Fluid pipeline bypass structure

A fluid pipeline and fluid tube technology, applied in the field of temperature control equipment auxiliary devices, can solve the problems of response lag, fatigue loss, and inability to sense fluid pressure in real time, and achieve accurate reflection, adjustment of opening, and improvement of timeliness of response Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

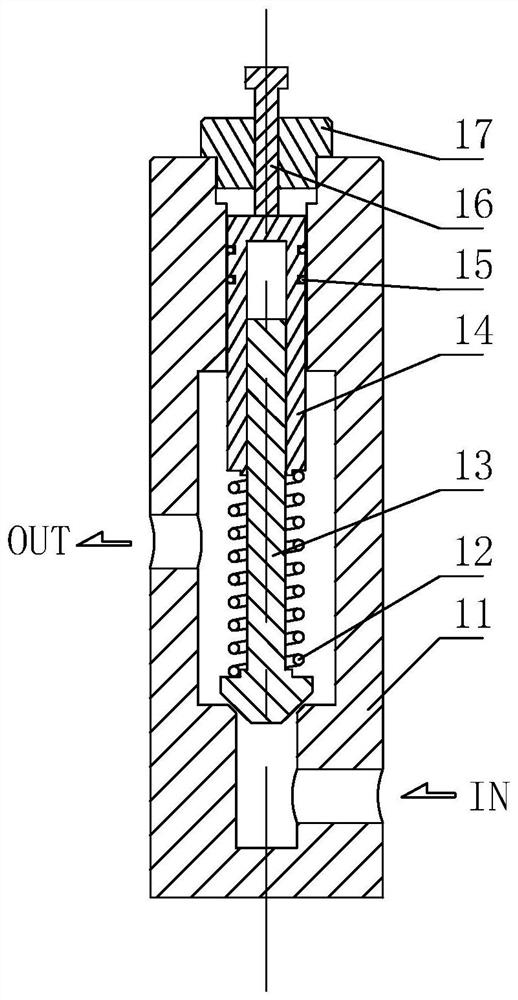

[0023] The utility model will be described in detail below in conjunction with the accompanying drawings. The description in this part is only exemplary and explanatory, and should not have any limiting effect on the protection scope of the present invention.

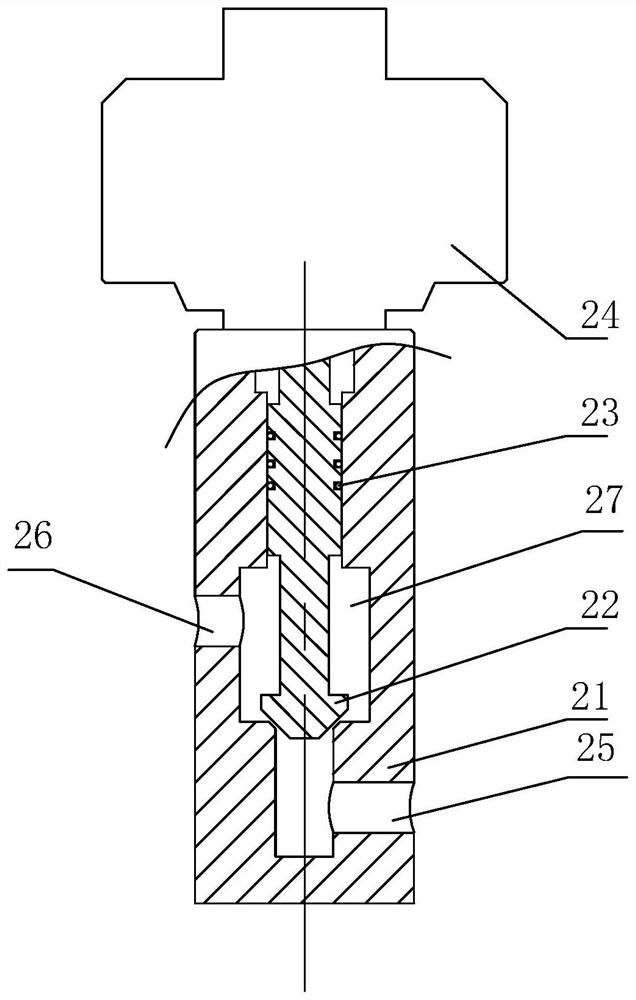

[0024] The present invention provides a fluid pipeline bypass structure, including a bypass structure main body 21 and a fluid pipeline structure;

[0025] The main body 21 of the bypass structure is connected in the fluid pipeline structure;

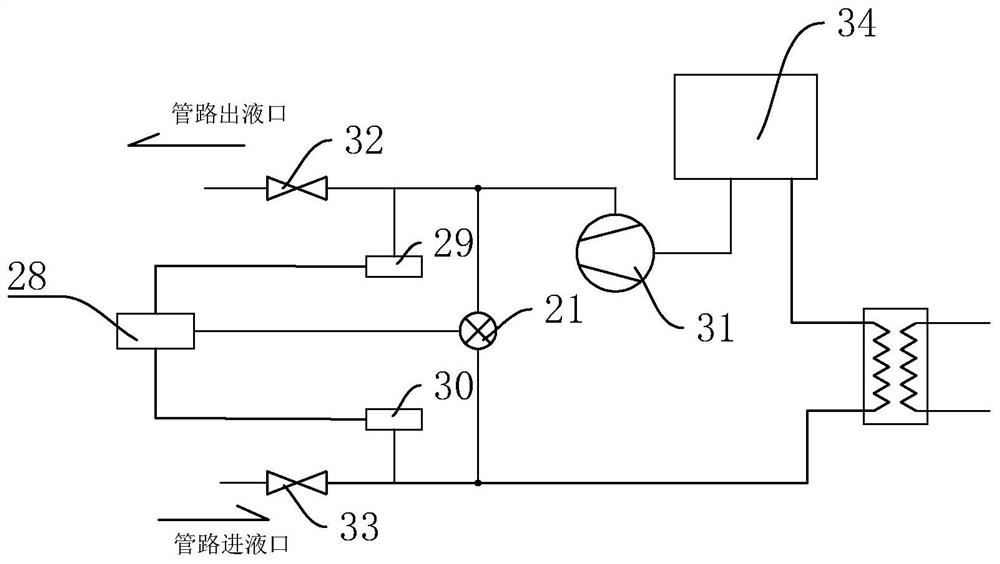

[0026] The fluid pipeline structure includes a second ball valve 33 and a first ball valve 32 arranged at the pipeline liquid inlet and pipeline liquid outlet; it is arranged between the first ball valve 32 and the bypass structure main body 21 The first pressure sensor 29; the second pressure sensor 30 arranged between the second ball valve 33 and the bypass structure main body 21; and the first pressure sensor 29, the second pressure sensor 30, the bypass structure The main bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com