Lathe auxiliary equipment with tool bit damping function

A technology of auxiliary equipment and cutter head, which is applied in the direction of metal processing equipment, manufacturing tools, metal processing machinery parts, etc., can solve the problems that affect the quality of processed workpieces, affect the assembly of parts, and cannot effectively improve the quality of production products, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

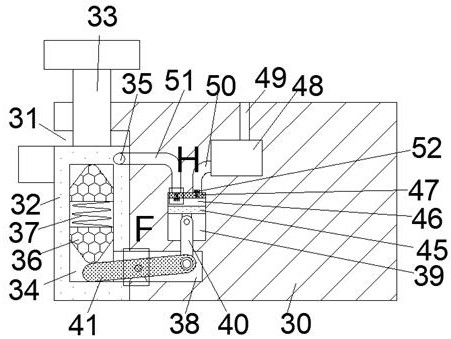

[0025] Combine below Figure 1-Figure 9 The present invention is described in detail, and for the convenience of description, the orientations mentioned below are now stipulated as follows: figure 1 The up, down, left, right, front and back directions of the projection relationship itself are the same.

[0026]A lathe auxiliary device with a cutter head shock absorbing function according to the present invention includes a base 11, and a protective shell 14 is fixed on the upper left side of the base 11, and the protective shell 14 is connected to the base 11. A power cavity 15 is formed between the lower end surfaces, and the right end surface of the protective shell 14 is fixedly provided with a fixed jaw 19 that can be clamped. The workpiece 18 on the left end surface of the protective shell 14, the fixed jaw 19 can clamp the workpiece 18, and the outer side of the axis of the workpiece 18 inside the power chamber 15 is provided with a rotatable sleeve 20, the sleeve 20 T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com