Self-locking multi-cavity hydraulic oil cylinder and implementation method thereof

A hydraulic cylinder and fixed-type technology, applied in the direction of fluid pressure actuators, etc., can solve the problems of easy leakage and no self-locking structure, etc., and achieve the effects of flexible use, high precision and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

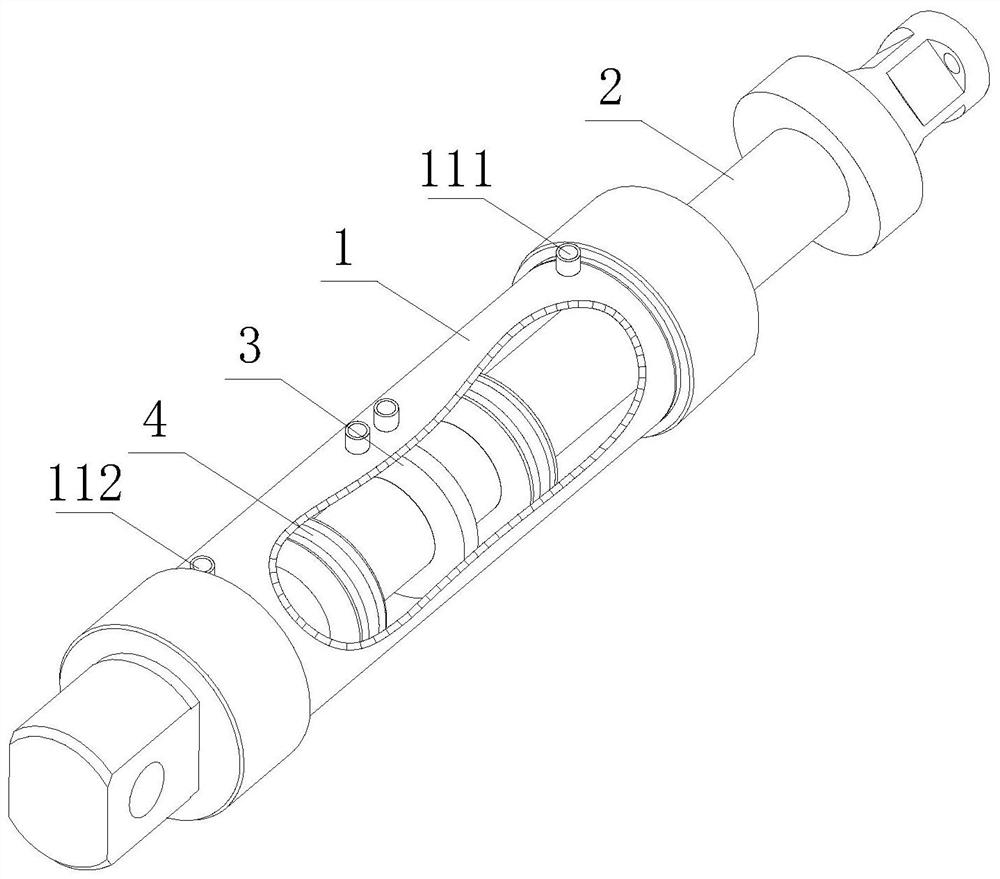

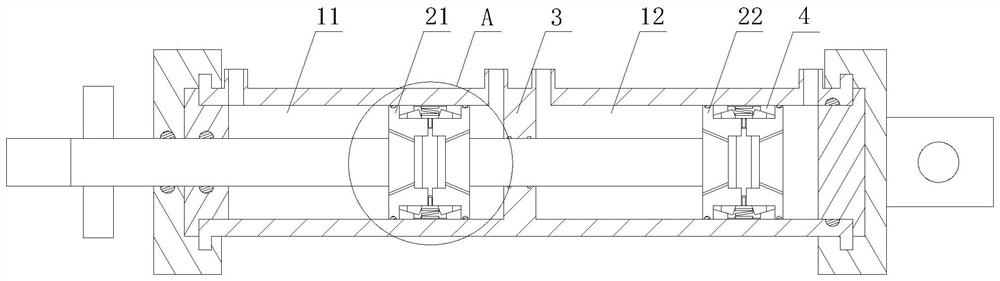

[0033] see Figure 1-Figure 2 , a self-locking multi-chamber hydraulic cylinder, including a cylinder body 1 and a piston rod 2, the two ends of the cylinder body 1 are respectively provided with a first cavity 11 and a second cavity 12, the first cavity 11 and the second cavity The two ends of the body 12 are respectively connected with a front oil port 111 and a rear oil port 112, the front oil port 111 and the rear oil port 112 are used for oil in and out, and a partition plate is arranged between the first cavity 11 and the second cavity 12 3. The partition plate 3 is used to separate the first cavity 11 and the second cavity 12. The piston rod 2 runs through the cylinder body 1, the piston rod 2 runs through the first cavity 11 and the second cavity 12, and the piston rod 2 The first piston 21 and the second piston 22 are respectively connected to the positions of the first cavity 11 and the second cavity 12, and the first piston 21 and the second piston 22 are connected ...

