Smooth iron plate surface flatness nondestructive testing device and method

A technology for surface flatness, non-destructive testing, applied in measuring devices, instruments, scientific instruments, etc., can solve problems such as low testing efficiency, bad products entering the market, dazzling errors, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

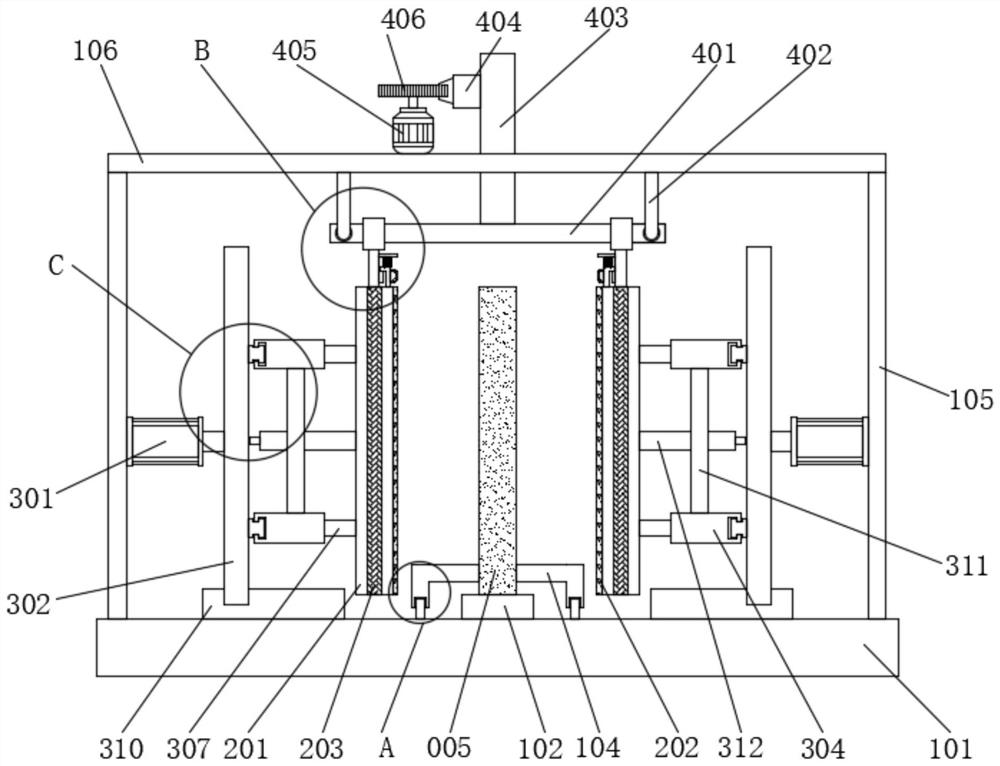

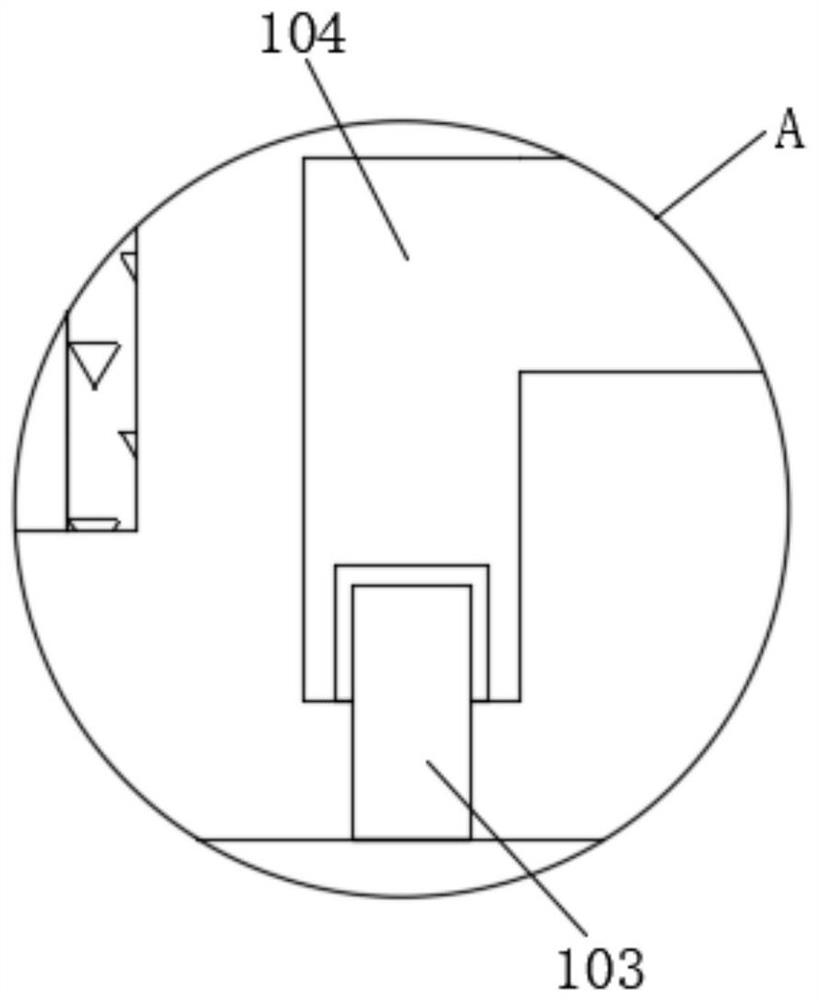

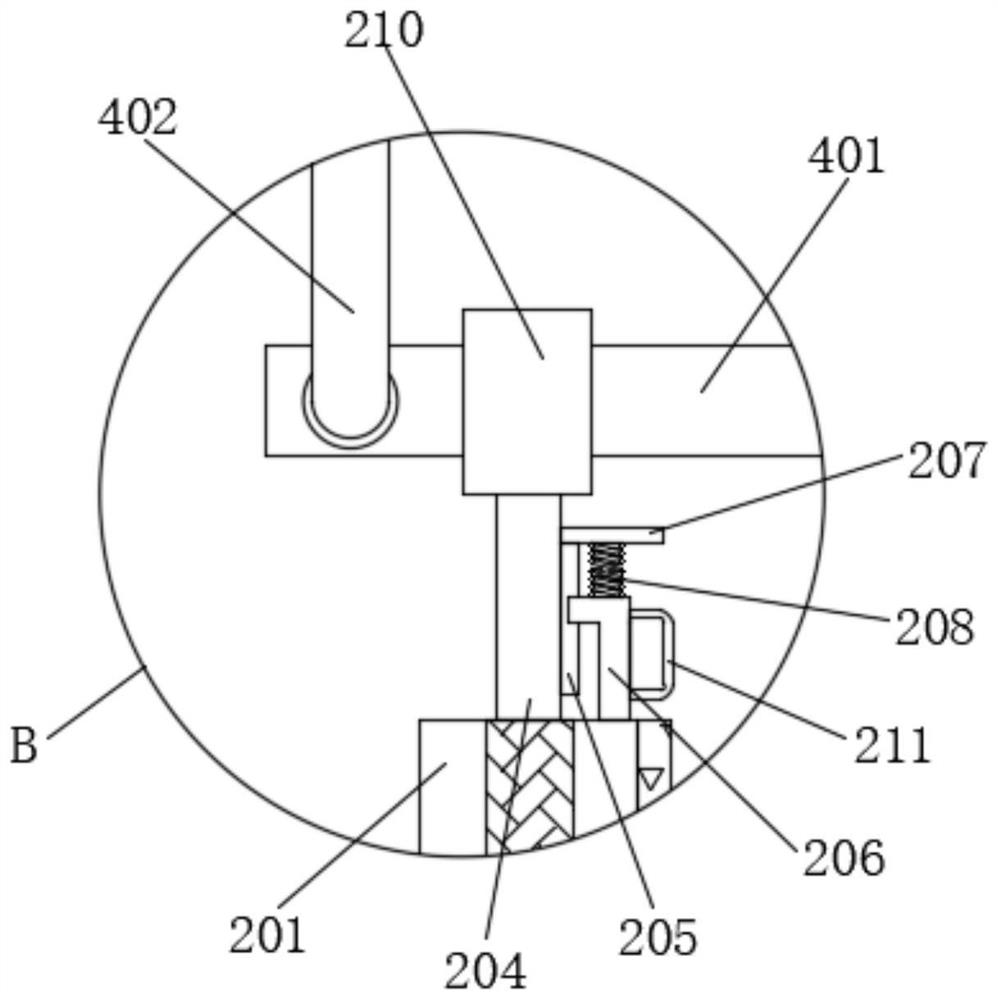

[0051] see Figure 1-3 and Figure 5-6 , a non-destructive testing device for smooth iron surface flatness, comprising a support positioning mechanism, a detection mechanism, a level adjustment mechanism, a forward drive mechanism and an iron plate to be tested 005, the support positioning mechanism includes a device base 101, and the middle part of the top of the device base 101 is fixed An electromagnet 102 is connected, and both sides of the electromagnet 102 are provided with a slide rail 103 fixedly connected to the top of the device base 101. The top of the slide rail 103 is slidably connected with a positioning plate 104, and the positioning plate 104 is set in an L shape. The plate 005 is placed on the top of the electromagnet 102, and the ends of the two positioning plates 104 away from the device base 101 are respectively attached to the two sides of the iron plate 005 to be tested. It is convenient to position and fix the iron plate 005 to be tested, and after the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com