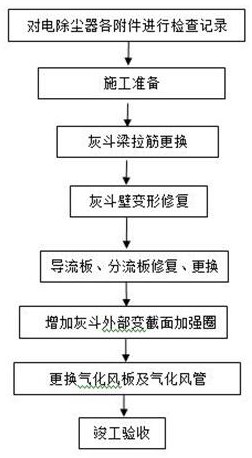

An ESP dust hopper overhaul process

A technology of electrostatic precipitator and electrostatic precipitator, which is applied in the field of overhauling the electrostatic precipitator ash hopper, which can solve problems such as poor ash conveyance, reduced dust removal efficiency, and collapse of the electrostatic precipitator, so as to simplify the way of material reversing, increase the rate of material in and out, Avoid interfering with each other

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0080] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0081] The invention provides an electrostatic precipitator ash hopper maintenance process, which is suitable for the maintenance construction of the electrostatic precipitator ash hopper device. The method of the application can greatly reduce the corresponding cost, further improve the construction efficiency, shorten the construction period, and reduce the construction cost.

[0082] As an embodiment of the present invention, wherein the construction process of this application is as follows figure 1 As shown, the details are as follows:

[0083] Step 1: Check and record the accessories of the electrostatic precipitator;

[0084] After the process is handed over, enter the interior of the electrostatic precipitator through the manhole door in the middle of the electrostatic precipitator, check the condition of each component and make detailed records. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com