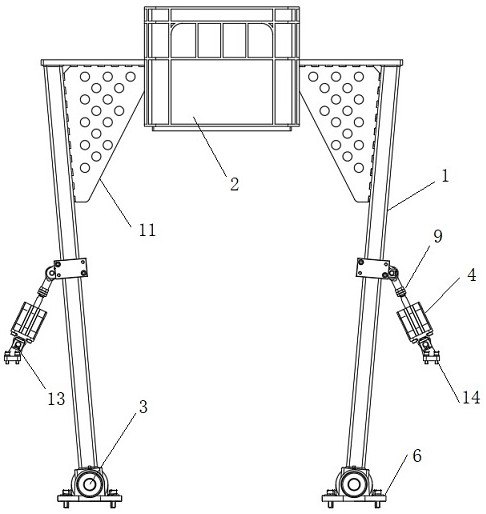

[0025] Its power is provided by the cylinder, and the linear motion of the cylinder is converted into the rotary motion of the support arm around the rotating shaft through the double clevis support, double ear cylinder seat, joint bearing and ball hinge clevis support. The connection between the rotating shaft and the external frame adopts a self-made belt seat Bearings and bearings with seats reduce the rigid friction between machines and reduce the requirements for cylinder force. At the same time, in order to ensure the synchronous movement of support arms in structure, C-shaped clamps and long connecting plates are used to maintain rigid connections between support arms. The supporting part of the support arm is welded with reinforcing ribs, and the reinforcing ribs are triangular plates to ensure its strength.

[0026] When the cylinder is fully extended, the support arm swings to the inside and reaches the position to support the turnover box. At this time, the center of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com