Bullet train rod piece measuring device based on artificial intelligence

An artificial intelligence, measuring device technology, applied in the field of rail transit, can solve problems such as unreliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

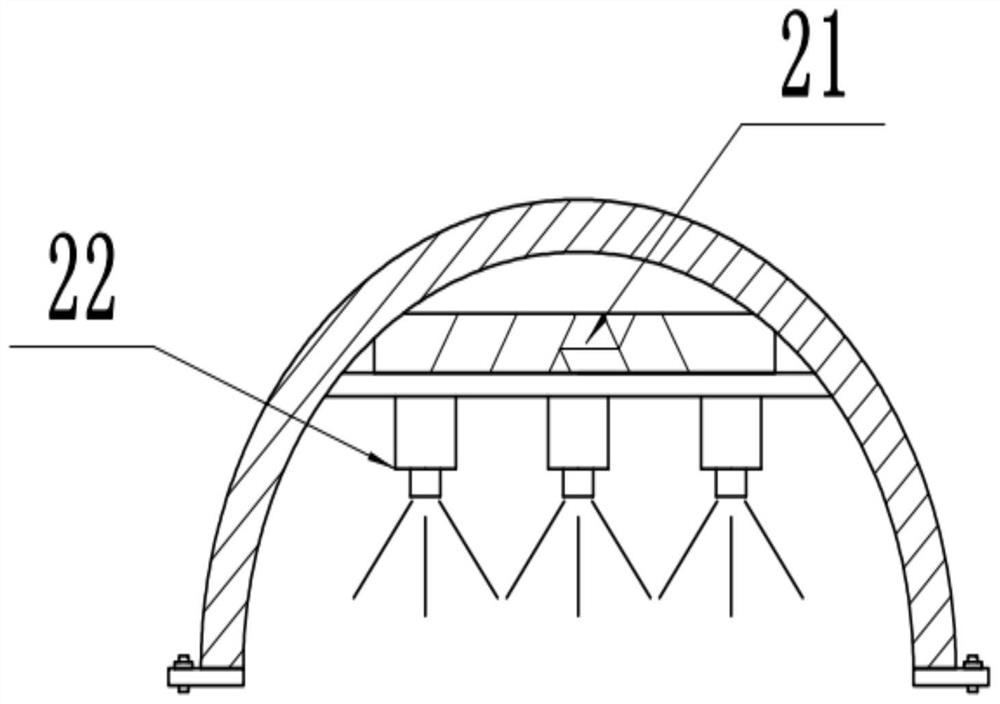

[0020] see Figure 1-4 , an artificial intelligence-based measuring device for motor car rods, including a base 10 and a main control box 14; the base 10 is set as a disc-shaped structure, and the top of the base 10 is fixed with a set of circular structures through three sets of triangularly arranged legs 20 The transmission belt 11, the upper surface of the base 10 located at the center of the transmission belt 11 is fixedly installed with a group of main control boxes 14 integrating signal transmission, analysis, processing and control. On the upper surface of the base 10 at the gap between the front and rear ends of the transmission belt 11 is fixedly placed a waste material receiving groove 12 for collecting the discarded motor vehicle rods. The upper side of the transmission belt 11 is fixedly installed with multiple groups of classified scanning tunnels 13 at equal intervals, and the inner top of the classified scanning tunnels 13 is fixedly installed with a remote sens...

Embodiment 2

[0023] On the basis of Embodiment 1, three groups of equally spaced supporting rotating rods 26 are fixedly installed on the bottom edge of the measuring board, and the bottoms of the supporting rotating rods 26 are rotatably connected in the rotating grooves provided on the upper side of the horizontal plate 24, The support sliding is carried out by rotating the support rotary rod 26 inside the horizontal plate 24, thereby improving the stability of the measuring board when the support bar is measured.

[0024] The working principle of the present invention is: when in use, under the operation of the staff, a large number of motor car rods are placed on the conveyor belt 11 from the front end of the conveyor belt 11 in sequence, and then they are isolated from each other by rubber partitions 31 When passing through the classification scanning tunnel 13, the scanning of the optical mechanical scanning end 22 inside the classification scanning tunnel 13 is analyzed and processed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com