Panel detection system and method

A panel detection and panel technology, which is applied in general control systems, control/regulation systems, and testing optical properties, etc., can solve the problems of fixed number of panels, fixed detection functions, troublesome wearing of dust-free clothes, etc., to reduce The effect of labor cost, easy management and easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

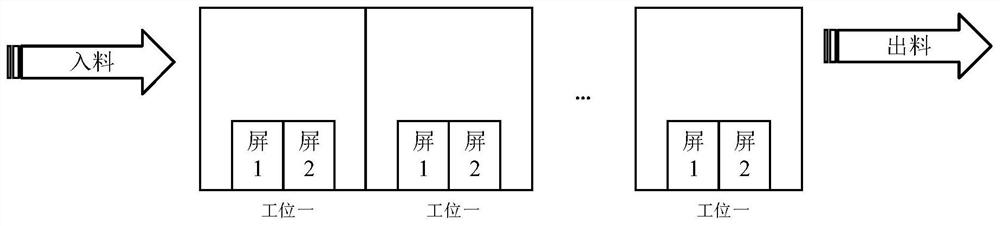

[0073] figure 1 It is a schematic diagram of a linear structure provided by an embodiment of the present invention, that is, a structural design diagram of a linear detection station, such as figure 1 As shown, the linear detection station in the figure includes multiple detection stations. The station in the figure refers to multiple detection stations, and each station is provided with two carriers, and each carrier has a The panels to be tested, screen 1 and screen 2 refer to different panels to be tested on the two carriers.

[0074] In this embodiment, during the panel inspection production process of the LCS system, the panel enters the machine from the feeding place to prepare for inspection. If the inspection station is designed with multiple inspection stations, and each inspection station has the same inspection function , then the panel can randomly enter any idle station for detection, and notify the PLC system to move the panel out of the machine after the detect...

Embodiment 2

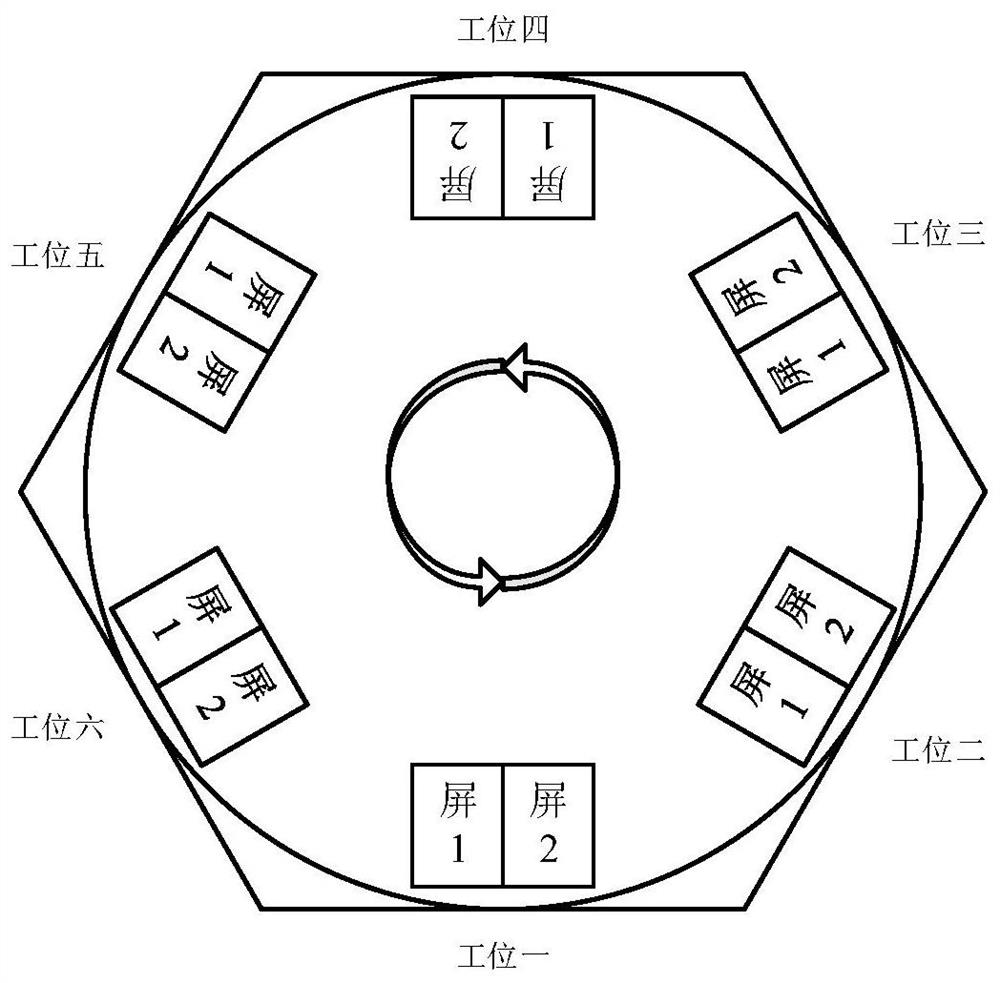

[0076] figure 2 It is a schematic diagram of the turntable structure provided by the embodiment of the present invention, that is, a structural design diagram of the turntable detection station, as shown in figure 2 As shown, the six-station turntable detection station in the figure includes a plurality of detection stations, and the station one, station two...station six in the figure means that the detection station has six detection stations, and Each station is provided with two carriers, and each carrier is placed with a panel to be tested. Screen 1 and screen 2 refer to different panels to be tested on the two carriers.

[0077] In this embodiment, the LCS system is in the production process of panel inspection, because the design of the machine may be a turntable structure, the panel is fed from one of the inspection stations for inspection, and the inspection process can be executed at the feeding station, each The detection function of the detection station can be ...

Embodiment 3

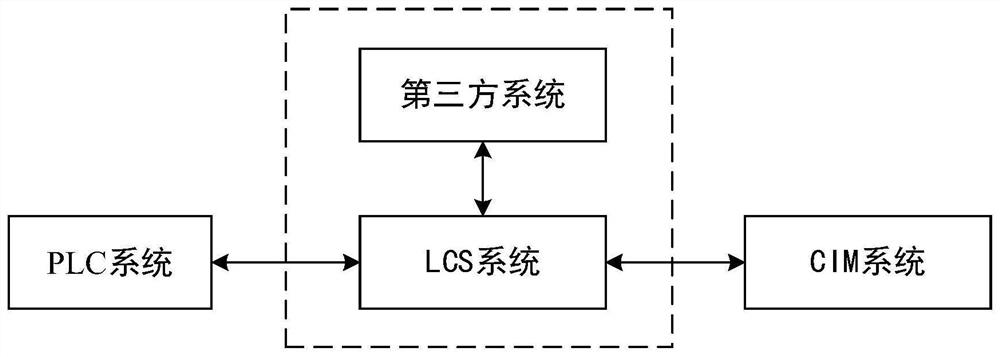

[0079] image 3 It is a system architecture provided by an embodiment of the present invention. In this embodiment, the panel detection system also includes a CIM system; the LCS system is also used for data backup and / or reporting to the CIM system of required detection information. The LCS system can provide the client's CIM system posting function. After the panel inspection is completed, the client's CIM system needs to collect all the inspection defects and inspection results of the panel. At this time, the LCS needs to collect all the required information and report it when the inspection is completed. Some information may come from The PLC system provides, and some information may come from third-party software. The LCS system needs to obtain this information according to the relevant agreement, and report it to the CIM system after summarizing.

[0080] In the process of automatic detection generation, the PLC system starts to obtain panel information when the panel arri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com