Lime distributing device for concrete pouring

A technology for pouring concrete and ash-sliding pipes is applied in the field of concrete pouring and can solve problems such as affecting the pouring effect and increasing labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

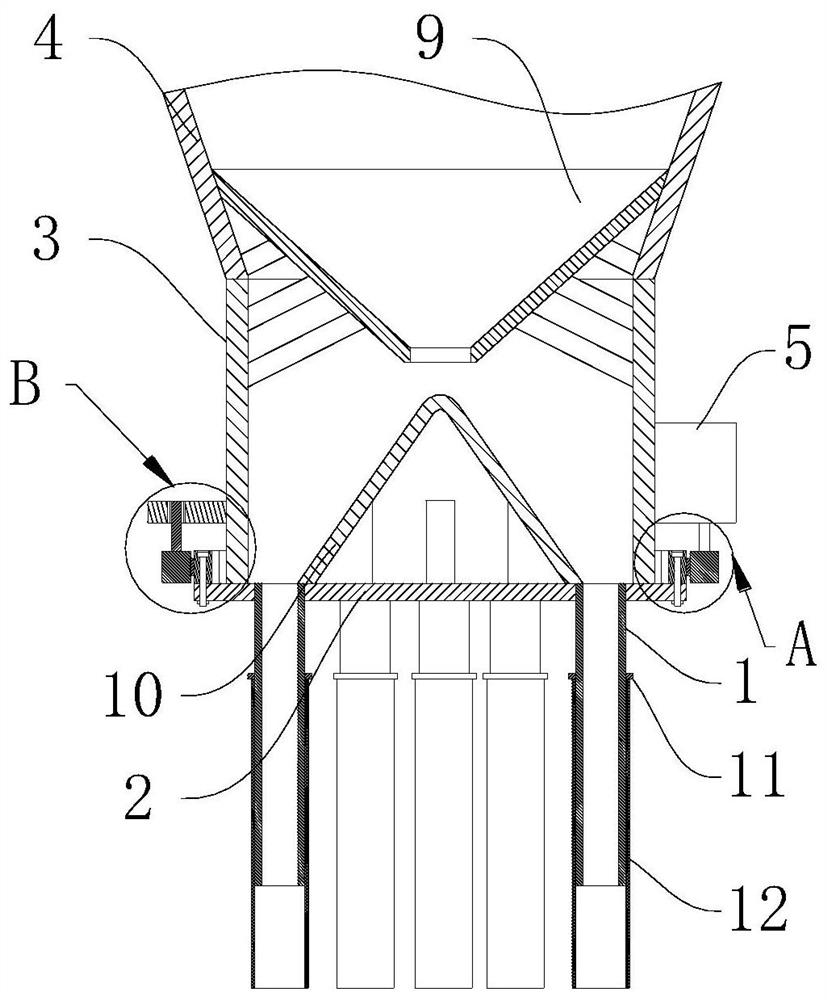

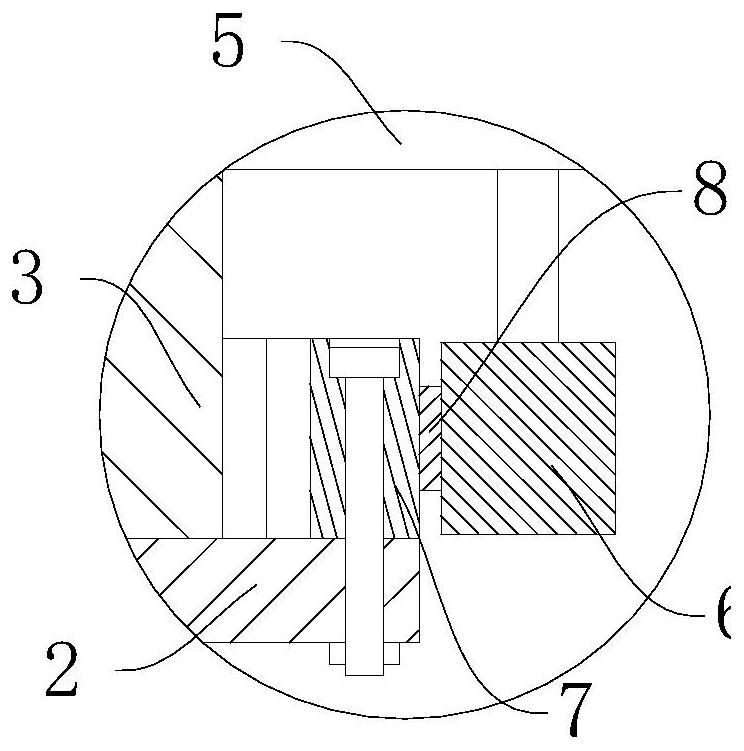

[0035] DETAILED DESCRIPTION OF THE PREFERRED EMBODIMENTS Firstly, the outlet end of the conveying pipe for conveying concrete slurry is placed in the arc-shaped groove of the clamping seat 43, and then the arc-shaped pipe clamp 42 is fixed to the upper end of the supporting seat by bolts, so that the conveying pipe is installed Above the first cone 4, the suspension hole of the suspension plate 44 is hung on the hook of the spreader, and then the ash distributing device is suspended by the spreader, and the ash distributing device is transferred to the top of the pouring port, and then at least four Move one ash chucking pipe 1 down into the pouring port. At this time, at least four ash chucking pipes 1 are between the circular limit template and the circular wall, and then rotate the moving ring 11 because the moving ring 11 is threaded with the ash chucking pipe 1 Therefore, the moving ring 11 rotates while moving the moving ring 11 up and down along the ash chucking pipe 1, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com