Motor truck scale system

A technology for truck scales and tunnels, which is applied in the field of truck scale systems, and can solve problems such as poor sealing performance, poor working stability, and high maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

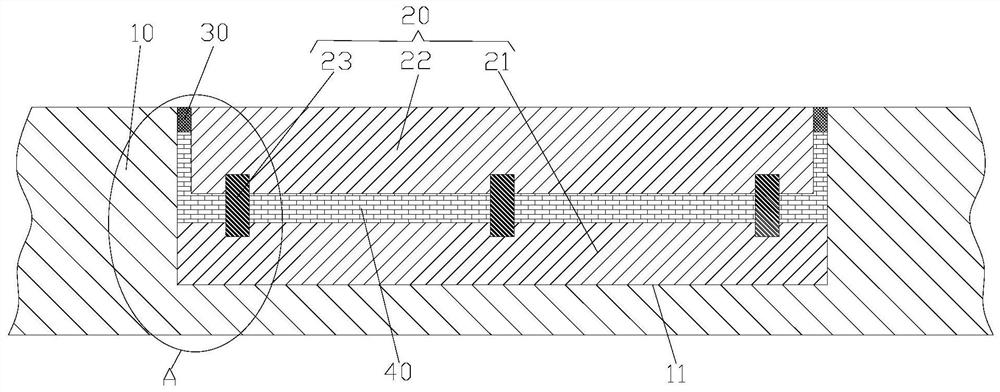

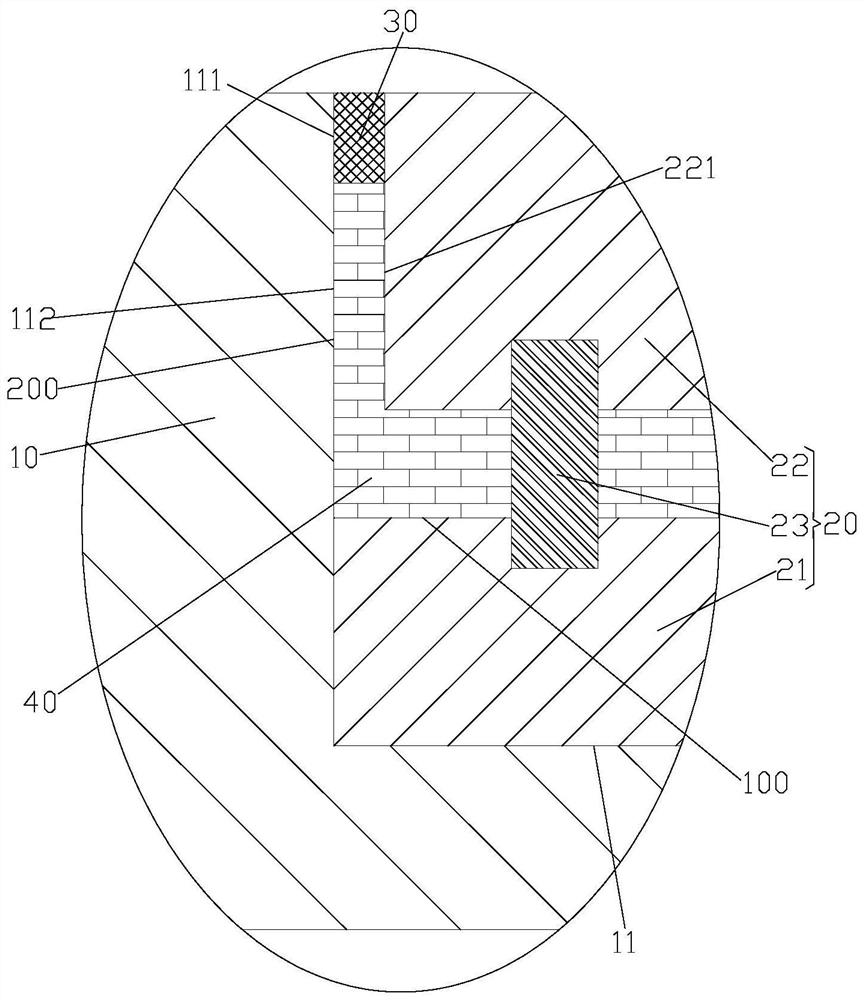

[0026] Such as figure 1 and figure 2 As shown, the truck scale system has a waterproof and dustproof function, and it includes an installation base 10, a dynamic truck scale 20, and a sealing part 30. The installation base 10 has an installation tunnel 11, and the dynamic truck scale 20 is arranged in the installation tunnel 11, and the dynamic truck scale The scale 20 and the installation foundation 10 form an annular installation gap 111 at the mouth of the installation tunnel 11, and the sealing part 30 is continuously arranged around the annular installation gap 111. The sealing part 30 and the dynamic truck scale 20 jointly seal the mouth of the installation tunnel 11 to prevent water Or dust enters the installation tunnel 11.

[0027] By continuously setting the sealing part 30 at the annular installation gap 111 formed by the mouth of the dynamic truck scale 20 and the installation tunnel 11, the sealing part 30 and the dynamic truck scale 20 jointly seal the mouth of...

Embodiment 2

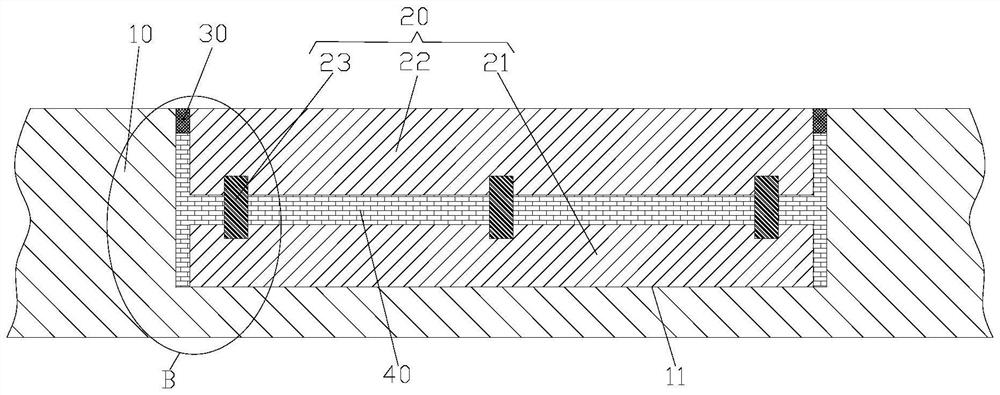

[0040] Such as image 3 with Figure 4 As shown, the difference between this embodiment and Embodiment 1 is that a third filling space 300 is formed between the second outer peripheral surface 211 of the support structure layer 21 and the circumferential inner wall surface 112 of the installation tunnel 11, and the third filling space 300 At least a portion of is provided with a filling barrier 40 . In this way, it is not only possible to avoid the accumulation of water or dust in the installation tunnel 11 , but also to facilitate the installation of the supporting structure layer 21 into the installation tunnel 11 .

[0041] Optionally, the first filling space 100 communicates with the second filling space 200 and the third filling space 300 .

[0042] From the above description, it can be seen that the above-mentioned embodiments of the present invention have achieved the following technical effects: the support structure layer 21 and the load-bearing structure layer 22 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com