Tower type sand making unit

A tower-type and mobile technology, applied in the field of tower-type sand making units, can solve the problems of not being able to meet the demand for the same sand and gravel, high energy consumption, and inability to increase the speed and frequency of the main engine.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

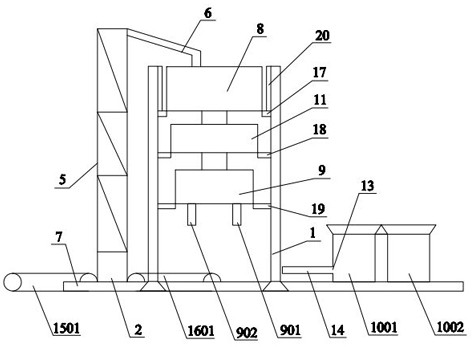

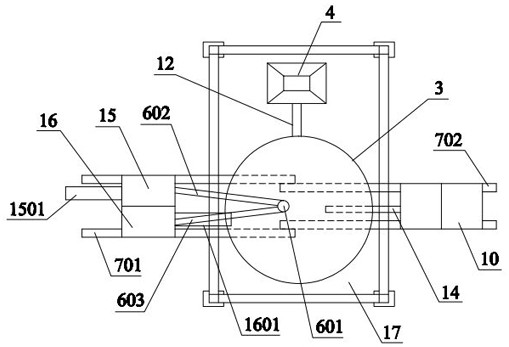

[0020] The embodiment of the present invention will be described in detail in conjunction with the accompanying drawings. This embodiment is based on the technical solution of the present invention, and provides detailed implementation and specific operation process, but the scope of protection of the present invention is not limited to the following embodiments.

[0021] As shown in the accompanying drawings, a building-type sand making unit includes a multi-layer vertical steel structure support frame 1 and a PLC control system. The steel structure support frame 1 is equipped with a mobile feeding mechanism 2 , the steel structure support frame 1 is provided with a crushing and screening mechanism 3 and a dust collection mechanism 4, the PLC control system is arranged on one side of the steel structure support frame 1, and is connected with the mobile feeding mechanism 2. The crushing and screening mechanism 3 and the dust collection mechanism 4 are electrically connected; th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com