Structure of hard sealing gasket

A kind of hard sealing and gasket technology, which is applied in the direction of engine sealing, sleeve/socket connection, pipe/pipe joint/pipe fitting, etc. It can solve the problems of prominent sealing problems and the inability of the sealing structure to ensure normal operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

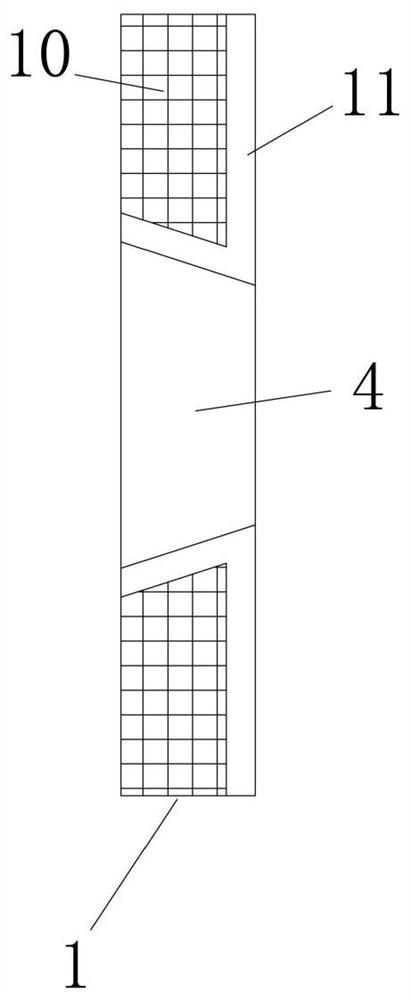

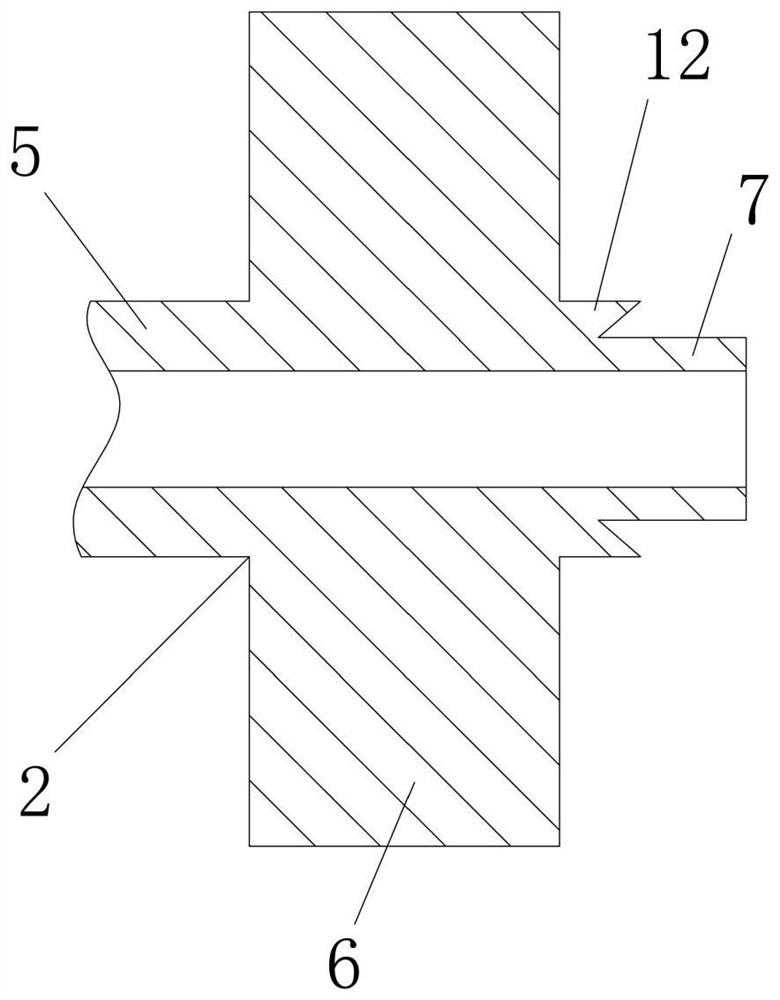

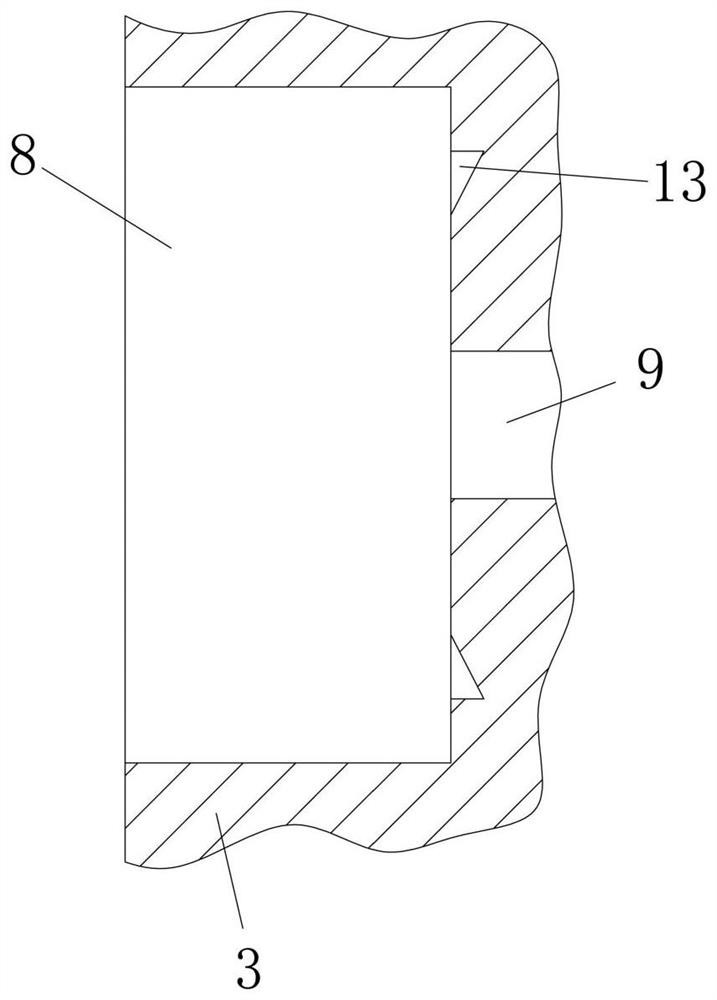

[0037] Embodiment: the structure of a kind of hard gasket, as Figure 1-Figure 20 As shown, it includes a sealing gasket, a male end tube and a female end tube. The sealing gasket is in the shape of a disc, and a middle hole is provided at the center of the sealing gasket. The male end tube includes a left end tube, a middle end tube and a right end tube. tube, the outer diameter of the middle end pipe is larger than the left end pipe and the right end pipe, the female end pipe is provided with a large inner hole and a small inner hole, the large inner hole and the small inner hole are coaxial, and the large inner hole The inner end plane of the inner end plane is perpendicular to the axis of the large inner hole, the right end pipe is arranged in the small inner hole, the middle end pipe is arranged in the large inner hole, and the gasket includes a rubber layer and a metal layer, so The outer diameter of the gasket is matched with the inner diameter of the large inner hole, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Overall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com