Atomization system and control method thereof

A technology of atomization system and control method, which can be applied to spray devices, liquid spray devices, etc., and can solve the problems of liquid leakage, peculiar smell, mixed smell atomizer, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

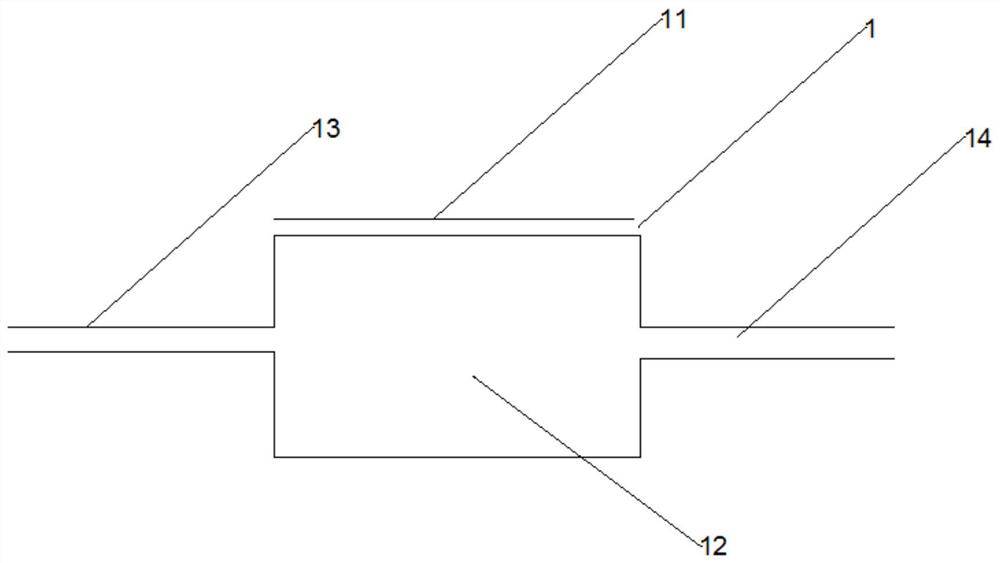

[0033] Specifically, such as Figure 1~3 As shown, an atomization system, the atomization system 1 includes an atomization sheet 11 and an atomization pool 12, the atomization sheet 11 can atomize the liquid or foam in the atomization pool 12, the The atomization tank 12 is provided with an inlet 13 , an outlet 14 and an atomization port, and the atomization sheet 11 is arranged on the atomization port, that is, the atomization sheet 11 is not arranged on the outlet 14 .

[0034] Preferably, the atomizing sheet 11 is a microporous piezoelectric vibrating sheet.

[0035] Further, external liquid and / or gas can enter the atomization pool 12 from the inlet 13, and the liquid and / or gas in the atomization pool 12 can be discharged from the atomization pool through the outlet 14 12.

[0036] Further, the inlet 13 of the atomization pool 12 is connected to the liquid bottle, and the liquid in the liquid bottle can be transported into the atomization pool 12 in a liquid or foam sta...

