An integrated treatment method for river channel regulation silt cleaning and debris separation

A treatment method and sludge technology, applied in separation methods, chemical instruments and methods, filtration separation, etc., can solve the problems of low work load of impurity removal structure, single structure of impurities removal by dredging device, high degree of sludge adhesion and volume, etc. , to achieve the effect of increasing the workload of dredging, avoiding inability to absorb or absorbing stagnation, and reducing working hours

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

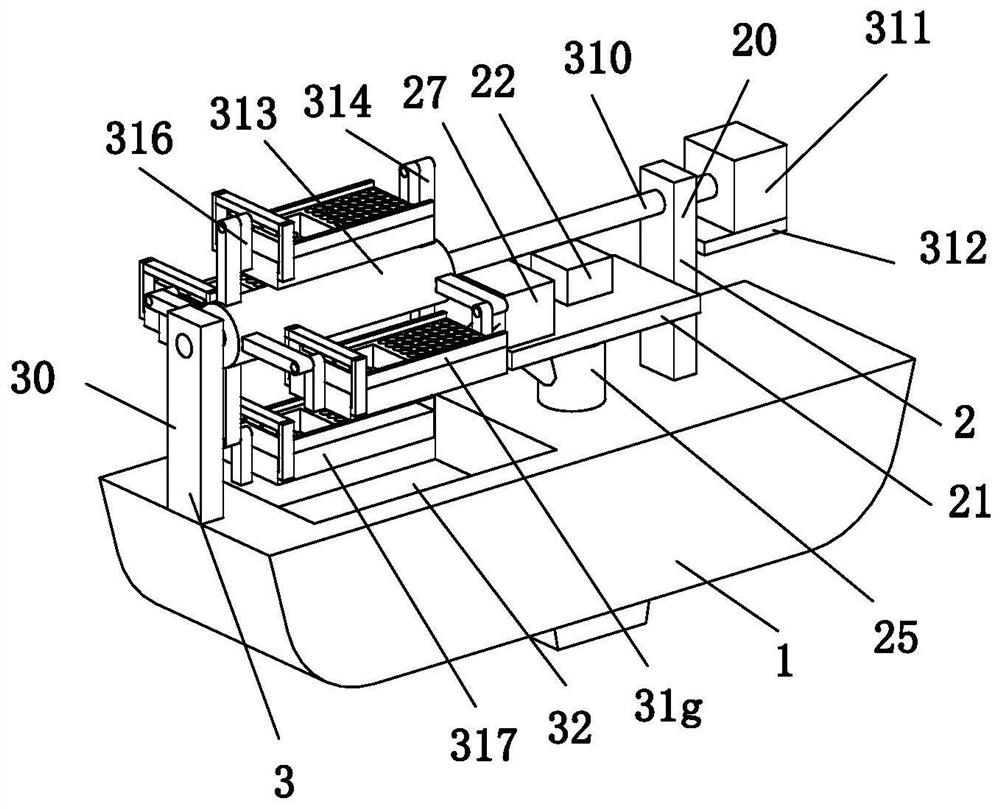

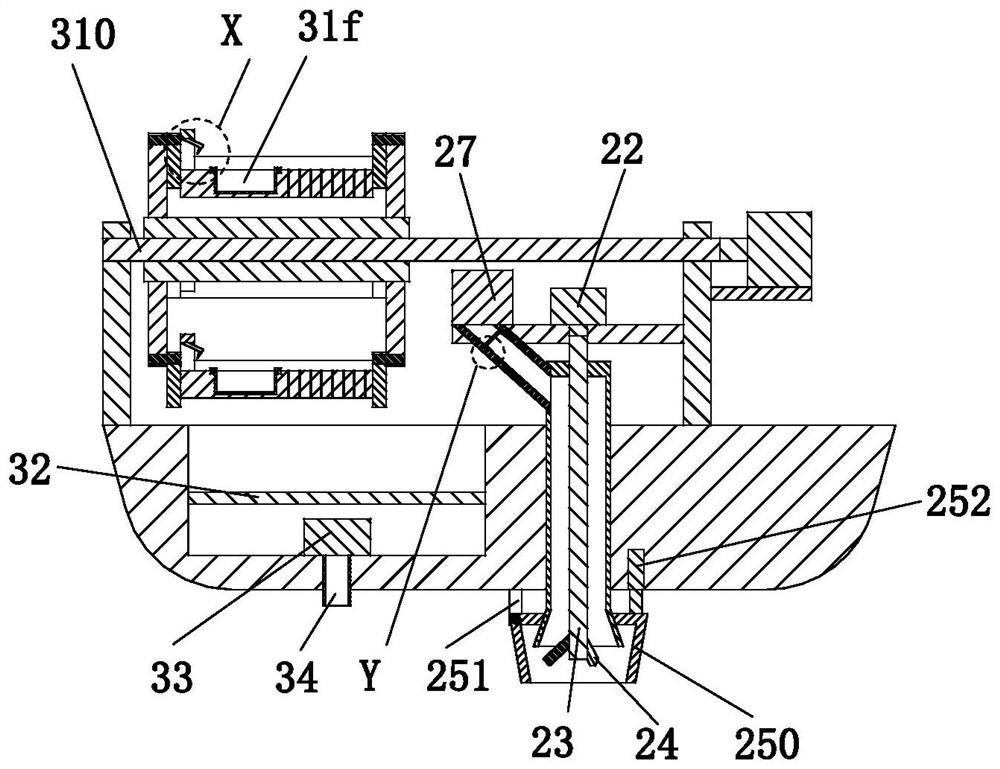

[0033] The embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, but the present invention can be implemented in many different ways that are predetermined and covered by the claims.

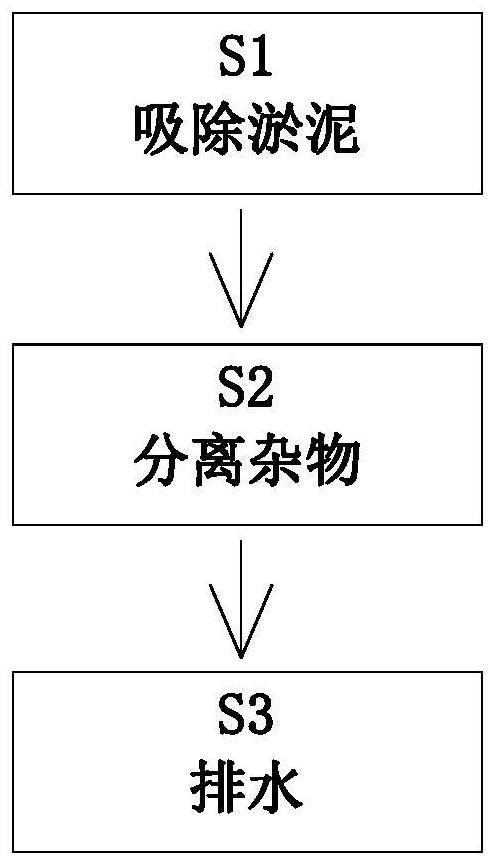

[0034] Such as Figure 1 to Figure 7 As shown, an integrated processing method of sludge cleaning and debris separation for river channel governance uses a river channel governance sludge cleaning and debris separation integrated processing device, and the river channel governance sludge cleaning and debris separation integrated processing device includes The motorized hull 1, the mud suction mechanism 2 and the separation group 3 use the above-mentioned integrated processing device for river channel regulation sludge cleaning and debris separation to carry out river channel regulation sludge cleaning and debris separation integrated treatment. The specific treatment methods are as follows:

[0035] S1. Suction of silt: When the mot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com