Anti-clogging rainwater grate for municipal roads

A rainwater grate, municipal road technology, applied in water supply installations, waterway systems, drainage structures, etc., can solve problems such as water inlets being easily blocked by impurities, pedestrians and vehicles traveling, and people's quality of life being reduced. Practicality, the effect of improving the range of activities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

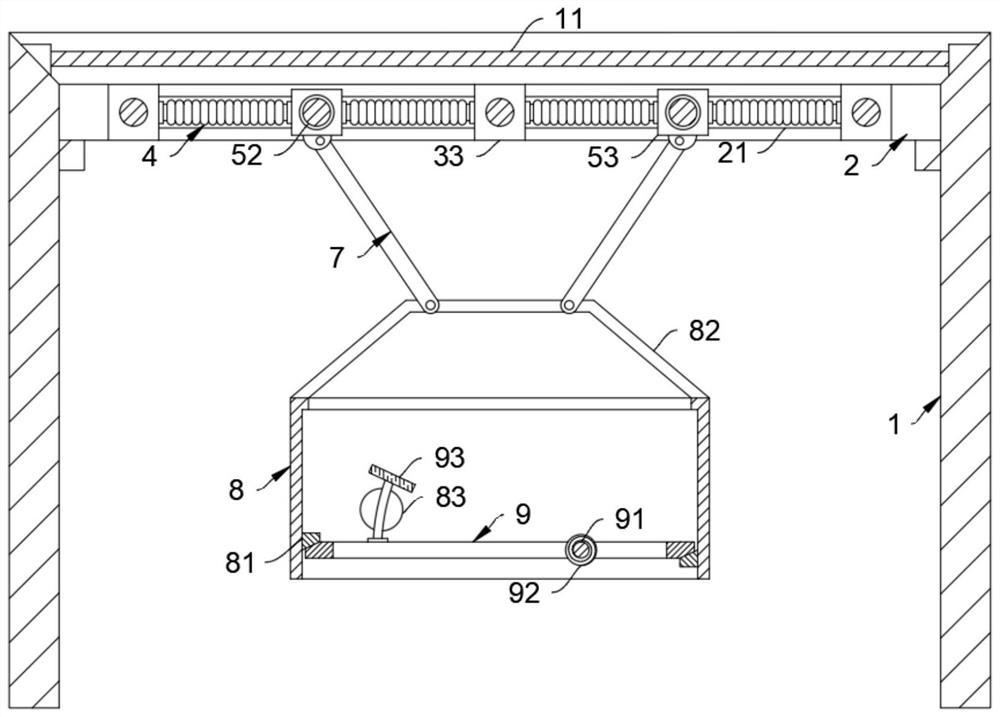

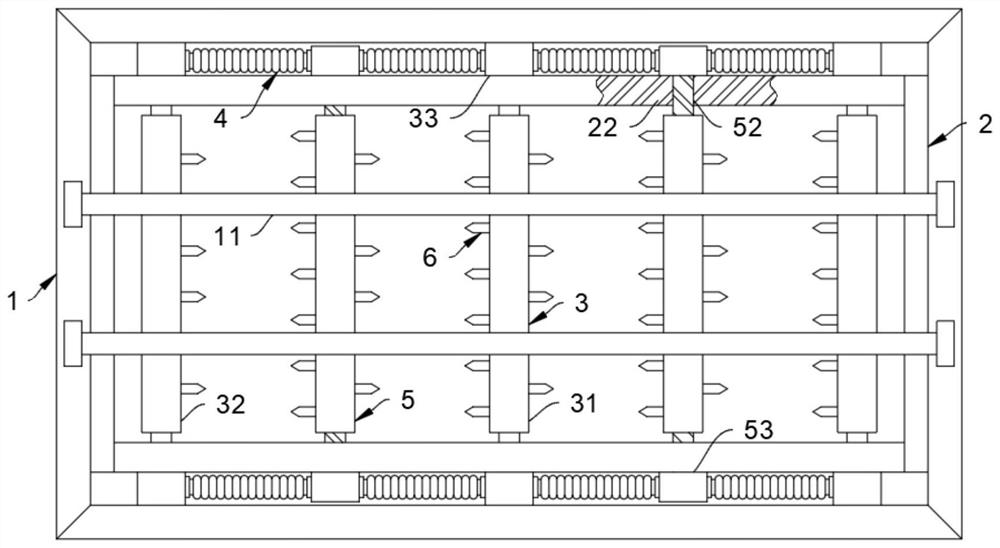

[0028] Such as Figure 1-2 As shown, a kind of anti-clogging rainwater grate for municipal roads comprises a support frame 1, and the support frame 1 is detachably connected with a cover plate 2. The staff works on the placement of the device.

