Pressure transmitter and manufacturing method thereof

A transmitter and pressure technology, applied in measuring fluid pressure, measuring fluid pressure through electromagnetic components, instruments, etc., can solve problems such as high temperature drift coefficient, low pressure resistance, and easy fatigue deformation of the diaphragm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

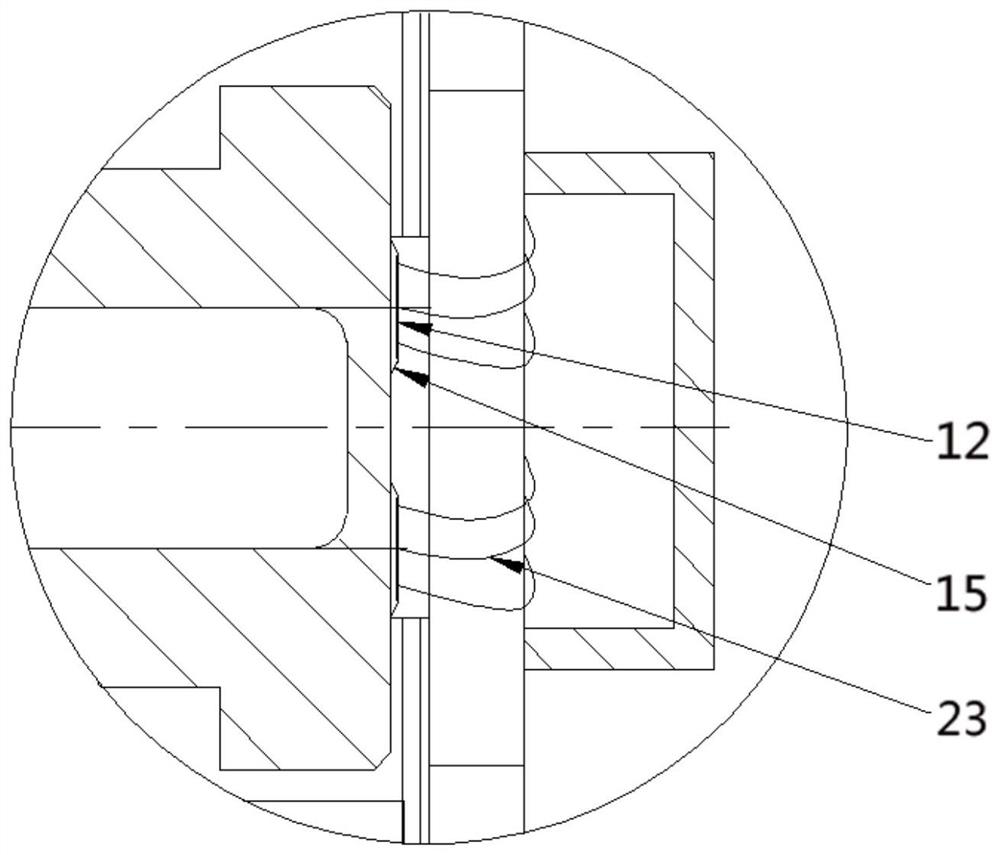

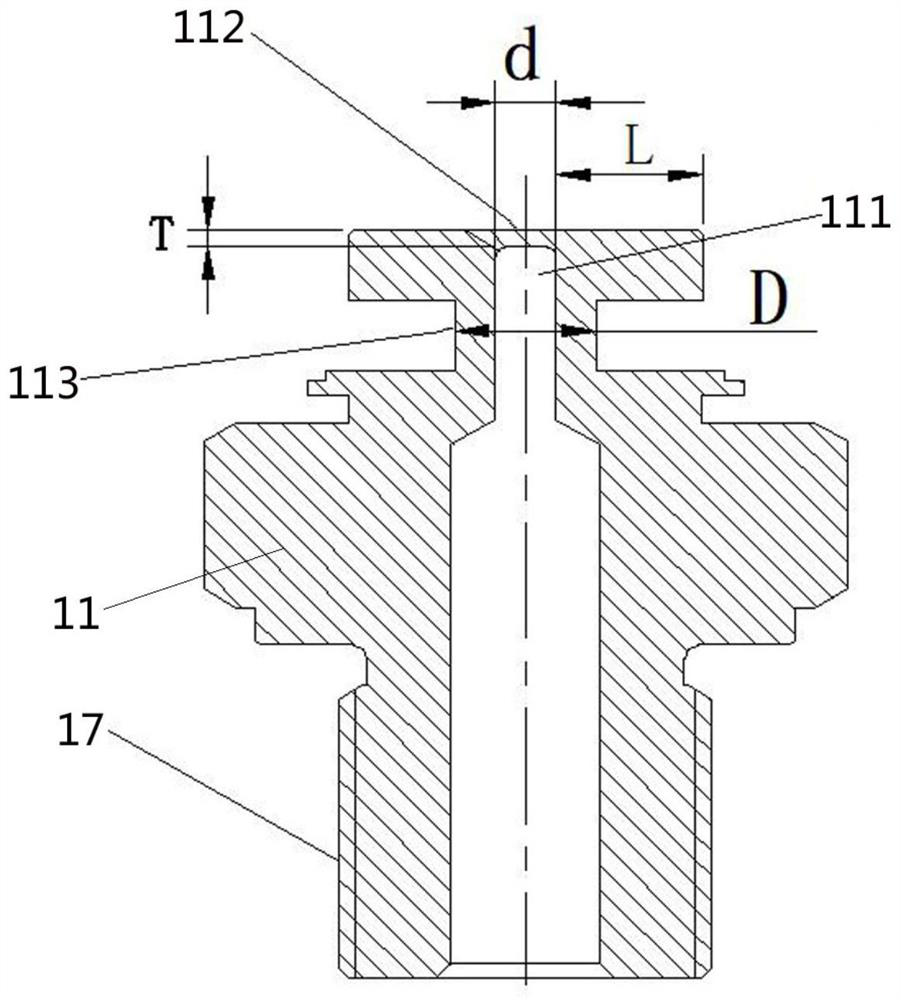

Embodiment Construction

[0046] It should be noted that when a component is referred to as being “fixed on” or “disposed on” another component, it may be directly or indirectly located on the other component. When an element is referred to as being "connected to" another element, it can be directly or indirectly connected to the other element. The terms "upper", "lower", "left", "right", "front", "rear", "vertical", "horizontal", "top", "bottom", "inner", "outer", etc. The indicated orientation or position is based on the orientation or position shown in the drawings, and is only for convenience of description, and should not be understood as a limitation on the technical solution. The terms "first" and "second" are used for convenience of description only, and cannot be understood as indicating or implying relative importance or implicitly specifying the quantity of technical features. "Plurality" means two or more, unless otherwise clearly and specifically defined.

[0047]In order to solve the te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com