Embodiment approach

[0035] In order to better demonstrate the implementation process of the self-locking multi-chamber hydraulic cylinder, this embodiment now proposes an implementation method of the self-locking multi-chamber hydraulic cylinder, including the following steps:

[0036] Step 1: The central groove 2111 is filled with internal oil body. When oil enters the front oil port 111 or the rear oil port 112 of the first cavity 11 and the second cavity 12 at the same time, the external oil body enters the first oil passage 2112 , and push the isolation plug 2113 to move the position, squeezing the inner oil body in the center groove 2111;

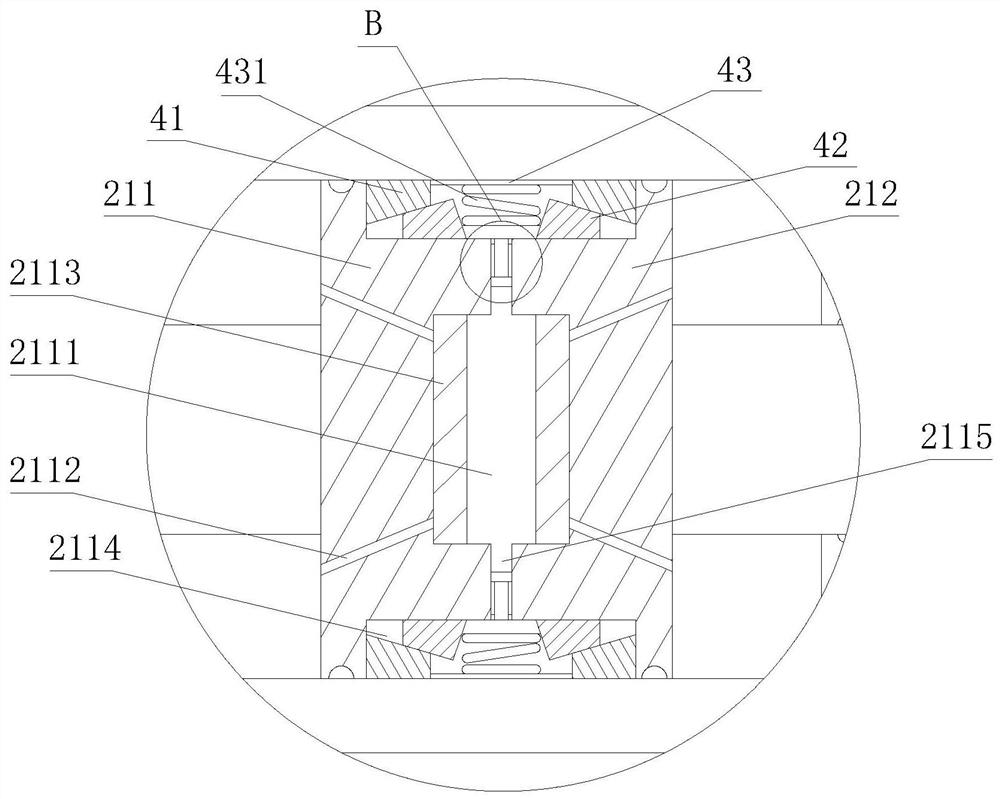

[0037] Step 2: The inner oil body flows under pressure, enters from the second oil passage 2115, pushes the moving position of the sealing block 4322, the guide post 4321 pushes the limit block 432 to move into the side wall groove 2114, and the locking spring 431 shrinks;

[0038] Step 3: The first locking ring 41 and the second locking ring 42 spread ap...

Embodiment 2

[0041] see Figure 7-Figure 9 , a self-locking multi-chamber hydraulic cylinder, comprising a cylinder body 1 and a piston rod 2, the two ends of the cylinder body 1 are respectively provided with a first cavity 11 and a second cavity 12, and the cylinder body 1 is penetrated with a piston rod 2 , the piston rod 2 runs through the first cavity 11 and the second cavity 12, and the piston rod 2 is placed in the position of the first cavity 11 and the second cavity 12 and connected with the first piston 21 and the second piston 22 respectively, A second locking device 5 is provided between the first cavity 11 and the second cavity 12, and a side wall groove 2114 is opened on the inner side of the second locking device 5, and the first locking ring 41 and the second locking ring 41 are installed in the side wall groove 2114. A locking ring 42, a fixed ring 43 is arranged between the first locking ring 41 and the second locking ring 42, and a locking spring 431 is equidistantly con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com