System and method for testing dynamic modulus of viscoelastic material

A dynamic modulus, testing system technology, applied in the direction of analyzing materials, testing material strength by applying stable tension/compression, measuring devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

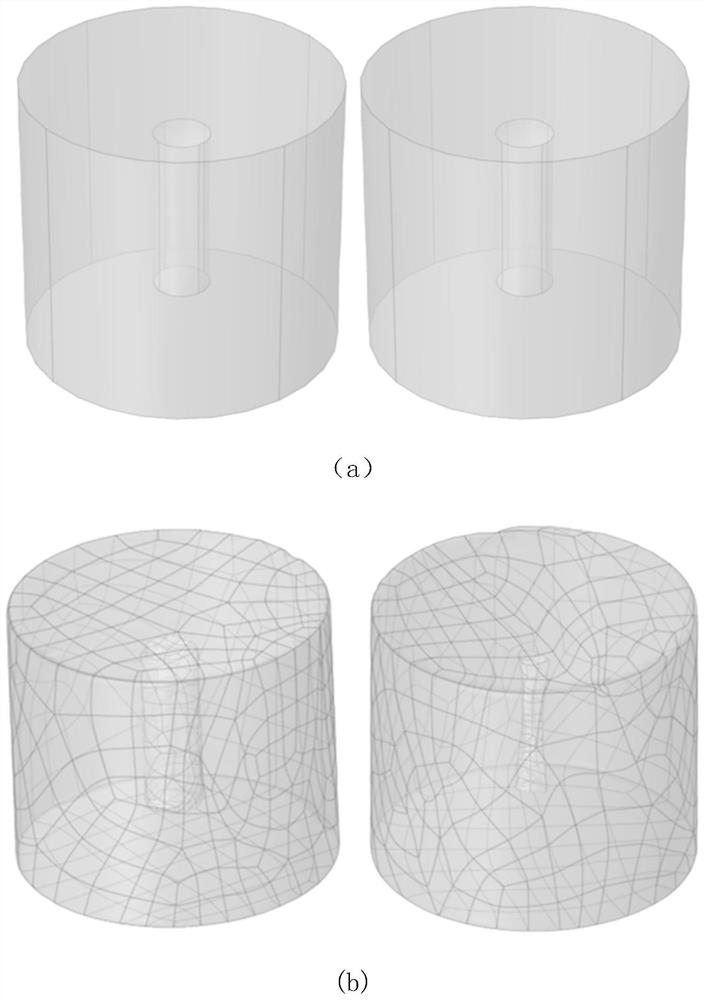

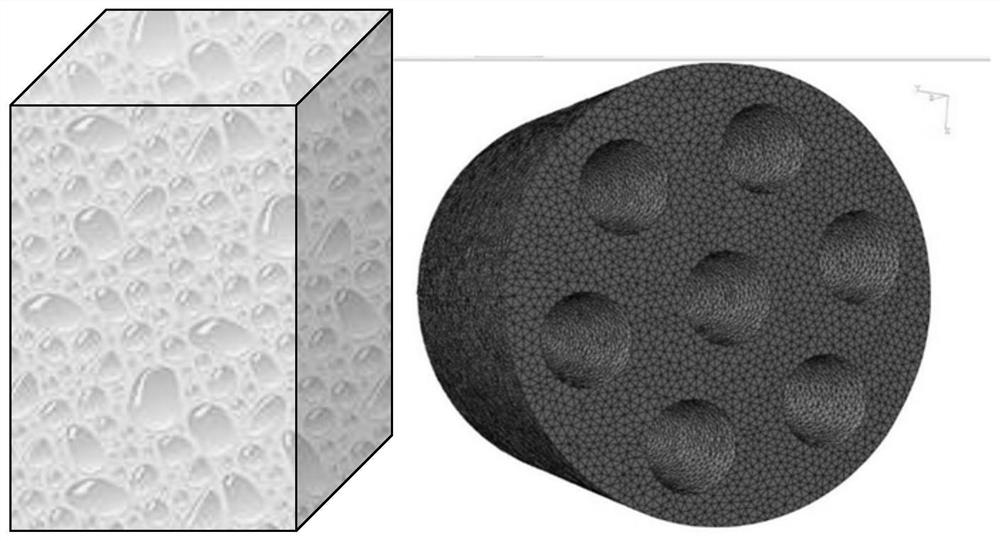

[0077] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0078] The viscoelastic material dynamic modulus testing system of the present invention can realize the automatic measurement of the viscoelastic material dynamic modulus within the temperature and pressure range that can be controlled by itself. On this basis, by using the complex model based on the H-N model in the material parameter inversion module The volume model is used to fit C1 and C2 in the WLF equation, and finally can complete the simulation of extreme environmental conditions such as actual high hydrostatic pressure, and measure the dynamic parameters of viscoelastic materials with wide frequency and wide temperature range.

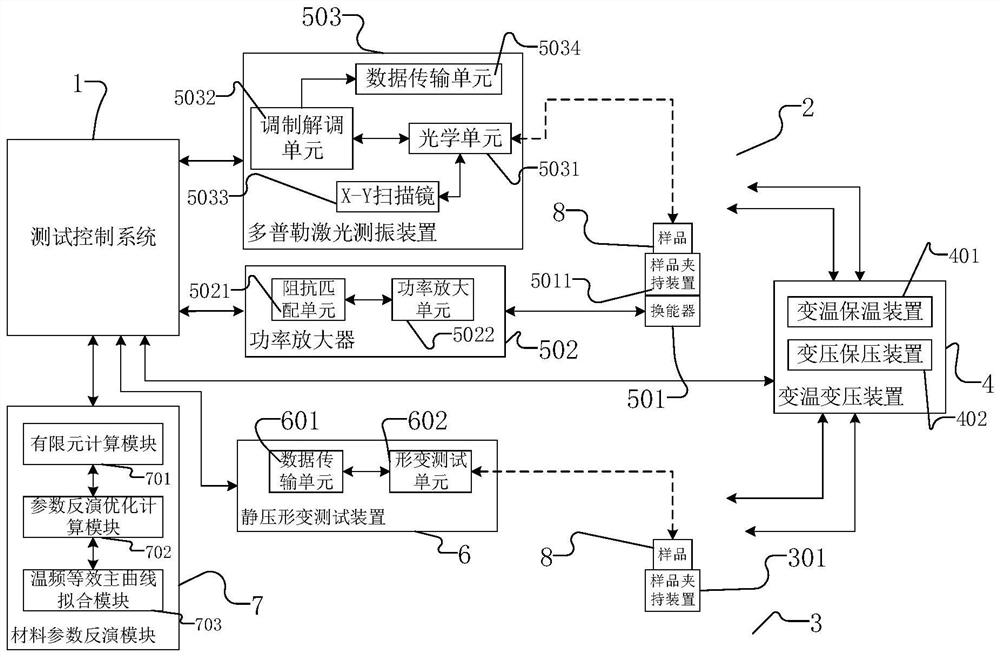

[0079] Such as image 3 As shown, the viscoelastic material dynamic modulus testing system test control system 1 of the present invention, the first variable temperature variable pressure environment simulat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com