Thermoplastic package cooling and shaping workpiece conveying slideway

A technology for cooling and shaping and conveying slides, which is applied in packaging, slideway, transportation and packaging, etc., and can solve the problems of inability to buffer workpieces, inability to assist in accepting items, and inability to assist in pushing items to slide and convey quickly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0026] Examples:

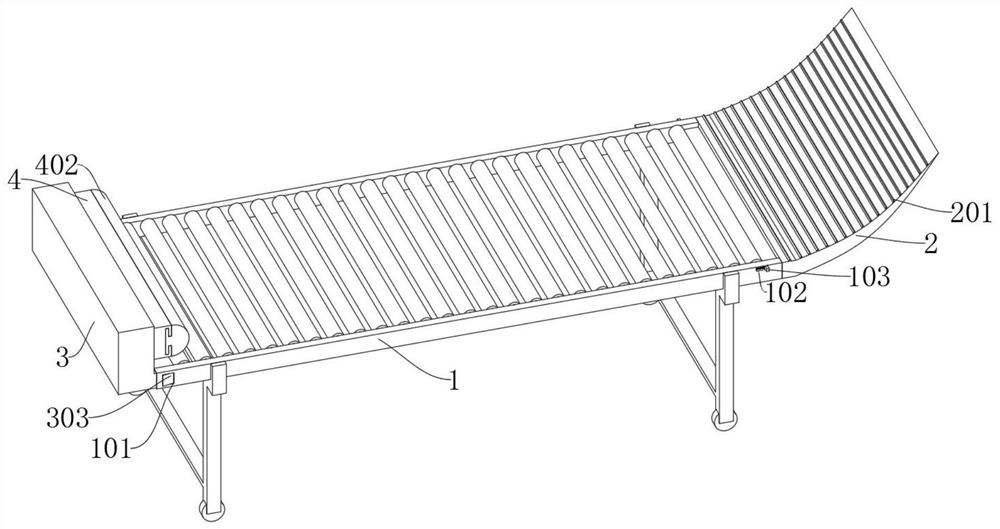

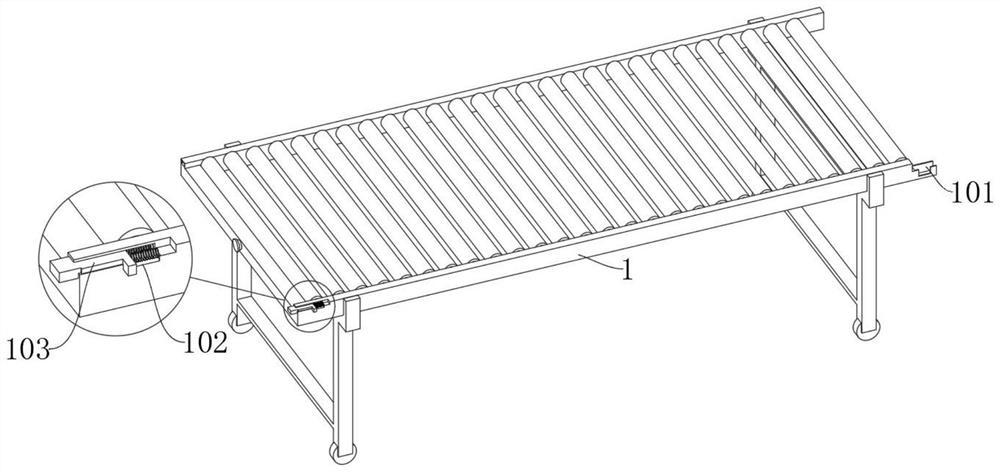

[0027] As attached figure 1 Attached Figure 5 Shown:

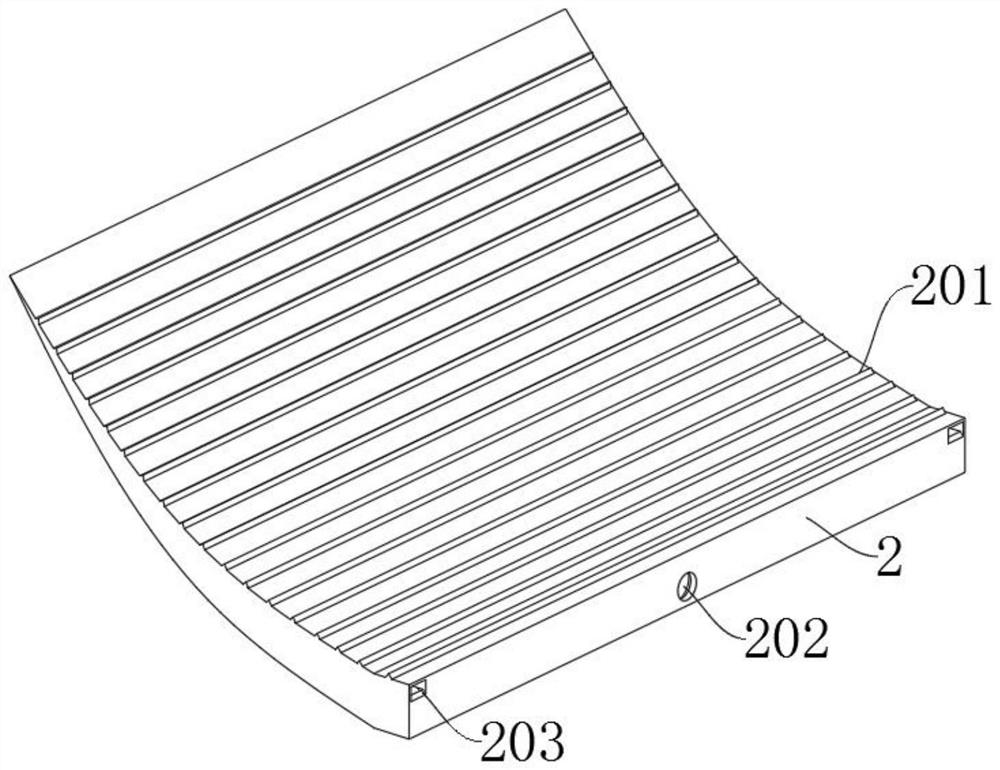

[0028] The present invention provides a thermoplastic packaging cooling and shaping workpiece conveying slide, which includes a main body 1, a deflector 2, a connecting piece 3 and a moving block 4. The main body 1 is the conveying slide body, and the bottom of the main body 1 is equipped with moving wheels, And the center of the right end of the main body 1 is provided with a rotating head with a central convex cylindrical structure, and the mounting groove 102 is used to install the limit block 103 through a spring, so that the limit block 103 can be moved by the spring to make the flow guide When the plate 2 is used in rotation, the limit block 103 can be inserted into the fixing groove 203 so that the deflector 2 can be fixed and cannot rotate; the deflector 2 is installed at the right end of the main body 1, and the deflector 2 rotates The slot 202 is embedded and installed with the rotating head of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com