[0029] The cover plate 2 is provided with a fixed rod 3, and a movable rod 5 is movably connected between adjacent fixed rods 3 through a spring tube 4. It should be noted that the fixed rod 3 includes a main rod 31 and a side rod 32, and the movable rod 5 is movably connected to the The position between the main rod 31 and the side rod 32.

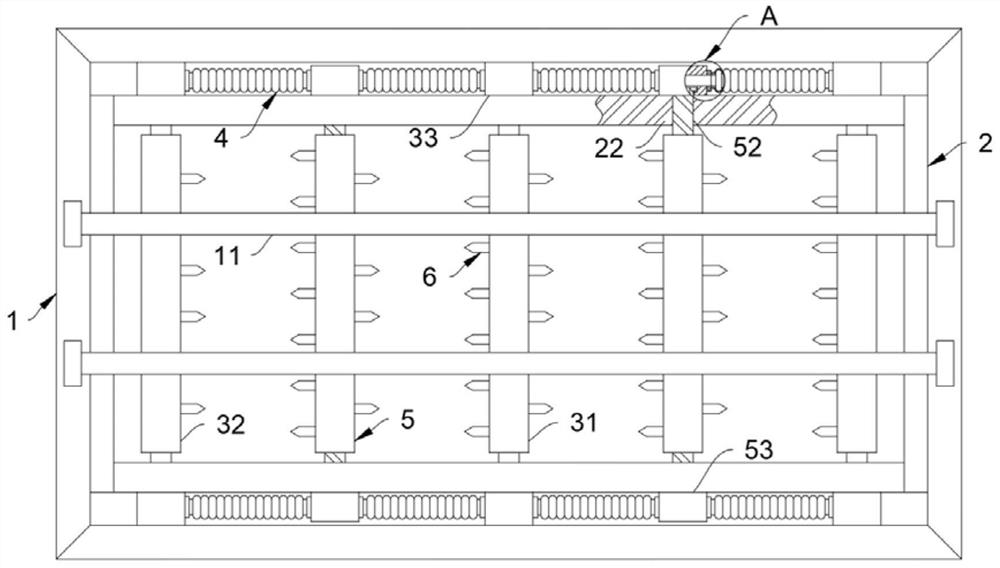

[0030] The specific movable connection process: the cover plate 2 is symmetrically provided with a guide rail 21, the guide rail 21 is provided with a rack 22, and both sides of the moving rod 5 close to the rack 22 are provided with a tooth column 52, through the meshing of the tooth column 52 and the rack 22 , so that the moving rod 5 forms a rotating work during the moving process, which faci...

Embodiment 2

[0041] Such as Figure 3-6 Shown, the difference between this embodiment and embodiment 1 is:

[0042] The fixed rod 3 and the moving rod 5 are all provided with a ventilation layer 51, one end of the ventilation layer 51 communicates with the spring tube 4, the cutting blade 6 is provided with an air outlet 61, and the other end of the ventilation layer 51 communicates with the air outlet 61, and the air outlet 61 is symmetrically arranged on the rotating side of the cutting blade 6 .

[0043] Specifically, the spring tube 4 adopted in this embodiment is a fully sealed spring tube, the main rod 31 of the fixed rod 3 is provided with a double ventilation layer 51, which is used for the intake and exhaust of the spring tube 4 on both sides, and the cutting blade 6 The air outlet holes 61 are arranged symmetrically at the tip of the knife, and the air outlet holes 61 are arranged obliquely so that the cutting blade 6 can blow the airflow to both sides when cutting, so as to imp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com