Method of Controlling Transport Vehicles for Transporting Sliver Cans in a Spinning Mill and a Transport Vehicle for Performing the Method

A technology for spinning mills and vehicles, applied in program control, manufacturing tools, transportation and packaging, etc., can solve problems such as large size of carriage, undiscovered non-circular spray tube, uneconomical control method, etc., to achieve large The effect of flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

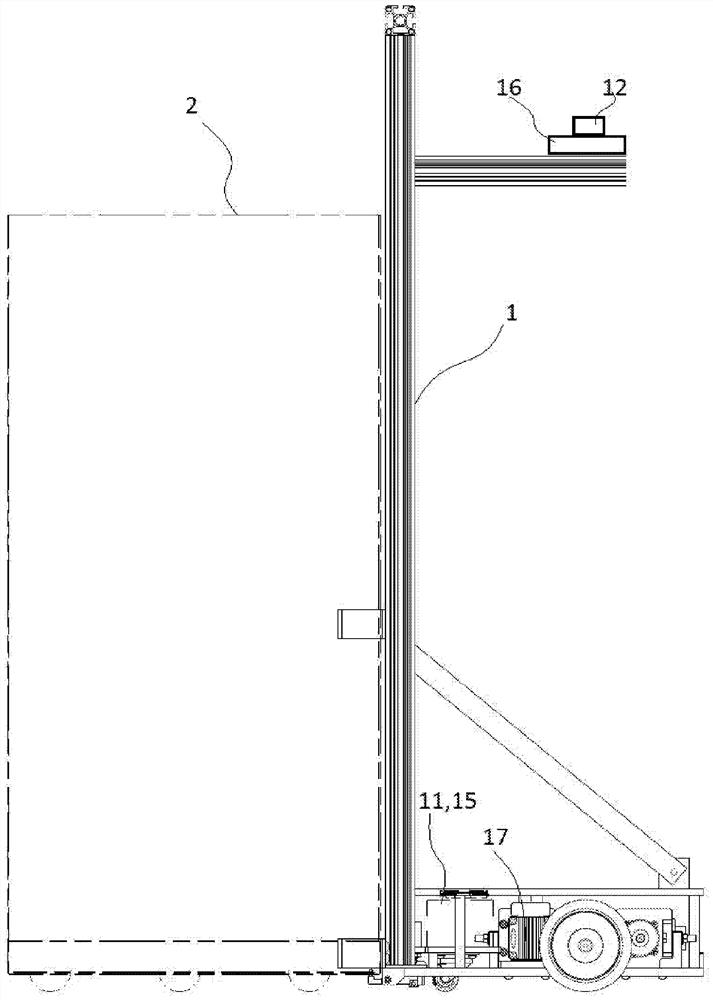

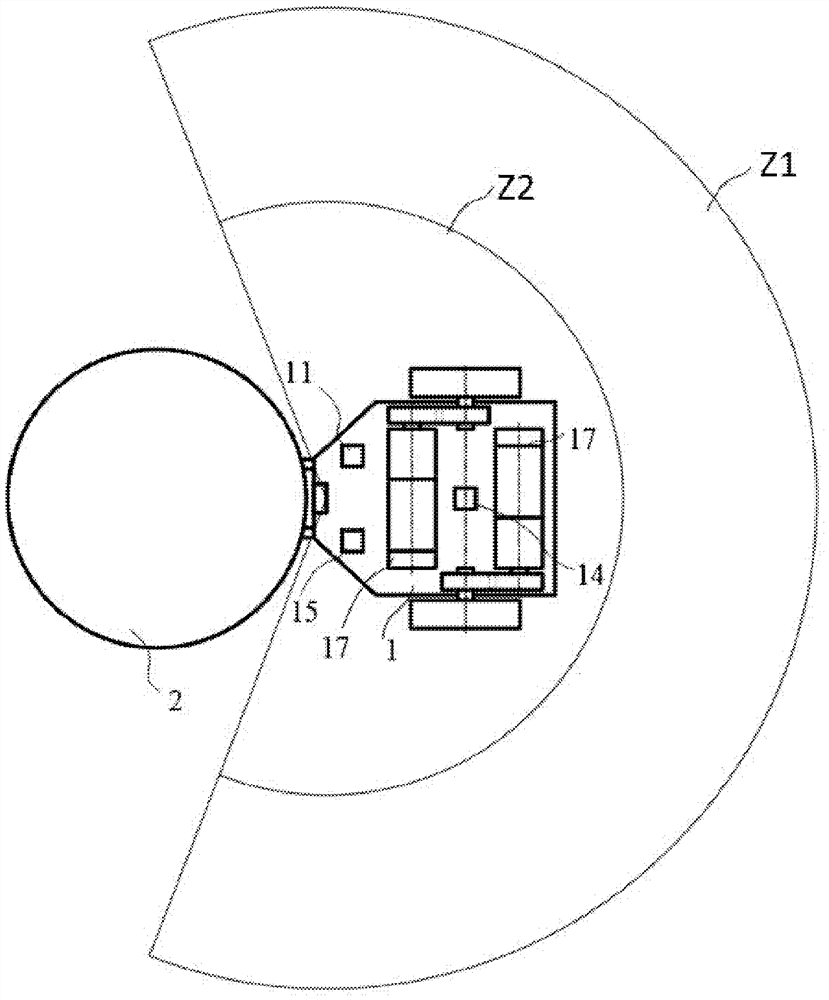

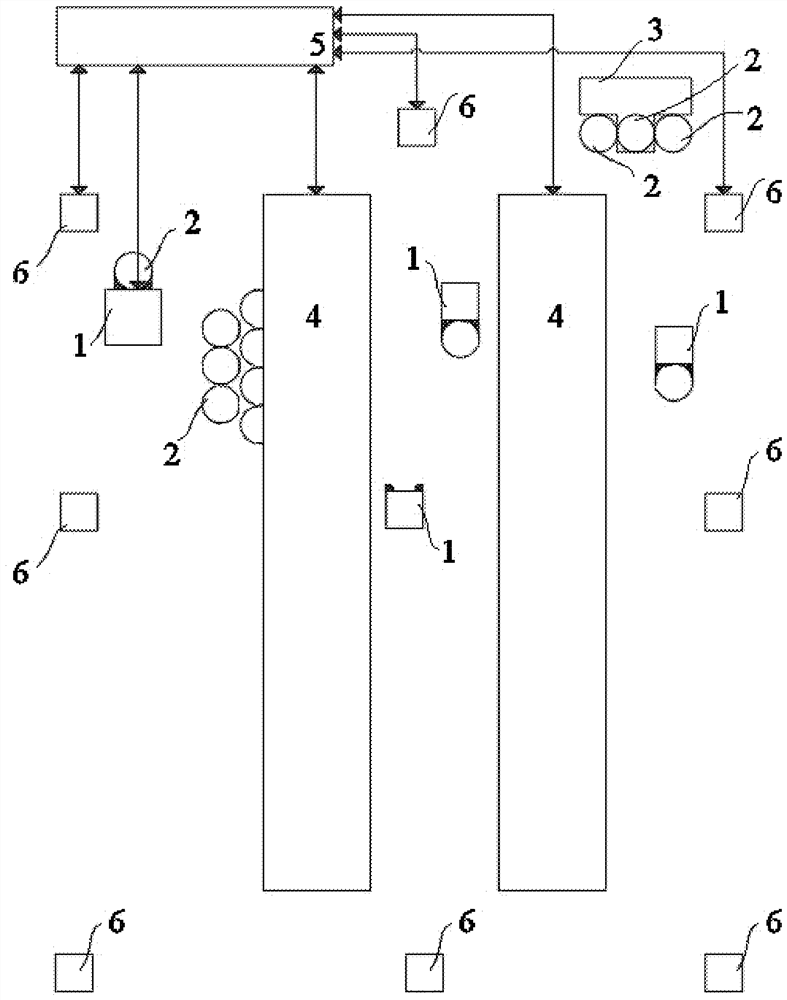

[0028] A method for controlling a transport vehicle 1 used in a spinning mill between a filling station 3 for filling sliver into drums 2 and The cans 2 are transported between the can working positions 2 at the workstations of the spinning machine 4, which spinning mill comprises at least one filling station 3 in which the sliver is deposited in the cans 2 in a known manner. The filling station 3 is connected to one or more preparatory machines, such as cards, combers or wire-drawing machines, as well as a storage device for empty cans 2 and a storage device for full cans 2 . Each bobbin 2 in a spinning mill is assigned a unique identifier which is inseparably connected to the bobbin and which can be easily read by filling stations and transport vehicles. When filling the cartridges 2 with sliver, the amount of sliver deposited in the cartridge 2 is monitored, and after filling is complete, each filled cartridge 2 is dispensed with the amount of sliver deposited in the cartri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com