Automatic tender coconut processing machine

A processing machine, coconut green technology, applied in the field of automatic coconut green processing machine, can solve the problems of physical and mental damage, unstable center of gravity, low efficiency and other problems of operators, so as to reduce personal injury accidents, reduce labor costs, and ensure personal safety. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

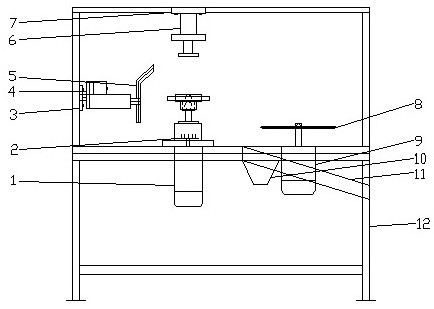

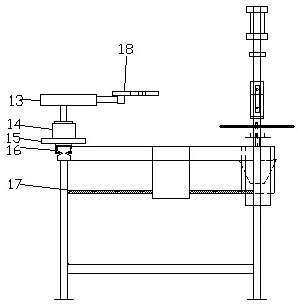

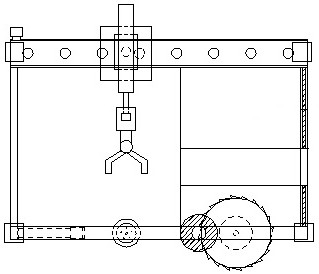

[0013] There is a frame 12, the main motor 1 is arranged on the frame 12, the spike disc 2 is arranged on the main motor 1, the electric push rod 4 is arranged on the left side of the spike disc 2, and the front end of the electric push rod 4 is provided with a forming tool 5. A compression cylinder 6 is provided above the nail tooth disc 2, and a coconut bottom cutting device is provided on the right side of the nail tooth disc 2. The coconut bottom cutting device is provided with a cutting motor 9, and a disc knife is arranged on the cutting motor 9. 8. Between the cutting motor 9 and the main motor 1, there is a coconut bottom material opening 10, the rear portion of the coconut bottom material opening 10 is provided with a material receiving trough 11, and the rear part of the nail tooth plate 2 is provided with a manipulator device, and the manipulator Device is provided with moving slide rail 16, and moving slide rail 16 is provided with lift cylinder 14, and lift cylinde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com