Air fryer with multiple cavities

An air fryer, multi-cavity technology, applied in kitchen utensils, home utensils, roasters/barbecue grids, etc., can solve problems such as rising costs, complex internal structures, and long time consumption, and achieve manufacturing cost control. , the effect of shortening working time and shortening cooking time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

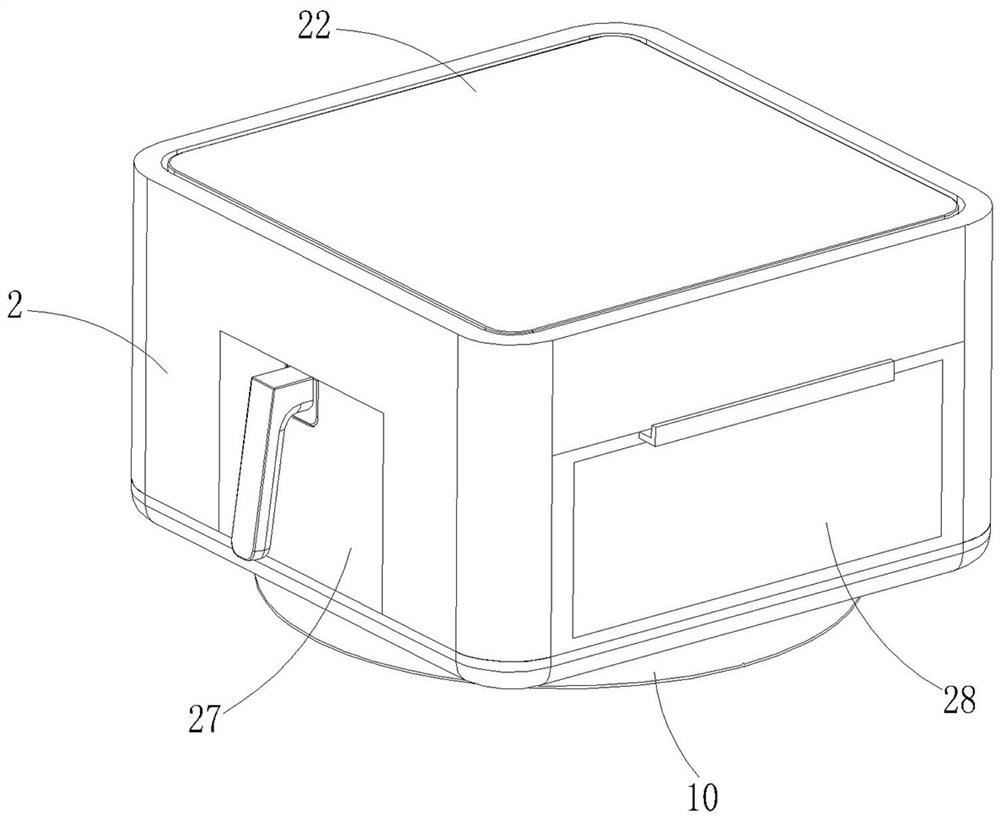

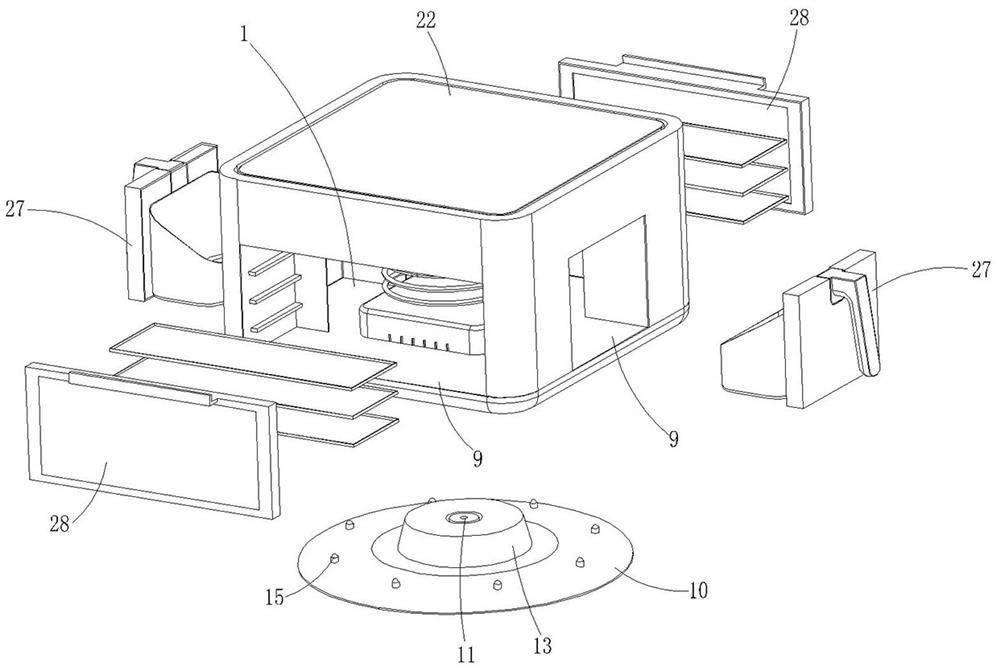

[0037] refer to Figure 1 to Figure 10 , a multi-cavity air fryer, including a fryer body 2 with an inner cavity 1, a frying container assembly, a heating assembly arranged in the fryer body 2, and a control circuit assembly ( not shown in the figure), the inner chamber 1 is divided into an installation chamber 3 and several heating chambers 4, the installation chamber 3 communicates with each heating chamber 4, and each heating chamber 4 is arranged around the installation chamber 3 on the outer peripheral side;

[0038] The heating assembly includes a motor 5, a hot air vane 6 arranged in the installation cavity 3 and driven by the motor 5, and a heating pipe assembly 7 vertically arranged in the installation cavity 3, and the hot air vane 6 includes The blade base 7 arranged horizontally, and the guide part 8 formed by extending ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com