Feeder comprising two groups of paper transferring suction nozzles

A paper transfer and paper nozzle technology, applied in the field of feeder that includes two sets of paper transfer suction nozzles, can solve the problems of poor paper feeding ability and mismatched paper separation speed, and achieve the effect of increasing working speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

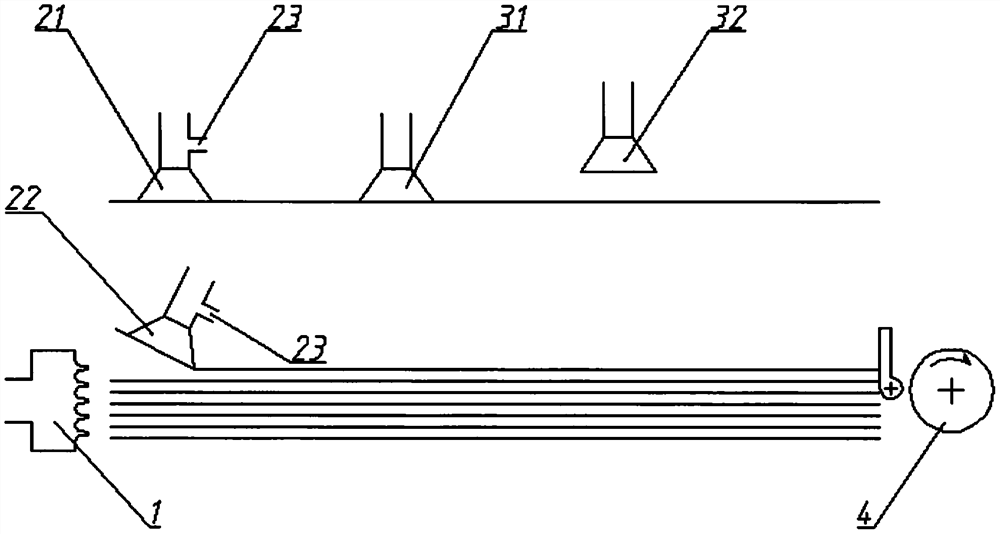

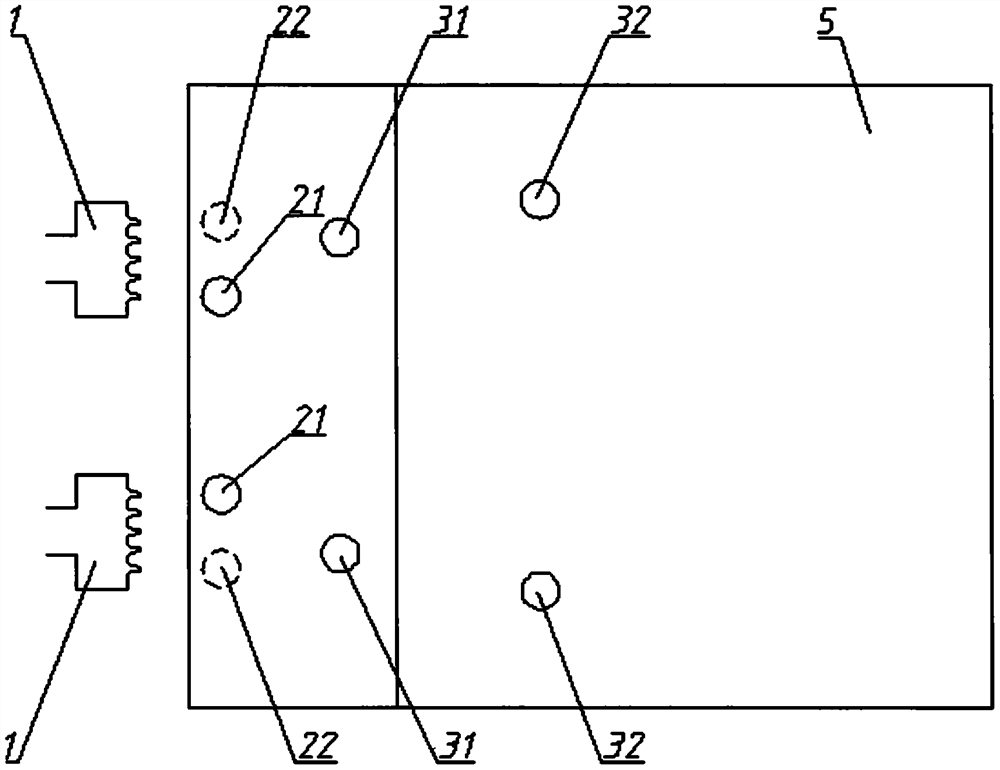

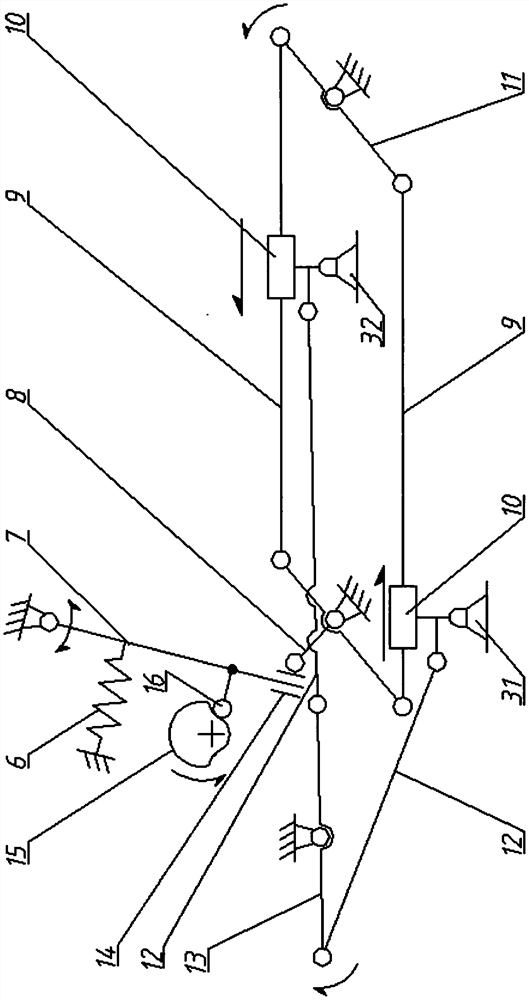

[0049] A feeder that includes two sets of paper delivery nozzles, such as Figure 1 ~ Figure 3 As shown, there are paper loose blowing nozzle 1, component A paper nozzle 21, component B paper nozzle 22, group A paper delivery nozzle 31, group B paper delivery nozzle 32, paper delivery nozzle moving and leaving device.

[0050] Described loose paper blowing nozzle 1, A component paper nozzle 21, B component paper nozzle 22 front sides are all provided with blowing holes 23, and described loose paper blowing nozzle 1 is arranged on A component paper nozzle 21, On the left side of the B component paper nozzle 22, the A component paper nozzle 21 and the B component paper nozzle 22 are installed on the same plane, and the A group paper delivery nozzle 31 and the B group paper delivery nozzle 32 Set on the right side of A component paper nozzle 21 and B component paper nozzle 22.

[0051] The movement of the paper nozzles of the group A and the paper nozzles of the group B are the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com