Embodiment 2

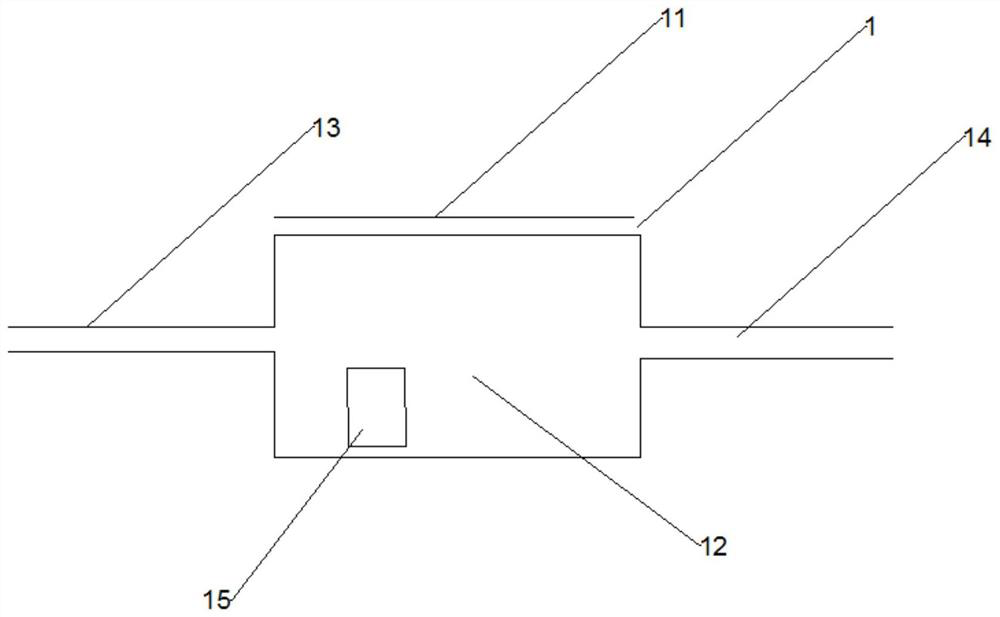

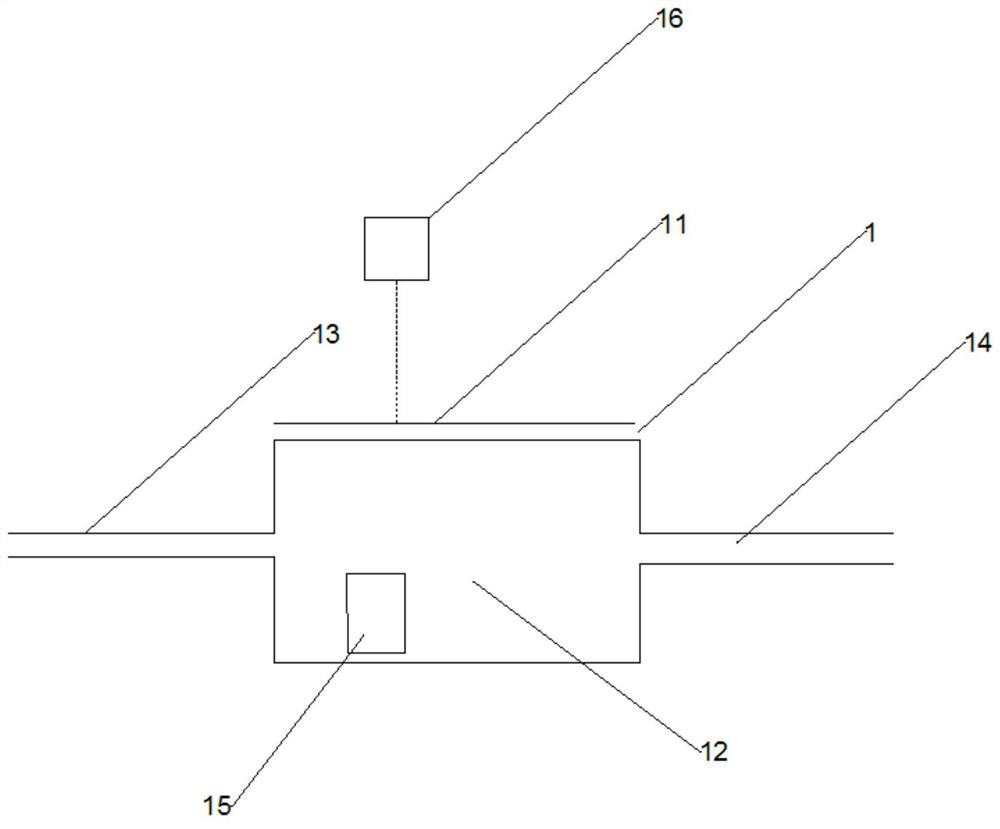

[0055] Specifically, such as Figure 1~3 As shown, an atomization system, the atomization system 1 includes an atomization sheet 11 and an atomization pool 12, and the atomization pool 12 is provided with an inlet 13 and an outlet 14.

[0056] Further, the atomization system 1 further includes a sensor, the sensor includes an in-pool sensor 15 located in the atomization pool 12, and the in-pool sensor 15 is configured to detect the liquid in the atomization pool 12 .

[0057] Furthermore, the sensor also includes an outside sensor 16 located outside the atomization pool 12 , and the outside sensor 16 is configured to detect the air outside the atomization pool 12 .

[0058] Preferably, the sensor 15 in the pool can detect the liquid level and properties of the liquid in the atomization pool 12, and the properties of the liquid include but not limited to the viscosity, temperature, surface tension, etc. of the liquid; the sensor 15 in the pool includes But not limited to visc...

Embodiment 3

[0060] Such as Figure 4 As shown, the present invention also provides a control method of an atomization system, the atomization system is used in the above-mentioned atomization system 1, and the control method includes:

[0061] Step S1: the sensor 15 in the tank detects the liquid level in the atomization tank 12;

[0062] Step S2: Determine whether the liquid level in the atomization pool 12 is less than the set value; if yes, determine that the liquid volume in the atomization pool 12 is too low, transport liquid into the atomization pool 12, and continue to execute step S1; if not , it is determined that the liquid volume in the atomization pool 12 is sufficient, the atomization sheet 11 starts to work, and proceeds to step S3;

[0063] Step S3: The sensor 15 in the pool detects the properties of the liquid in the atomization pool 12;

[0064] Step S4: Control the vibration frequency of the atomizing sheet 11 according to the properties of the liquid in the pool.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com