Vehicle automatic intelligent spraying system

A vehicle automation and intelligent technology, applied in the direction of spraying device, etc., can solve the problems of working space pollution, low spraying efficiency and low precision, and achieve the effect of ensuring spraying efficiency and spraying precision, improving spraying efficiency and high positioning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

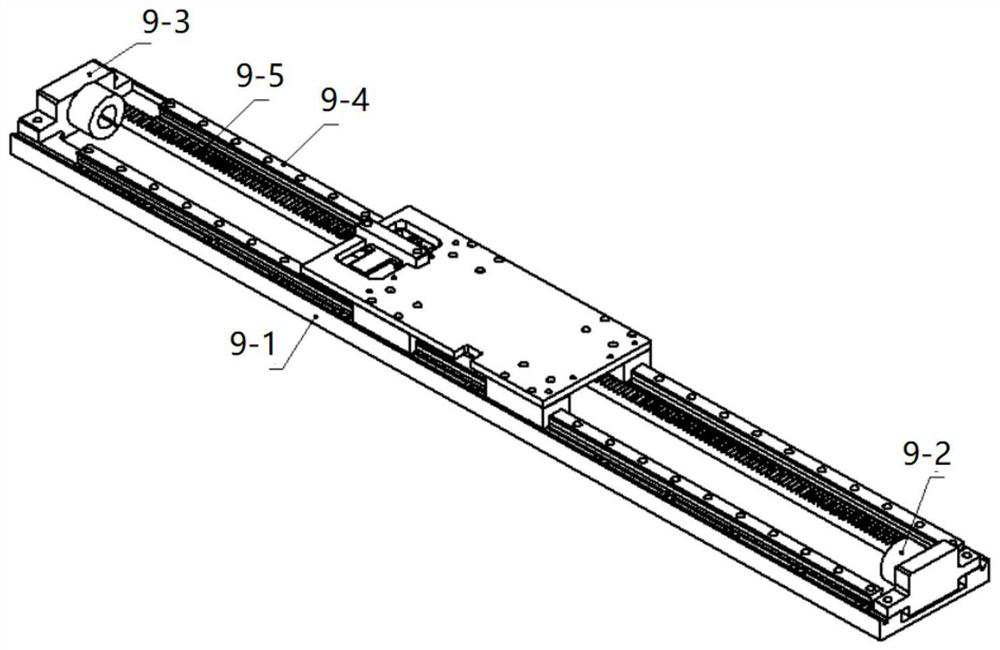

Image

Examples

Embodiment 1

[0081] Embodiment 1 The automatic intelligent coating system for vehicles of the present invention can realize left and right double-station spraying by using two cantilevered five-axis linkage spraying structures, see Figure 12 As shown, to further improve the spraying efficiency of the vehicle, it is possible to realize the automatic and precise spraying of multi-color patterns on the surface of the vehicle without masking and overspray.

[0082] In particular, the present invention can change the equipment stroke of the cantilever five-axis linkage spraying structure according to the size of the spraying workpiece and in combination with the cost of the spraying equipment.

[0083] Figure 13 It is a traditional spraying effect, it is continuous, but the loss is large, the spraying pattern needs to be manually blocked by the spraying, the efficiency is low, it is harmful to the health, it is not environmentally friendly, and the degree of automation is not high. However, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com